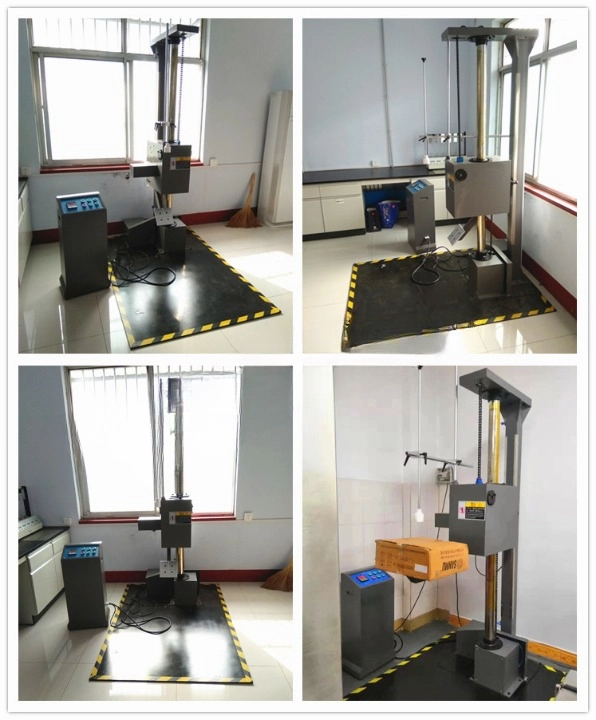

Carton Drop Tester

The Carton Drop Tester is designed to perform free-fall tests on packaging surfaces, corners, and edges to evaluate product durability during transportation and handling. Equipped with a digital height display and encoder-based height tracking, it ensures that the actual drop height deviates from the preset height by no more than 2% or 10 mm. The tester provides reliable data on the impact resistance of packaged products.

Applications

(1) Drop testing of cartons, boxes, and packaged goods.

(2) Evaluation of product packaging resistance to shocks during transport and handling.

(3) Determining the weakest surfaces, edges, and corners of packages.

(4) R&D for packaging materials and design optimization.

(5) Quality control in logistics, shipping, and e-commerce industries.

Standards

(1) ISO 248 – Packaging – Complete, filled transport packages – Drop test method.

(2) JIS Z0202-87 – Packaging – Drop test for packages.

(3) GB/T 4857.5-92 – Packaging — Transport package testing methods — Part 5: Drop test.

Parameters

| Parameter | Specification |

|---|---|

| Drop Height | 300 – 1500 mm |

| Measurable Weight | ≤100 kg |

| Maximum Sample Size | 800 × 800 × 800 mm |

| Impact Panel Size | 1700 × 1200 mm |

| Support Arm Size | 160 × 180 × 8 mm |

| Drop Angle Error | ≤1° |

| Drop Height Error | ±10 mm |

| Test Bench Dimensions | 1700 × 1200 × 2350 mm |

| Control Box Dimensions | 350 × 300 × 800 mm |

| Structure Type | Single-arm, dual-column |

| Lifting Mechanism | Electric lifting and drop |

| Buffer System | Hydraulic cushioning for smooth and safe operation |

Features

(1) Single-arm, dual-column structure with electric lifting, electric drop, and electric reset for easy operation.

(2) Hydraulic cushioning ensures smooth operation, enhances durability, and improves safety.

(3) Accurate digital height measurement with encoder tracking; deviation within ±10 mm or 2% of preset height.

(4) Drop angle error less than 5° between impact surface and base plate.

(5) Adjustable support arm to facilitate placement of samples of various sizes.

(6) Suitable for a wide range of packaged products, including cartons, boxes, and other fragile items.

Accessories

(1) Digital height display unit

(2) Hydraulic buffer system

(3) Encoder for height tracking

(4) Electric lifting and drop mechanism

(5) Control cabinet with interface for setting drop height and angle

(6) Safety interlocks and emergency stop system

Test Procedures

Place the packaged sample on the support arm.

Set the drop height using the digital interface or encoder-controlled display.

Confirm the impact surface and sample alignment; ensure drop angle ≤5°.

Initiate the test by triggering the electric release.

After impact, examine the sample for damage to corners, edges, and surfaces.

Record observations and compare with preset acceptance criteria.

Repeat as required for multiple orientations (face, edge, corner).

Adjust height or sample orientation for subsequent tests.

Maintenance Information

(1) Regularly inspect hydraulic buffer and support arms for wear or leaks.

(2) Calibrate digital height display and encoder periodically to ensure accuracy.

(3) Keep impact surfaces clean and free from debris.

(4) Lubricate moving parts and columns according to manufacturer recommendations.

(5) Check safety interlocks and emergency stop mechanisms before each test.

FAQ

What is this product?

A laboratory tester for evaluating the impact resistance of cartons and packaged goods via controlled drops.

What is it used for?

To simulate transport and handling conditions, assessing packaging durability and impact resistance.

Why is it important?

Ensures products are adequately protected during shipment, reducing damage and returns.

Which industries can use it?

Packaging design, logistics, e-commerce, electronics, food and beverage, and consumer goods.

What types are available?

Single-arm or dual-arm drop testers with electric lifting, hydraulic buffering, and digital height tracking.

Leave Message Get Price