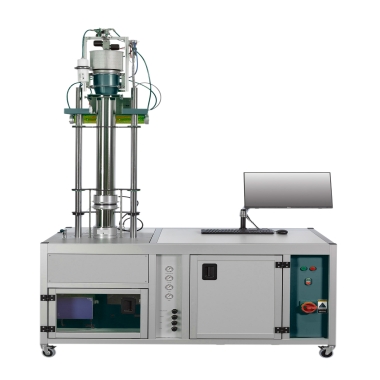

Test System for multiple parameter testing at filter media

The Test System for multiple parameter testing of filter media is designed to evaluate key performance characteristics of flat sheet filter media, including differential pressure, gravimetric filtration efficiency, fractional efficiency, and dust holding capacity. The vertical-oriented flow channel provides a space-saving design while ensuring reproducible and reliable results. This test bench combines a simple, robust setup with manual operation, making it cost-efficient while maintaining high testing accuracy. It is especially suitable for filter media testing according to ISO 5011 and other international standards.

Application

(1) Quality assurance of flat sheet filter media for final inspection before shipping or receiving inspection.

(2) Performance evaluation of filter materials during research and development.

(3) Measurement of differential pressure characteristics for various filter media.

(4) Determination of gravimetric and fractional filtration efficiency.

(5) Dust holding capacity assessment under standardized aerosol loading conditions.

(6) Testing of filter media for automotive, industrial, and HVAC applications.

Standards

(1) ISO 29463-3 — High-efficiency air filter testing.

(2) ISO 29463-5 — Determination of particle filtration efficiency.

(3) ISO 5011 — Air filters for internal combustion engines and industrial machinery.

(4) EN 13274-7 — Air filter testing methods for particulate separation.

Features

(1) Vertical flow channel design for compact footprint and space efficiency.

(2) Reliable and reproducible testing of differential pressure, dust holding capacity, and gravimetric and fractional filtration efficiency.

(3) Separate removable holders for test filter and backup filter, enabling weighing without removing the filter.

(4) Backup filter protects the flow rate unit in case of filter breakthrough.

(5) Integrated solid aerosol generator (SAG 410) with adjustable feed rates (1.5–20 g/h).

(6) Flexible control of solid aerosol generation and injector nozzle for uniform dust dispersion.

(7) Manual operation ensures simple, cost-effective handling while maintaining test accuracy.

Parameters

| Parameter | Unit | Value |

|---|---|---|

| Test flow rate | m³/h | 1.5 – 18 |

| Measuring range, differential pressure | Pa | 0 – 5000 |

| Compressed air supply | bar | 6 |

| Power supply | – | 110 – 230 VAC, 50/60 Hz |

| Operating medium (aerosol) | – | DEHS, ISO 12103-1 A2 |

| Test specimen dimensions | – | Flat sheet filter media (customizable) |

| Environmental condition, temperature | °C | 0 – 50 |

| Environmental condition, relative humidity | % | 0 – 100 |

| System dimensions (W × H × D) | mm | 1500 × 1000 × 2000 |

| Weight | kg | approx. 250 |

Test Procedures

(1) Install the test filter and backup filter in their respective holders.

(2) Configure the flow rate and aerosol feed parameters according to the test standard.

(3) Activate the solid aerosol generator and ensure uniform particle dispersion in the vertical flow channel.

(4) Start the test sequence to measure differential pressure, dust holding capacity, gravimetric efficiency, and fractional efficiency.

(5) Record data continuously or at defined intervals.

(6) Weigh test and backup filters if required to determine dust loading.

(7) Generate automated or manual reports for R&D, QA, or production documentation.

Maintenance Information

(1) Clean aerosol generator and flow channel after each test session.

(2) Periodically calibrate differential pressure sensors and aerosol measurement instruments.

(3) Inspect filter holders and seals for wear or deformation.

(4) Verify functionality of the backup filter and flow rate control system.

(5) Ensure compressed air supply and electrical connections are stable before testing.

FAQ

(1) What is this product?

– A test system for multiple parameter evaluation of flat sheet filter media, measuring differential pressure, dust holding capacity, and filtration efficiency.

(2) What is it used for?

– To characterize filter media performance for quality assurance, R&D, and production control in accordance with ISO 5011 and other standards.

(3) What types of this product exist?

– Configurations for flat sheet media, small filter elements, and custom test setups for specific R&D requirements.

(4) What industry problems does it solve?

– Ensures accurate and reproducible assessment of filter media, supports QA during production, and validates material performance for automotive, industrial, and HVAC applications.

(5) How is it operated?

– Mount the filter, set flow and aerosol parameters, run the test manually, measure efficiency and dust loading, and record results for analysis.

Leave Message Get Price