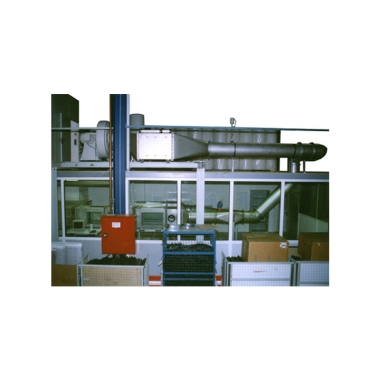

General ventilation equipment filter test bench

The General Ventilation Equipment Filter Test Bench (GVT 3000) is a fully automated system for evaluating indoor air filters used in HVAC and general ventilation applications. It precisely measures filtration efficiency, flow resistance, dust holding capacity, and particle classification (PM1, PM2.5, PM10). Equipped with a high-resolution light scattering spectrometer and advanced aerosol generation technology, the system ensures highly reproducible and internationally compliant results according to EN 779:2012, ASHRAE 52.2, and ISO FDIS 16890.

Application

(1) Testing of general ventilation filters in commercial, residential, and industrial HVAC systems.

(2) Measurement of initial resistance, flow-resistance curves, and gravimetric efficiency.

(3) DEHS-based particle counting efficiency testing (PM1).

(4) KCl/NaCl aerosol-based particle counting efficiency testing (PM2.5 and PM10).

(5) Dust holding capacity and filter final life assessment.

(6) R&D and certification testing of indoor air filters for international compliance.

(7) Comparative performance testing of domestic and imported filter media.

(8) Laboratory and production quality control for filter manufacturing.

Standards

(1) EN 779:2012 — Particulate air filters for general ventilation.

(2) ASHRAE 52.2 — Method of testing general ventilation air-cleaning devices for removal efficiency by particle size.

(3) ISO FDIS 16890 — Air filters for general ventilation — Testing and classification.

(4) EN 12341:1998 / EN 14907:2005 — PM2.5 and PM10 measurement standards.

(5) VDI 3491 — Metrological consistency in aerosol generation.

Features

(1) Modular design allowing adaptation to multiple international standards.

(2) Advanced aerosol generation with uniform particle distribution, supporting dusts (SAE A1–A4), salts (NaCl/KCl), oils (DEHS), and suspensions.

(3) High-resolution light scattering spectrometer (Promo® / Welas®) with up to 60 size classes per measurement range (0.2–10 µm, 0.2–100 µm).

(4) Patented fiber optic technology minimizing sampling loss.

(5) Fully automated operation via FTControl software for EN 779:2012, ASHRAE 52.2, and ISO FDIS 16890.

(6) High reproducibility and measurement accuracy for initial efficiency and fractional particle counts (PM1, PM2.5, PM10).

(7) Flexible and user-friendly operation requiring minimal training.

(8) Low maintenance, reliable, and cost-effective testing with validated individual component functionality.

Parameters

| Parameter | Unit | Value |

|---|---|---|

| Flow range | m³/h | 600 – 5400 |

| Measurement error | % | ≤ ±2 |

| Resistance range | Pa | 0 – 500 |

| Measuring device accuracy | Pa | 0–70 ≤ ±2; >70 ≤ ±3% |

| Aerosol uniformity | % | ≤ ±15 |

| Initial efficiency repeatability | % | <40 ≤ ±30 |

| Particle concentration indication error | % | 40–60 ≤ ±15; 60–80 ≤ ±8; 80–90 ≤ ±4; 90–99 ≤ ±2 |

| Efficiency range | % | ePM1 ≤ 99 (overall efficiency) |

| Total power consumption | kW | 18 |

| Main conduit | mm | 610 × 610, 304 stainless steel |

| Floor area | mm | 13000 × 2500 × 2500 |

| Filtration efficiency tests | – | Filter resistance, DEHS counting (PM1), KCl counting (PM2.5/PM10), gravimetric efficiency |

| Additional tests | – | Flow-resistance curve, dust holding capacity, filter final life test |

Test Procedures

(1) Install the filter specimen in the test bench fixture.

(2) Select appropriate aerosol type and concentration based on standard (DEHS, KCl/NaCl, or dust).

(3) Set target flow rate and differential pressure using FTControl software.

(4) Initiate automated test sequence; monitor differential pressure, particle size distribution, and flow rate.

(5) Record particle concentrations for feed gas and purified gas using high-resolution spectrometer.

(6) Generate test reports including efficiency curves, PM values, dust holding capacity, and filter resistance.

Maintenance Information

(1) Regularly clean aerosol generators, sampling lines, and spectrometer probes.

(2) Inspect and calibrate sensors, flow meters, and differential pressure devices periodically.

(3) Ensure FTControl software and electronics are updated and functioning correctly.

(4) Perform acceptance and verification testing after maintenance or component replacement.

FAQ

(1) What is this product?

– A fully automated test bench for evaluating indoor air filter performance, measuring efficiency, flow resistance, and particle separation.

(2) What is it used for?

– It measures filtration efficiency (PM1, PM2.5, PM10), flow-resistance, dust holding capacity, and final filter life according to EN 779:2012, ASHRAE 52.2, and ISO FDIS 16890.

(3) What types of this product exist?

– The system can be configured for different airflow ranges (600–5400 m³/h), aerosol types (DEHS, KCl/NaCl, dust), and particle spectrometer resolution ranges (0.2–100 µm).

(4) What industry problems does it solve?

– Ensures filters comply with international standards.

– Reduces sampling loss and measurement errors.

– Provides rapid, reproducible, and cost-effective performance evaluation for R&D, certification, and quality control.

(5) How is it operated?

– Place the filter in the test fixture, select aerosol type and flow rate, start automated testing, monitor particle concentrations in feed and purified gas, and generate test reports via FTControl software.

Leave Message Get Price