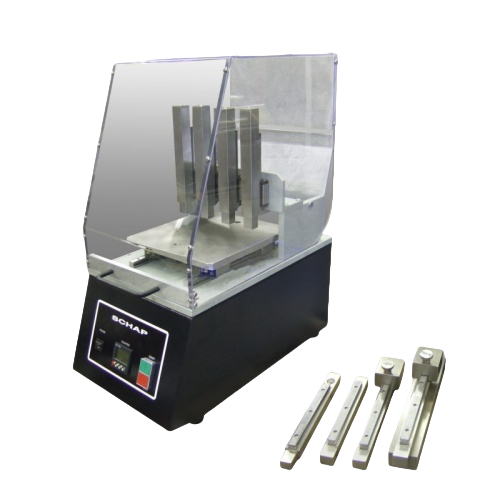

Four-Station Abrasion Tester

The Four-Station Abrasion Tester is a specialized tribological testing system designed to evaluate the wear resistance of materials. The instrument features four independent test stations, allowing parallel testing of multiple samples. It is designed according to Nissan Standard NES M0155 2008-N, clauses 15, 16, and 31, providing reproducible and precise abrasion performance data for materials used in automotive and industrial applications.

Application

The tester is used for wear resistance evaluation of the following materials:

Automotive interior materials, plastics, and polymers

Coatings and surface-treated materials

Metal and composite components subject to frictional wear

Seal materials and elastomers

Typical Test Applications Include:

Assessment of friction and wear characteristics under defined loads

Material selection and R&D for durability improvement

Verification of supplier compliance with OEM wear specifications

Routine quality control and acceptance testing

Standards

The system is designed in compliance with the following standards:

(1) Nissan NES M0155 2008-N, Clause 15 – Material Wear Test

(2) Nissan NES M0155 2008-N, Clause 16 – Surface Durability Evaluation

(3) Nissan NES M0155 2008-N, Clause 31 – Coating Wear Performance

Parameters

| Parameter | Unit | Value |

|---|---|---|

| Number of test stations | – | 4 |

| Cycle speed | CPM | 50 – 60 (variable) |

| Stroke | mm | 50 – 100 (variable) |

| Applied weight | N | 12.9 – 61.3 |

| Product weight | lbs / kg | 120 lbs / 54 kg |

| Power supply | – | To be specified at order |

Features

Four independent test stations for parallel specimen testing

Mechanical components made from non-corrosive aluminum and stainless steel

Durable powder-coated and anodized surface finishes

Precision ball and needle bearings for accurate and stable motion

Programmable up-count controller with automatic stop function

Adjustable slow-speed and test-speed operation

Ventilated safety enclosure to protect operators from pinch points

High-quality brushless motor for reliable performance

One-year manufacturer warranty

Accessories

(1) Sample holder set for four test stations

(2) Adjustable weight set for variable load application

(3) Protective ventilation cover

(4) Control software and interface for speed and cycle programming

Test Procedures

Mount test specimens securely on each of the four stations.

Adjust stroke length, applied load, and cycle speed according to test requirements.

Start the test using the programmable control interface.

Monitor cycles and ensure automatic stop occurs at the programmed count.

Remove specimens and assess wear patterns, mass loss, or surface degradation.

Record all data for documentation and comparison against standards.

Maintenance Information

Regularly clean and lubricate bearings and moving parts.

Inspect sample holders and applied weights for wear or damage.

Verify cycle counter and speed accuracy periodically.

Keep safety enclosure clean and ensure proper ventilation.

Disconnect power supply during maintenance or long-term storage.

FAQ

1. What is this product?

It is a four-station abrasion tester designed to evaluate material wear resistance under controlled conditions.

2. What is it used for?

It is used to test the durability of materials, coatings, and surface treatments by simulating repeated frictional wear.

3. Why is this product important?

Wear resistance is critical for ensuring longevity and reliability of automotive components and industrial materials.

4. Which industries is it suitable for?

Automotive, aerospace, industrial machinery, coatings, and polymer material manufacturing.

5. What are similar products?

Single- or multi-station abrasion testers

Taber Abrasion Tester

Pin-on-disk tribometers

Leave Message Get Price