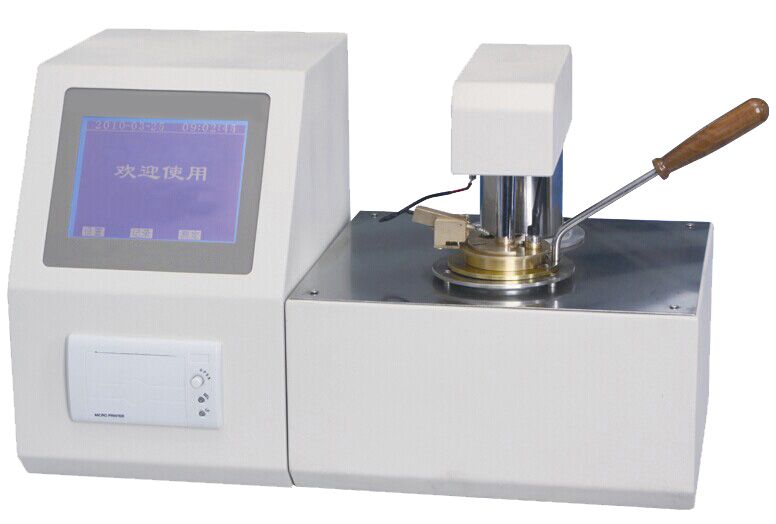

Open Cup Flash Point Tester — ISO 2592/ASTM D92

The Open Cup Flash Point Tester is designed to automatically determine the flash point and fire point of petroleum products (excluding crude oil and petroleum fuels) with fire points above 80 °C. By combining automated control with a user-friendly interface, the instrument enables precise, repeatable testing and allows comparison with manual test results. This tester is widely used in quality control, research, and safety verification in petrochemical and industrial laboratories.

Applications

This instrument is suitable for testing the flash and fire points of:

Gasoline, kerosene, diesel, and other refined petroleum products

Lubricating oils

Fuel oils and blended petroleum products

Industrial petroleum-based chemicals

Laboratory quality control of petroleum products

Safety evaluation in production, transport, and storage

Standards

(1) ISO 2592:2017 — Determination of Flash and Fire Points — Open Cup Method

(2) ASTM D92 — Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester

(3) IP 36 / IP 170 — Flash Point by Open Cup Method

(4) EN ISO 2592 — Petroleum products — Determination of Flash and Fire Point (Open Cup)

Technical Parameters

| Item | Description |

|---|---|

| Test Range | 80 °C to 400 °C |

| Test Modes | Fire Point & Flash Point / Flash Point / Special (Fast Search) |

| Display & Control | 5.5” touch screen |

| Temperature Sensor | K-type thermocouple with stainless steel sheath |

| Flash Detector | CdS (cadmium sulfide) photoresistor |

| Heating Method | Plate heater, 800 W, 220 V |

| Ignition Source | DC 24 V electric igniter |

| Cooling | Compressed air + multi-blade fan |

| Pressure Correction | Built-in barometer with software correction for standard atmospheric pressure |

| Preheat/Precool | Automatic preheat to desired flash point temperature |

| Test Environment | Room temperature 0–40 °C, RH <90 % |

| Instrument Dimensions | 550 × 400 × 320 mm |

| Workbench Dimensions | 1,000 × 600 × 800 mm |

| Power Supply | AC 220 V, 50/60 Hz, 15 A |

| Weight | 30 kg |

| Exhaust Requirement | ≥50 L/s |

| Calibration | Temperature: 12 points; Pressure: 2 points |

| Data Storage | Up to 20 test results automatically saved |

| Optional Accessories | Propane gas, dust collector |

Features

Fully automatic flash point and fire point testing with programmable heating and ignition

Automatic flash point search during heating with adjustable flame detection

Built-in air pressure correction for results standardized to atmospheric pressure

Durable DC 24 V electric igniter ensures consistent flame

Touchscreen interface with solvent-resistant protective foil

Calibration at multiple points for accurate results

Data management stores up to 20 historical tests for easy retrieval

Preheat and precool functions reduce waiting times between tests

Compact and robust design with integrated exhaust system

Rapid cooling using compressed air and multi-blade fan

FAQ

(1) What is this product?

It is an automated open cup tester for measuring flash and fire points of petroleum products.

(2) What is it used for?

To evaluate the flammability and fire safety of petroleum-based liquids.

(3) Why is it important?

Flash point determination ensures safe handling, storage, and transportation of petroleum products.

(4) What products can it test?

Refined fuels, lubricating oils, petroleum chemicals, and other flammable liquids.

(5) What types are there?

Automatic open cup testers, manual open cup testers, and hybrid models with both manual and automatic functions.

(6) How does it operate?

The sample is heated in a plate heater, the flash point is detected automatically by a CdS sensor, and the system records results, applies pressure corrections, and displays the temperature curve in real-time.

Leave Message Get Price