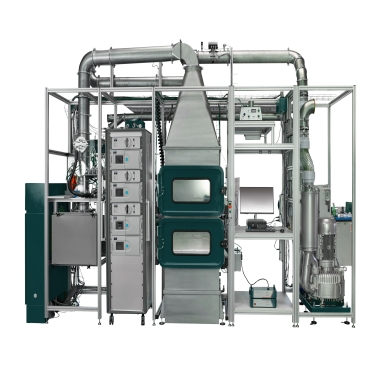

Fuel Cell Air Intake Filter Test System

The Fuel Cell Air Intake Filter Test System is a specialized test bench for evaluating air intake filters used in fuel cells. It is designed for both particle-based and gas-based testing, supporting combination filters with high airflow and large dimensions. The system allows precise measurement of differential pressure, dust loading, fractional efficiency, and adsorption/desorption performance under controlled test conditions. Test elements of different designs and filter media can be mounted via adapters, providing reliable and reproducible data for research, development, and quality control.

Application

(1) Quality control during fuel cell air intake filter production.

(2) Research and development of new filter materials and element configurations.

(3) Benchmarking and comparative testing of different filter elements and media.

(4) Measurement of differential pressure curves under varying airflow conditions.

(5) Evaluation of dust loading and fractional efficiency using ISO 12103-1 test dust, DEHS, NaCl, or KCl aerosols.

(6) Gas adsorption and desorption testing for pollutants such as n-butane, toluene, sulphur dioxide, nitrogen dioxide, ammonia, hydrogen sulphide, and acetaldehyde.

(7) Simulation of real operating conditions for fuel cell air intake systems.

Standards

(1) ISO 11155-1 — Air filters for gas turbine and fuel cell applications — Part 1: Particle-based efficiency testing.

(2) ISO 11155-2 — Air filters for gas turbine and fuel cell applications — Part 2: Gas adsorption testing.

(3) DIN 71460-1 — Particle filtration testing of air filters.

(4) DIN 71460-2 — Gas adsorption testing of air filters.

Features

(1) Gas-tight test channels ensuring no leakage and accurate measurement.

(2) Modular structure enabling adaptation to various filter sizes and types.

(3) High degree of automation with software-controlled test sequences.

(4) Standardized automated report generation for documentation and traceability.

(5) Flexible filter adapter system allowing easy insertion and removal of filter elements.

(6) Multi-substance testing capability for both aerosols and pollutant gases.

Parameters

| Parameter | Unit | Value |

|---|---|---|

| Test flow rate | m³/h | 70 – 1400 |

| Differential pressure measuring range | Pa | ≤ 1000 |

| Test specimen dimensions | mm | ≤ 500 × 700 (bypass option: 100 cm²) |

| Operating medium (aerosols) | – | ISO 12103-1 A2 fine test dust, DEHS, NaCl, KCl |

| Operating medium (gases) | – | Nitrogen dioxide, hydrogen (others on request) |

| Operating medium (standard pollutant gas) | – | n-Butane (80 ppm), Toluene (80 ppm), Sulphur dioxide (30 ppm) |

| Operating medium (other pollutant gases) | – | Nitrogen dioxide (30 ppm), Ammonia (30 ppm), Hydrogen sulphide (0.4 ppm), Acetaldehyde (30 ppm) |

| Power supply | – | 3 × 400 VAC, 32 A, 50 Hz |

| Gas sensors | – | FID (organic substances), UV-fluorescence (sulphur dioxide), CLD (nitrogen oxides) |

| Other sensors | – | Temperature, relative humidity, barometric pressure |

| System dimensions (W×H×D) | mm | 5000 × 2750 × 3400 |

Test Procedures

(1) Install the filter element in the test duct using the filter adapter.

(2) Select test aerosol(s) or pollutant gas according to the desired standard and test purpose.

(3) Set flow rate, temperature, and humidity parameters.

(4) Initiate the automated test sequence via the software interface.

(5) Measure differential pressure, dust loading, fractional efficiency, and adsorption/desorption characteristics.

(6) Monitor gas sensor outputs for pollutant adsorption testing.

(7) Generate automated test reports for analysis, benchmarking, and documentation.

Maintenance Information

(1) Regular inspection and cleaning of test ducts, adapters, and aerosol/gas injection systems.

(2) Periodic calibration of differential pressure sensors, gas sensors, and airflow measurement devices.

(3) Software and automation system checks to ensure proper test sequence execution.

(4) Verification of system performance through routine validation tests after maintenance.

FAQ

(1) What is this product?

– A test system for fuel cell air intake filters, capable of particle and gas-based evaluation.

(2) What is it used for?

– To measure differential pressure, dust loading, fractional efficiency, and adsorption/desorption performance of fuel cell air intake filters.

(3) What types of this product exist?

– Configurations for various filter dimensions (≤ 500 × 700 mm), flow rates (70–1400 m³/h), and test media (aerosols and gases).

(4) What industry problems does it solve?

– Ensures fuel cell air intake filters meet particle and gas filtration performance standards.

– Provides reliable and reproducible test data for R&D and quality control.

– Enables benchmarking of different filter designs and materials.

(5) How is it operated?

– Mount the filter element on the adapter, select test aerosol or gas, set test parameters, start automated test sequence, monitor data via sensors, and generate test reports.

Leave Message Get Price