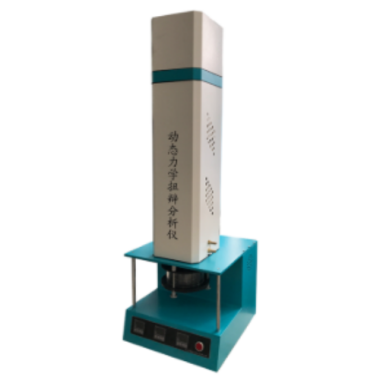

Dynamic mechanical torsional braid analyzer

The Dynamic Mechanical Torsional Braid Analyzer (TBA) is a computer-controlled thermomechanical analysis instrument used to characterize the viscoelastic properties of polymer materials through free-decay torsional vibration. Based on torsional braid analysis principles, the system measures dynamic modulus and mechanical loss as functions of temperature, stress, strain, and frequency. The instrument adopts digital measurement, automated control, and high-capacity data processing technology to replace traditional manual torsional braid testing, enabling accurate, sensitive, and repeatable evaluation of material viscoelastic behavior using minimal sample quantities.

Application

(1) Determination of dynamic modulus and mechanical loss of polymer materials under torsional vibration.

(2) Evaluation of viscoelastic behavior of polymers as a function of temperature.

(3) Characterization of glass transition behavior and relaxation processes in polymer systems.

(4) Comparative analysis of different polymer formulations and additives.

(5) Research on thermomechanical properties of elastomers, resins, fibers, and composite materials.

(6) Quality control testing for polymer raw materials and finished products.

(7) Material research and development in academic, industrial, and inspection laboratories.

Standards

(1) HST-BW-500 — Torsional Braid Analysis Method

(2) SN/T 3238.2-2012 — Test Method for Dynamic Mechanical Properties of Polymer Materials by Torsional Braid Analysis

Features

(1) Free-decay torsional vibration testing principle with high sensitivity.

(2) Minimal sample requirement compared with other dynamic mechanical analysis methods.

(3) Wide temperature testing range suitable for low- and high-temperature material evaluation.

(4) Computer-controlled digital measurement and automated data acquisition.

(5) Real-time calculation and display of viscoelastic parameters.

(6) Integrated data storage and processing system reducing manual operation.

(7) Stable mechanical structure ensuring repeatable test results.

Parameters

| Item | Specification |

|---|---|

| Test temperature range | −120 ℃ to 500 ℃ |

| Constant heating rate | 2 ± 1 ℃/min |

| Time measurement range | 0.01–9999.99 s |

| Relative swing angle | 30°–60° |

| Measurement display parameters | θ, P, △, G′, 1/P² |

| Equipment dimensions (L × W × H) | 340 × 500 × 1100 mm |

| Packed dimensions | 450 × 600 × 1350 mm |

| Equipment weight | 33 kg |

| Packed weight | 55 kg |

| Power supply | AC 220 V |

Accessories

(1) Torsional braid fixture set.

(2) Temperature control and sensing components.

(3) Data acquisition and control software.

(4) Standard calibration and mounting tools.

Test Procedures

(1) Prepare the torsional braid specimen and install it in the test fixture.

(2) Set the test mode and parameters via the control software.

(3) Configure the temperature range and heating rate.

(4) Initiate the torsional vibration test and allow free-decay oscillation.

(5) Record dynamic modulus and damping parameters automatically.

(6) Complete the test and save or export the measured data and curves.

Leave Message Get Price