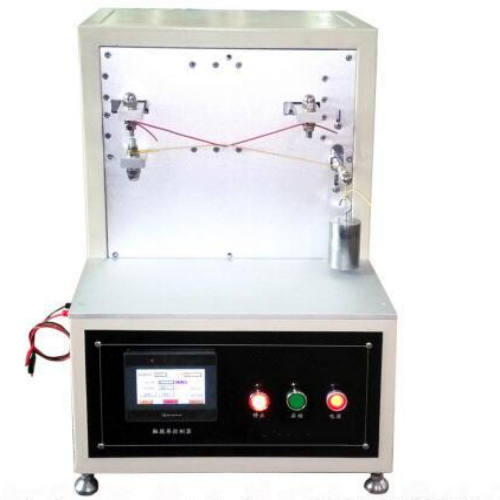

Automotive Wire Vibration Abrasion Test Machine

The Automotive Wire Vibration Abrasion Test Machine is designed to evaluate the insulation durability and abrasion resistance of automotive wires (≤6mm²) under repetitive vibration conditions. It simulates real-world wire-to-wire contact and friction in harness assemblies, allowing engineers to assess potential wear, insulation damage, and electrical continuity failure. The system ensures precise control of vibration frequency, amplitude, and test duration, providing reliable and repeatable results for R&D, quality assurance, and compliance testing. It is particularly suited for assessing long-term durability of automotive wires under mechanical stress.

Application

The machine is widely used in automotive and electrical wire industries for:

Automotive wire harness testing: Evaluating abrasion resistance between individual wires under vibration.

R&D and quality control: Ensuring wires meet insulation durability requirements before production or deployment.

Electrical performance validation: Determining the point of insulation failure and continuity loss under dynamic vibration.

Material testing: Studying insulation coatings, wire jacketing materials, and composite wire assemblies.

Extended applications: Applicable to railway, industrial, and electronic cable assemblies subjected to vibration stresses.

Typical test samples include automotive power and control wires, harness bundles, and low-voltage cables with diameters ≤6mm².

Standards

The test machine meets domestic and international standards:

(1) VW60306:2000-11 — Vibration and abrasion resistance for automotive wiring

(2) GS95007-1:2007-08 — Automotive wire vibration abrasion test

(3) ISO 6722 — Road vehicles: Low-voltage primary cables

(4) SAE J1128 — Automotive low-voltage cable standard

(5) IEC 60227 / IEC 60228 — Insulated cables and conductors

(6) GB/T 2423.10 — Environmental testing for electrical and electronic equipment: vibration

By adhering to these standards, the machine ensures accurate, repeatable, and internationally recognized test results.

Parameters

| Item | Specification |

|---|---|

| Applicable wire size | ≤6mm² |

| Vibration frequency | 10Hz |

| Vibration amplitude | 6.35 ± 0.25 mm |

| Vibration direction | Horizontal |

| Fixed wire support spacing | 280 mm |

| Moving wire support | One support on fixed table, one through guide shaft >14× sample diameter |

| Vibration table to fixed table gap | 45 mm |

| Friction contact point | Sample midpoint (10% of length) |

| Load weights (N) | 10, 12.5, 15, 20 (selectable) |

| Abrasion cycles | 1–9999 (programmable) |

| Automatic stop | Upon wire-to-wire electrical conduction / insulation failure |

| Power supply | 220V/50Hz |

| Control | PLC + Touchscreen (optional) |

Features

Precise Vibration Control: Stable horizontal vibration with adjustable frequency and amplitude for consistent testing.

Wire-to-Wire Simulation: Accurately reproduces real-world friction between adjacent wires under mechanical stress.

Programmable Cycles: Test cycles can be set from 1 to 9999 with automatic stop upon insulation failure.

Adjustable Loading: Multiple load options (10–20 N) allow simulation of varying wire harness conditions.

Automatic Safety Stop: Machine halts immediately when wire insulation breaks and conduction occurs, preventing damage.

Robust Construction: Durable vibration table and supports designed for long-term operation.

User-Friendly Operation: PLC-controlled touchscreen interface allows easy setup, monitoring, and data logging.

Repeatable Results: Ensures reproducibility for quality assurance and certification purposes.

Accessories

(1) Set of load weights (10N, 12.5N, 15N, 20N)

(2) Guide shafts and friction contact points

(3) Sample clamps for fixed and moving wires

(4) PLC touchscreen controller with software

(5) Optional data acquisition system for cycle count and failure recording

(6) User manual and calibration certificate

Test Procedures

Mount test wires securely on fixed and moving supports according to the sample diameter and length.

Select the appropriate load weight and friction contact point.

Program the vibration frequency, amplitude, and number of cycles via touchscreen interface.

Start the test; monitor wire abrasion and insulation status in real time.

The machine automatically stops when wire-to-wire conduction occurs or after the preset cycles are completed.

Inspect wire insulation for wear, cracking, or failure and record the results.

Optionally, export data logs for reporting and further analysis.

Maintenance Information

Regularly inspect vibration table, supports, and friction points for wear or damage.

Clean the machine after each test to prevent debris accumulation.

Lubricate guide shafts and moving components periodically.

Check PLC and electrical components for stable operation.

Verify load weights and clamps for proper attachment.

Ensure automatic stop mechanisms are functional before each test.

FAQ

What is this product?

A test machine designed to simulate wire-to-wire vibration and evaluate insulation abrasion in automotive cables.

What is it used for?

To determine the durability and wear resistance of automotive wires under vibration stress and friction conditions.

Why is it important?

Ensures wire harness reliability, prevents insulation failure, and guarantees safety in automotive applications.

Which industries use this product?

Automotive, transportation, wire production, R&D laboratories, and quality control departments.

What types are available?

Horizontal vibration standard model, programmable cycle model, optional data acquisition and monitoring systems.

Leave Message Get Price