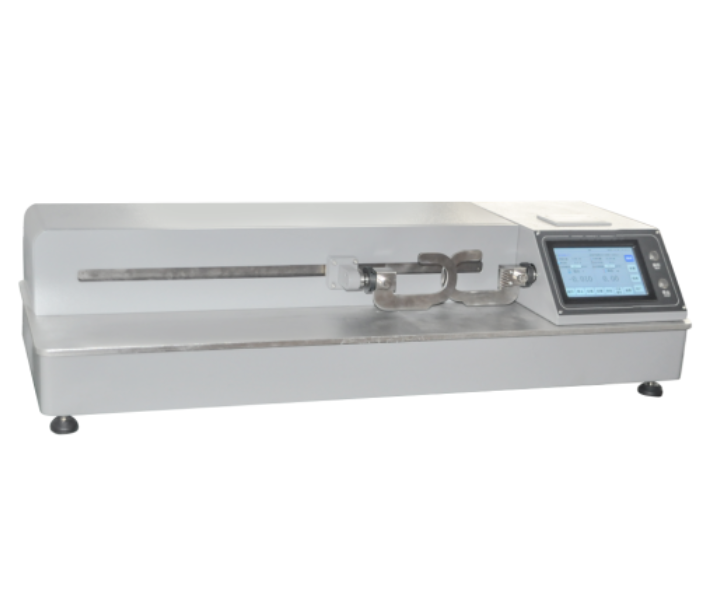

Sock Lateral and Vertical Extension Tester

The G831A Sock Lateral and Vertical Extension Tester is designed to measure the transverse and longitudinal stretching performance of various types of socks. It provides accurate data on elongation, tensile strength, elasticity, and deformation characteristics.

Application

The tester is suitable for:

Cotton, wool, nylon, and blended socks

Sports socks, fashion socks, and medical compression socks

Evaluation of sock elasticity, stretch recovery, tensile strength, and dimensional stability

Quality control in sock manufacturing and textile laboratories

Standards

The G831A Sock Lateral Tester complies with the following national and international standards:

(1) FZ/T 73001 – Sock testing methods (China)

(2) FZ/T 73011 – Determination of elongation and tensile properties of hosiery (China)

(3) FZ/T 70006 – Sock performance and quality standards (China)

(4) ASTM D4964 – Standard test method for hosiery stretch properties (USA, optional)

(5) ISO 13934-1 – Textiles – Tensile properties of fabrics (International, optional)

Parameters

| Parameter | Specification |

|---|---|

| Force range | 0.1 – 50 N |

| Force accuracy | ≤ ±0.2% F·S |

| Elongation range | 0.1 – 500 mm |

| Elongation accuracy | ≤ ±0.1 mm |

| Time setting | 0.1 – 999.99 min |

| Test speed | 2400 ± 10 mm/min |

| Elongation resolution | 0.1 mm |

| Effective stroke | 500 mm |

| Clamping distance | 100 – 500 mm, digitally adjustable |

| Dimensions (L×W×H) | 1100 × 350 × 280 mm |

| Power supply | AC 220 V, 50 Hz |

| Weight | Approx. 50 kg |

Features

Large color touch screen with Chinese/English menu interface

Data deletion, export to Excel, and integration with enterprise management software

Software analysis: fracture point, yield point, stress point, initial modulus, elastic/plastic deformation

Safety protections: limit, overload, negative force, overcurrent, overvoltage

Force calibration via digital code (authorized code)

Dual control (main unit and PC) for convenience and rich testing output (reports, curves, graphics, tables)

Modular design for easy maintenance and upgrades

Fully configurable parameters: elongation, force, test speed, and clamping distance

Online function support with built-in printer for reports and curve printing

Accessories

(1) Main unit – 1 pc

(2) Product certificate – 1 pc

(3) User manual – 1 pc

(4) Delivery note – 1 pc

(5) Acceptance form – 1 pc

Test Procedures

Install the sock sample between the clamps and set the desired clamping distance.

Configure test parameters: force, elongation, and speed via the touch screen.

Start the test; the system automatically applies force and records elongation.

Monitor data in real-time; view force-extension curves and other calculated parameters.

Export results to Excel or print via the built-in printer.

Perform calibration as necessary before testing to ensure accuracy.

Maintenance Information

Regularly inspect clamps and moving components for wear.

Clean the instrument surfaces and sample holders to avoid residue build-up.

Periodically verify force calibration and sensor accuracy.

Keep the instrument in a dry, dust-free environment.

Lubricate mechanical parts as per manual instructions to maintain smooth operation.

FAQ

What is this product?

A precision instrument for measuring transverse and longitudinal stretching of socks.

What is it used for?

To evaluate elasticity, elongation, tensile strength, and deformation characteristics of socks.

Why is it important?

Ensures product quality, comfort, and durability in sock manufacturing.

Which industries is it suitable for?

Hosiery manufacturing, textile laboratories, sportswear, and fashion textile industries.

What types of products can be tested?

Cotton, wool, nylon, blended socks, sports socks, fashion socks, and compression socks.

Leave Message Get Price