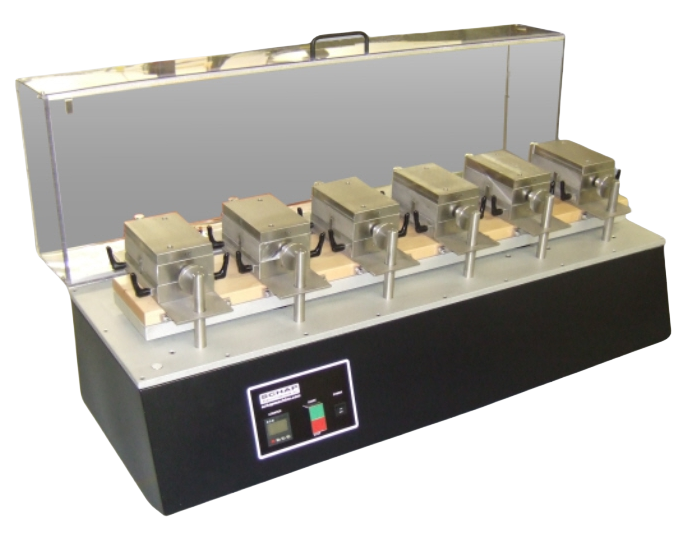

Fabric Pilling and Abrasion Tester

The Fabric Pilling and Abrasion Tester is a six-station test instrument designed to evaluate the resistance of fabrics and leathers to pilling, fuzzing, and surface wear. By subjecting test specimens to controlled rubbing cycles against defined abrasive materials, the system provides reproducible and comparable results for assessing surface durability and appearance retention in accordance with international and OEM standards.

Application

The tester is used for pilling and abrasion performance evaluation of the following test products:

Woven and knitted textile fabrics

Upholstery fabrics for automotive interiors

Apparel fabrics and garment materials

Leather and synthetic leather materials

Interior trim materials for automotive and transportation applications

Typical Test Applications Include:

Comparison of fabric pilling grades after defined abrasion cycles

Verification of material compliance with OEM specifications

Incoming material inspection and supplier qualification

Research and development of new textile and leather materials

Routine quality control testing in laboratories and production environments

Standards

The test system complies with or is designed in reference to the following standards:

(1) ASTM D3511 – Standard Test Method for Pilling Resistance of Textiles

(2) Ford BN 125-01 – Fabric Pilling Resistance Test Method

(3) Ford BN 108-03 – Fabric Abrasion and Pilling Test Specification

(4) Ford BN 108-14 – Leather Pilling and Wear Test Specification

(5) GM 9652 – Textile Surface Wear and Pilling Test

(6) TPJLR.52.005 – Jaguar Land Rover Interior Material Pilling Test

Parameters

| Parameter | Unit | Value |

|---|---|---|

| Number of test stations | – | 6 |

| Product weight | lbs / kg | 240 lbs / 109 kg |

| Overall dimensions | inch | 48 × 19 × 18 |

| Equipment footprint | inch | 24 × 50 × 30 |

| Abrasion cycles | – | Programmable |

| Speed control | – | Adjustable test and slow speed |

| Power supply | – | To be specified at order |

Features

Six independent test stations for parallel specimen testing

Compatible with multiple abrasive materials (brush, sponge, hook-and-loop, etc.)

Precision ball and needle bearings ensure stable and repeatable motion

Non-corrosive aluminum and stainless steel mechanical components

Durable powder-coated and anodized surface finishes

Programmable up-count controller with automatic stop function

Adjustable low-speed and test-speed operation

Ventilated safety enclosure to protect operators from pinch points

High-quality brushless motor for long service life

One-year manufacturer warranty

Accessories

(1) Ford Leather Test Kit (BN 108-14): low-profile board and six adjustable stainless steel 25 lb specimen holders

(2) Ford Fabric Test Kit (BN 108-03): three low-profile boards (nylon brush, sponge, hook-and-loop) and six specimen holders

(3) ASTM Fabric Test Kit (ASTM D3511): brush board and six ASTM circular specimen holders

(4) Load and tool storage stand with height-adjustable extruded aluminum frame

Test Procedures

Prepare and mount test specimens onto the designated specimen holders.

Select and install the required abrasive material according to the test standard.

Set the test speed and number of abrasion cycles.

Start the test and allow the machine to run automatically until completion.

Remove specimens and visually evaluate pilling or fuzzing against standard rating images or internal criteria.

Record and document test results.

Maintenance Information

Regularly inspect specimen holders and abrasive boards for wear

Keep bearings and moving parts clean and free from debris

Verify speed and cycle counter accuracy periodically

Store accessories on the dedicated load stand when not in use

Disconnect power supply during maintenance or long-term storage

FAQ

1. What is this product?

It is a laboratory test instrument used to evaluate fabric and leather resistance to pilling and surface abrasion.

2. What is it used for?

It is used to assess surface durability, fuzzing, and pilling performance of textile and leather materials under controlled abrasion conditions.

3. Why is this product important?

Pilling resistance directly affects product appearance and perceived quality, especially in automotive interiors and apparel applications.

4. Which industries is it suitable for?

Textile manufacturing, automotive interior suppliers, apparel brands, leather manufacturers, and material testing laboratories.

5. What are similar products?

Martindale abrasion and pilling testers

Random tumble pilling testers

Fabric surface wear and durability test systems

Leave Message Get Price