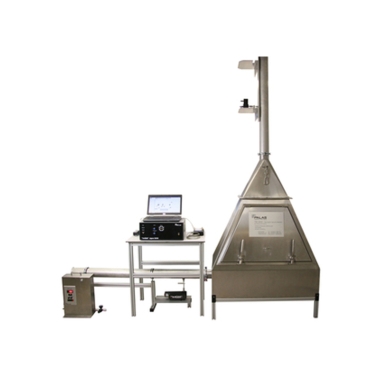

Vacuum Cleaner Filtration Testing System

The Vacuum Cleaner Filtration Testing System (TVE 3000) is a high-precision testing instrument designed to evaluate the filtration efficiency and staged separation performance of vacuum cleaners. It enables high-resolution particle measurement in both feed and purified gases, allowing accurate assessment of bagged vacuum cleaners, HEPA terminal filters, and complete vacuum cleaner systems. The system provides cost-effective, repeatable, and standards-compliant testing for research, development, and quality control.

Application

(1) Emission measurement of household and commercial vacuum cleaners.

(2) Evaluation of staged separation efficiency of bagged vacuum cleaners.

(3) Assessment of HEPA terminal filters in vacuum cleaner systems.

(4) Analysis of complete vacuum cleaner systems, including dust bags and HEPA filters.

(5) Filter development and R&D for vacuum cleaner manufacturers.

(6) Quality control and performance validation in production lines.

(7) Laboratory and research institute testing for product certification.

Standards

(1) EN 60312 — Methods for measuring vacuum cleaner emissions.

(2) ISO 29463 — High-efficiency filters and filter media for air.

(3) IEC 62821 — Particle measurement in airflow systems (supplementary guidance).

(4) ASTM F23 — Filtration testing standards for aerosol separation.

(5) GB/T 6165 — General methods for high-efficiency filter testing (China).

Features

(1) Simultaneous measurement of particles in feed and purified gases.

(2) High metrological consistency using RBG 1000 dust disperser or AGK 2000 salt generator.

(3) Measurement of particle size distribution and concentration in feed and clean gases.

(4) Accurate emission measurement according to EN 60312.

(5) Assessment of staged separation efficiency for dust bags, HEPA terminal filters, and complete vacuum cleaner systems.

(6) Easy operation, low maintenance, and reliable performance.

(7) Software-assisted multi-stage separation efficiency analysis with FTControl.

(8) Adjustable placement of dust disperser and purified gas sensors to study flow channel effects.

Parameters

| Parameter | Specification |

|---|---|

| Measuring range (particle size) | 0.2 – 40 µm |

| Measuring range (particle concentration) | <1 – 1,000,000 particles/cm³ |

| Power supply | 115/230 V, 50/60 Hz |

| External dimensions (H×W×D) | 2,100 × 2,600 × 600 mm |

| Weight | Approximately 170 kg |

| Compressed air supply | 6 – 8 bar |

| Volume flow rate | Depends on the vacuum cleaner |

| Dust disperser | RBG 1000 / optional AGK 2000 (salt disperser) |

| Particle sensors | 2070 (feed gas), 2300 (purified gas) |

| Software | FTControl, multi-stage efficiency calculation and report generation |

Test Procedures

(1) Install the vacuum cleaner in the testing chamber.

(2) Connect the dust disperser (RBG 1000) and adjust placement according to the flow channel layout.

(3) Start the vacuum cleaner and introduce dust or optional salt aerosols.

(4) Measure particle concentration and size distribution in the feed gas using the 2070 aerosol sensor.

(5) Measure purified gas particle concentration using the 2300 aerosol sensor.

(6) Use FTControl software to calculate staged separation efficiency for vacuum bags, HEPA filters, and complete systems.

(7) Generate test reports and store results in the software database.

Maintenance Information

(1) Regularly clean and calibrate dust dispersers and aerosol sensors.

(2) Inspect and maintain compressed air supply and tubing.

(3) Verify software updates and ensure FTControl is functioning correctly.

(4) Keep test chamber clean and free from residual dust to ensure measurement accuracy.

FAQ

(1) What is this product?

– The Vacuum Cleaner Filtration Testing System (TVE 3000) is a precision instrument used to measure filtration efficiency and staged separation performance of vacuum cleaners and their filters.

(2) What is it used for?

– It evaluates vacuum cleaner and filter performance, measuring staged efficiency, particle concentration, and emissions for research, quality control, and product certification purposes.

(3) What types of this product exist?

– The system can be configured with different modules: 2070 sensor (feed gas), 2300 sensor (purified gas), and RBG 1000 dust disperser, suitable for household, commercial, or industrial vacuum cleaners.

(4) What industry problems does it solve?

– Provides accurate staged efficiency data to ensure vacuum cleaners and filters meet EN 60312 and other international standards.

– Detects and analyzes multi-stage filtration performance to prevent leakage and optimize filter design.

– Supports R&D for new vacuum cleaners and HEPA filters, improving product competitiveness.

(5) How is it operated?

– Install the vacuum cleaner and dust disperser, start the test, measure feed and purified gas with 2070 and 2300 sensors, calculate staged separation efficiency via FTControl, and generate the test report.

Leave Message Get Price