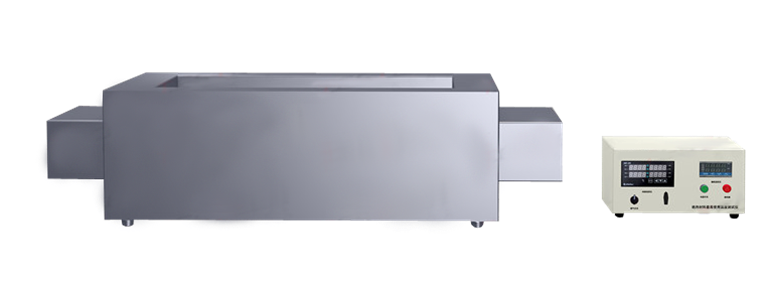

Insulation Material Maximum Use Temperature Tester

The Maximum Service Temperature Tester for Thermal Insulation Materials is designed to evaluate the highest allowable service temperature of insulation products under controlled laboratory conditions. By applying a defined thermal load and monitoring material performance changes, the instrument determines whether an insulation material can maintain its functional properties during use or after exposure to high temperatures. This evaluation is critical for product design, quality control, and safety verification of insulation materials used in industrial, construction, and energy applications.

Applications

The tester is suitable for evaluating the maximum service temperature of a wide range of thermal insulation products, including:

Loose-fill thermal insulation materials

Mineral wool mats and blankets

Insulation felts and quilts

Rigid insulation blocks and boards

Preformed insulation pipe sections

Prefabricated mineral wool pipe shells

High-temperature insulation panels for industrial furnaces

Insulation materials for HVAC systems

Thermal insulation used in power plants and petrochemical facilities

Standards

(1) GB/T 17430-1998 — Evaluation Method for Maximum Service Temperature of Thermal Insulation Materials

(2) ASTM C411-82 — Standard Test Method for Hot-Surface Performance of High-Temperature Thermal Insulation

(3) ASTM C447-85 — Standard Practice for Estimating the Maximum Use Temperature of Thermal Insulation Materials

(4) ISO 8142:1990 Annex A — Thermal Insulation — Determination of Maximum Service Temperature of Preformed Mineral Wool Pipe Sections

Technical Parameters

| Item | Description |

|---|---|

| Heating Power | 6 kW |

| Heating Plate Material | Stainless steel + silicon carbide |

| Heating Plate Test Area | 900 × 450 mm |

| Edge Protection Width | 80 mm |

| Heating Tube Material | SUS304 stainless steel |

| Heating Tube Length | 2000 mm |

| Heating Tube Diameter | 88 mm |

| Temperature Sensor Type | K-type thermocouples |

| Thermocouple Wire Diameter | 0.40 mm |

| Temperature Measurement Range | 0 – 1100 °C |

| Temperature Accuracy | ±0.5% |

| Temperature Uniformity | ≤5% or ≤15 °C between thermocouples |

| Thermocouple Arrangement | Center and diagonal positions, 150 mm from corners |

| Temperature Acquisition | PLC + temperature modules |

| Control System | PLC + touch screen |

| Data Processing | Automatic data storage and report output |

| Display | Real-time hot-face temperature curve |

| Auxiliary Tools | 1 m straightedge, feeler gauges (0.03 mm, 0.05 mm) |

| Software | Dedicated testing software |

| Computer & Printer | Included |

Features

(1) Stainless steel and silicon carbide heating plate with large effective test area

(2) SUS304 stainless steel heating tubes suitable for high-temperature operation

(3) K-type thermocouples with wide temperature range and high measurement accuracy

(4) Multiple thermocouple layout ensuring reliable temperature uniformity assessment

(5) PLC-based temperature acquisition with modular expansion

(6) Touch screen and computer control with real-time temperature curve display

(7) Automatic data storage and report generation

(8) Supplied with straightedge and precision feeler gauges for deformation evaluation

(9) Integrated testing software for standardized operation

FAQ

(1) What is this product?

It is a laboratory testing instrument used to determine the maximum service temperature of thermal insulation materials.

(2) What is it used for?

It is used to evaluate whether insulation materials maintain acceptable performance when exposed to elevated temperatures.

(3) Why is it important?

Determining the maximum service temperature is essential for material safety, durability, and compliance with international insulation standards.

(4) What products can it test?

Loose-fill insulation, mineral wool mats and blankets, insulation boards, blocks, felts, and preformed insulation pipe sections.

(5) What types are there?

The system supports multiple international standards and can be configured for different insulation forms and temperature requirements.

(6) How does it operate?

The specimen is placed on the heating surface, heated to a specified temperature profile, and monitored via thermocouples while the system automatically records and evaluates temperature and performance data.

Leave Message Get Price