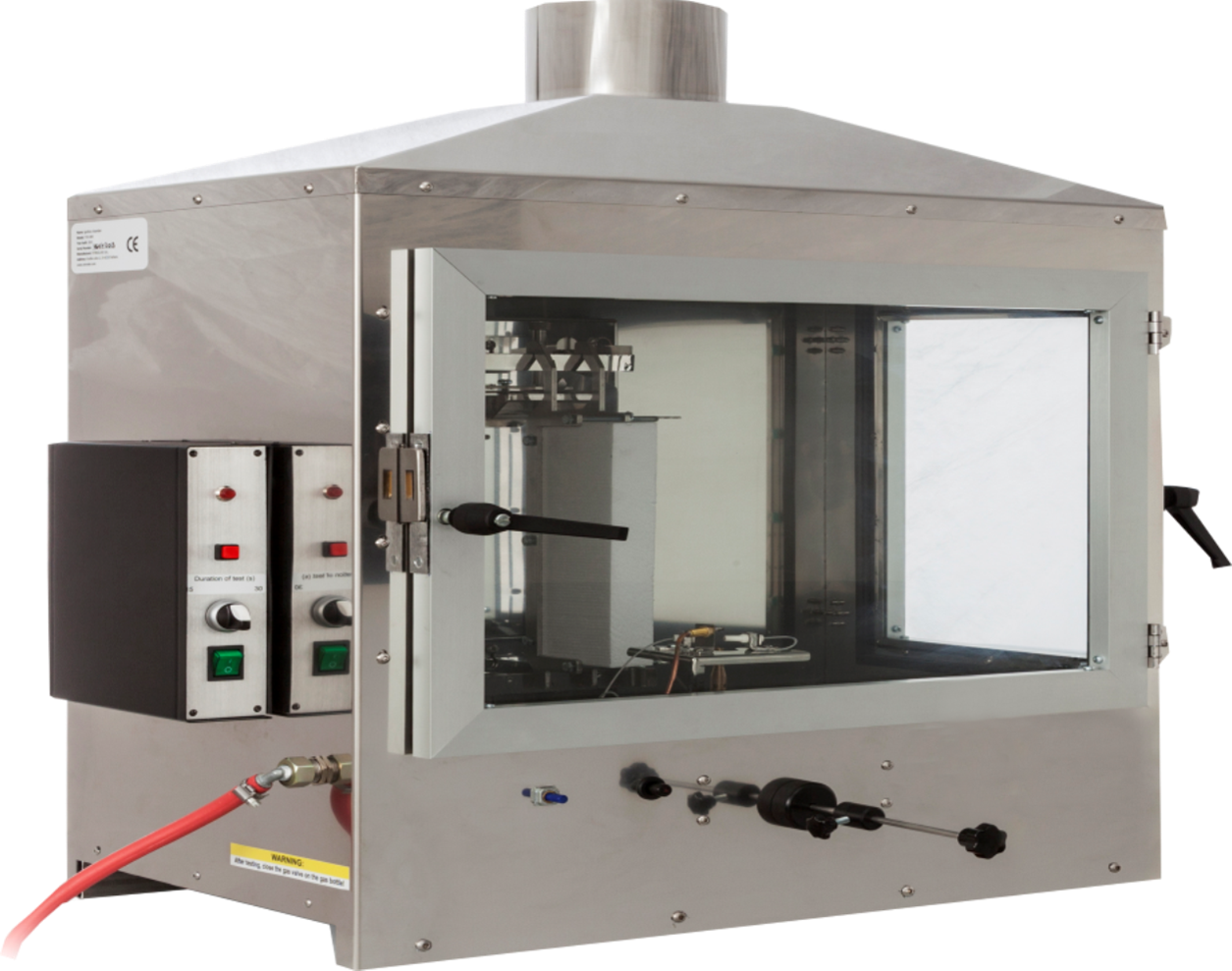

Combustibility Tester - EN ISO 11925-2

The Combustibility Tester is designed to evaluate the combustion behavior of building materials when exposed to a small direct flame in a vertical position, without external light sources. This testing is essential for fire safety engineering, allowing classification of building materials according to their flammability, and providing critical data to assess potential fire hazards in buildings.

The instrument is built in compliance with EN ISO 11925-2: Reaction to Fire Tests for Building Products — Part 2: Ignitability when Exposed to Direct Flame.

Applications

The Combustibility Tester is widely used for:

(1) Building Materials Fire Safety Assessment:

Evaluating walls, ceilings, floors, roofs, and other construction materials for combustibility.

Determining material reaction under flame exposure to support fire hazard classification.

(2) Construction Quality Control:

Routine testing for commercial and residential buildings to ensure materials meet fire safety standards.

Monitoring material consistency in production lines, prefabricated panels, and coatings.

(3) Research & Development:

Development of fire-retardant materials, coatings, and composite building materials.

Investigation of combustion behavior for innovative materials or improved flame retardancy.

(4) Regulatory Compliance:

Ensuring conformity with international fire safety standards for exports.

Supporting certification tests for EN ISO and local building fire codes.

(5) Education & Training:

Universities and technical colleges for fire engineering, safety engineering, and materials science experiments.

Laboratory demonstrations of vertical flame exposure effects on materials.

Standards

The tester complies with the following standards:

(1) EN ISO 11925-2:2010 — Reaction to Fire Tests for Building Products — Ignitability when Exposed to Direct Flame

(2) EN 13501-1 — Fire Classification of Construction Products and Building Elements

(3) ASTM E1354 — Cone Calorimeter Method for Determining Heat Release Rate

(4) ISO 5657 — Reaction-to-Fire Tests — Building Materials

(5) BS 476-20 — Fire Tests on Building Materials and Structures — Method for Determining the Fire Resistance

(6) NFPA 285 — Standard Fire Test Method for Evaluation of Fire Propagation Characteristics

(7) GB/T 8627-2012 — Classification for Combustibility of Building Materials (China)

Technical Parameters

| Item | Specification |

|---|---|

| Gas Type | Propane or Propane-Butane Mixture |

| Nozzle Diameter | 0.2 mm |

| Gas Pressure | 50 mbar |

| Test Chamber Internal Width | 700 mm |

| Test Chamber Internal Height | 400 mm |

| Overall Dimensions (L×W×H) | 700 × 400 × 900 mm |

| Weight | 48 kg |

| Construction | Full stainless steel structure; observation doors with tempered glass (front and side); stainless steel sample clamps and templates |

Features

(1) High Durability: Full stainless steel construction ensures corrosion resistance, stability, and long service life.

(2) Easy Observation: Front and side tempered glass doors allow full visual monitoring during tests.

(3) Safe Gas Control: Connected propane or propane-butane gas system with safety valves; flame intensity controlled via electronic regulators.

(4) Versatile Testing: Applicable to a wide range of building materials, including walls, floors, ceilings, and roofing panels.

(5) User-Friendly Operation: Simple interface with easy sample installation and automated flame control.

FAQ

(1) What is this product?

It is a laboratory instrument for testing the combustibility of building materials under direct flame in a vertical orientation.

(2) What is it used for?

To classify building materials based on their reaction to fire and support fire safety assessment.

(3) What types of materials can it test?

Walls, floors, ceilings, roofing materials, panels, coatings, and other construction materials.

(4) Why is it important?

Fire safety regulations require materials to be tested for combustibility; this helps reduce fire risks in buildings and ensures compliance with international standards.

(5) How does it operate?

Samples are mounted in a vertical position and exposed to a small direct flame from the nozzle; the flame behavior and combustibility are observed and recorded.

Leave Message Get Price