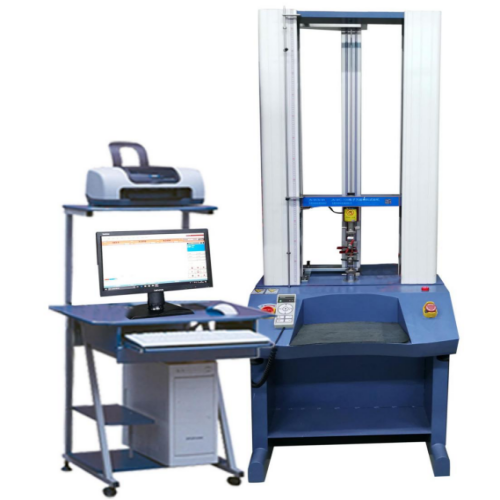

Automotive Wiring Harness Load Comprehensive Test Bench

The Automotive Wiring Harness Load Comprehensive Test Bench is a multifunctional testing platform designed for evaluating the electrical and thermal performance of automotive wiring harnesses and connectors. It enables simultaneous measurement of voltage drop, temperature rise, and overload/short-circuit conditions, ensuring compliance with automotive industry standards. The system is suitable for both production line quality control and laboratory testing.

Application

This test bench is widely used for:

Automotive wiring harnesses for voltage drop, current carrying capacity, and short-circuit testing

Connectors and terminals to verify proper electrical and thermal performance

Electrical system validation for passenger cars, commercial vehicles, and specialized vehicles

R&D and quality assurance in automotive electronics and wiring harness manufacturing

The system allows testing under single-loop or multi-loop configurations, supporting both serial and parallel current paths to simulate real-world operating conditions.

Standards

The test bench complies with multiple international and regional standards:

(1) ISO 8092.1 – 8092.4 — Road vehicles — Electrical wiring harnesses

(2) QC/T 417.1 – 417.5-2001 — Vehicle wiring harness and connector testing

(3) SAE J1128 — Low voltage automotive wiring

(4) ISO 6722 — Electrical cables — Dimensions, test methods, and performance

(5) IEC 60512 — Connectors for electrical and electronic equipment

(6) GB/T 2423.1 — Environmental testing for electrical components

Parameters

| Item | Specification |

|---|---|

| Input voltage | AC 220V ±10%, 50Hz |

| Working current | DC 0~500A, adjustable |

| Current output mode | Constant current |

| Voltage drop detection | 8 channels, 0.01~199.99mV |

| Temperature rise measurement | 8 channels, thermal sensors included |

| Power | 7.5 kW |

| Maximum output voltage | 15V |

| Circuit configuration | Single-loop, series, and parallel options |

| Short-circuit detection | Single-loop automatic detection |

| Control & recording | Integrated data logging for voltage and temperature |

Features

Multi-loop measurement: Simultaneous voltage drop and temperature rise detection for up to 8 circuits.

Overload protection: Supports serial and parallel load configurations to simulate real-world electrical stresses.

High precision: Voltage drop range down to 0.01 mV with accurate temperature monitoring.

Automated short-circuit detection: Ensures safety and prevents damage to the harness or connectors.

Data recording and export: Integrated data logging allows long-term analysis and reporting.

Flexible configuration: Supports multiple wiring harness designs and custom test setups.

Industrial-grade build: Stable operation under continuous testing conditions with high reliability.

Accessories

(1) 8-channel voltage drop measurement module

(2) 8-channel temperature rise sensors

(3) Connection clamps for single-loop and multi-loop wiring

(4) Safety fuses and circuit breakers

(5) Data acquisition and control software

(6) Optional PC interface for real-time monitoring

Test Procedures

Connect the wiring harness or connector to the test bench using provided clamps.

Configure the test parameters: working current, number of loops, test duration, and measurement channels.

Start the test sequence to simultaneously record voltage drop, temperature rise, and overload conditions.

For series or parallel configurations, verify total current flow against set values.

Monitor the test on the display or PC interface. Automatic short-circuit detection will stop the test if necessary.

Upon completion, review recorded data and export for analysis or reporting.

Disconnect the test harness and prepare the system for the next test.

Maintenance Information

Regularly inspect electrical connections and clamps for wear or oxidation.

Verify calibration of voltage and temperature sensors periodically.

Keep the workbench clean and free from dust or debris.

Ensure cooling fans or ventilation systems operate correctly to prevent overheating.

Perform software updates and backup test data routinely.

FAQ

What is this product?

A test bench for evaluating the electrical and thermal performance of automotive wiring harnesses and connectors.

What is it used for?

Measures voltage drop, temperature rise, overload, and short-circuit conditions to verify performance and safety.

Why is it important?

Ensures automotive wiring harnesses and connectors meet electrical safety standards and perform reliably under load.

Which industries use this product?

Automotive manufacturing, wiring harness production, automotive R&D, and electrical system testing.

What types are available?

Multi-loop test benches with 8 or more circuits, single-loop test benches, and custom-configured systems for high-current applications.

Leave Message Get Price