Multi-Function Scratch Tester

The Multi-Function Scratch Tester integrates three commonly used automotive industry testing methods—Five-Finger Scratch, Cross-Cut (100-grid) Scratch, and Plastic Finger Scratch—into a single instrument. It is designed to evaluate the scratch resistance of various automotive interior materials, including plastics, rubber, leather, textiles, coated and uncoated materials, as well as paints, inks, and soft metals. The instrument delivers highly repeatable test data, aiding manufacturers in production control and performance verification.

Application

(1) Scratch resistance testing of automotive interior plastics, rubbers, leathers, and textiles.

(2) Evaluation of coated and uncoated materials, composite materials, paints, and inks.

(3) Laboratory and production quality control for interior components.

(4) Material performance assessment for R&D in automotive, consumer electronics, and industrial applications.

(5) Simulating real-world wear conditions with multiple scratch methods.

Standards

(1) PV 3952 – Scratch Resistance of Plastic Interior Components

(2) Ford BN 108-03, 13 – Scratch Resistance Test

(3) BMW 0180 PA-P 028 – Cross-Cut Scratch Test

(4) BMW GS 97034-9, PA 0015 – Scratch Resistance Test

(5) DAF KEUR 00824-401 – Cross-Cut Scratch Test

(6) DAF KEUR 00824-402 – Scratch Resistance Test

(7) GME 60401 – Cross-Cut Scratch Test

(8) GM 14829 – Cross-Cut Scratch Test

(9) Jaguar-Landrover TPJLR.52.004 – Scratch Resistance Test

(10) GM N 3943 – Five-Finger Scratch Test for Plastics

(11) LP 463DD-18-01 – Scratch and Abrasion Resistance, Five-Finger Method

(12) GMW14130.14688 – Scratch Resistance Test

(13) 83502SDA-9000 – Scratch Test

(14) NES M N0159 – Polypropylene Interior Component Scratch Test

Parameters

| Parameter | Specification |

|---|---|

| Test Modes | Five-Finger / Cross-Cut (100-grid) |

| Test Speed | 10 – 200 mm/s |

| Stroke | Cross-Cut: 25 / 40 / 45 mm; Five-Finger: 10 – 200 mm |

| Number of Scratches | User-settable |

| Scratch Head Size | Interchangeable |

| Scratch Head Lift | Pneumatic |

| Weight | 95 kg |

| Speed Buffer | 10 ±1 mm |

| Control Interface | Intelligent Touchscreen |

| Dimensions (W×D×H) | 950 × 550 × 650 mm |

| Power Supply | 220 V / 50 Hz |

Features

(1) Integrates multiple automotive scratch testing methods in a single unit.

(2) Intelligent touchscreen for easy operation and process monitoring.

(3) Interchangeable scratch heads for different test requirements.

(4) Pneumatic lift ensures precise application of scratch force.

(5) Adjustable speed and stroke to simulate real-world conditions.

(6) High repeatability and reliability suitable for both R&D and production QC.

(7) Supports evaluation of plastics, rubbers, leathers, textiles, coatings, and composite materials.

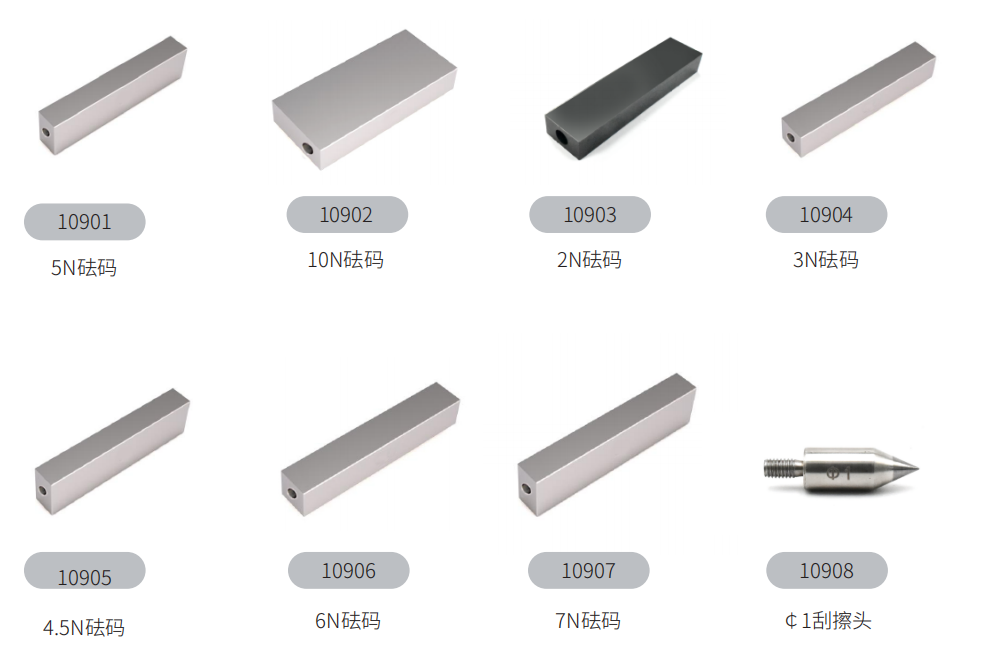

Accessories

(1) Set of scratch heads for Five-Finger Method

(2) Set of scratch heads for Cross-Cut Method

(3) Sample fixture

(4) Load weights and calibration kit

(5) Touchscreen controller

Test Procedures

Install the sample on the fixture and secure it properly.

Select the test method (Five-Finger or Cross-Cut) via the touchscreen interface.

Set the desired speed, stroke, and number of scratches.

Start the test; the instrument will perform automatic scratch cycles.

After completion, inspect the sample for scratch depth, number, and coating detachment.

Record results and compare with reference standards.

Maintenance Information

(1) Regularly clean scratch heads and sample fixture after testing.

(2) Check pneumatic lift system for air leaks or pressure deviations.

(3) Lubricate moving parts as recommended by the manufacturer.

(4) Inspect electrical connections and touchscreen functionality.

(5) Store in a dry, dust-free environment to prevent damage.

FAQ

What is this product?

It is a Multi-Function Scratch Tester for evaluating scratch resistance of automotive interior and other materials.

What is it used for?

To measure scratch performance and durability for plastics, rubbers, leathers, textiles, coatings, and composite materials.

Why is it important?

Ensures product quality, surface durability, and compliance with automotive scratch resistance standards.

Which industries is it suitable for?

Automotive interiors, material R&D laboratories, quality control, plastics, leather, and coatings industries.

What are the similar products?

Taber Scratch Tester, Cross-Cut (100-grid) Scratch Tester, Five-Finger Scratch Tester.

Leave Message Get Price