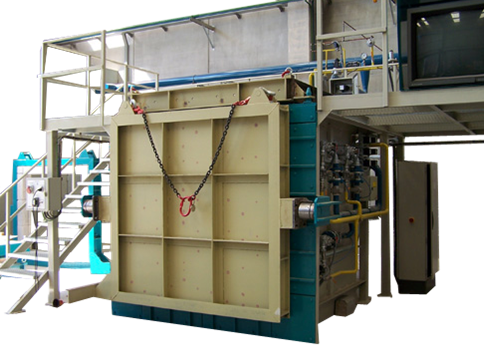

Vertical Fire Resistance Furnace for Building Components

The Vertical Fire Resistance Furnace for Building Components is designed to evaluate the fire resistance performance of construction elements exposed to standardized fire conditions in a vertical orientation. It provides critical data on the behavior of materials and assemblies under high-temperature exposure, including load-bearing capacity, flame integrity, and heat transmission. Compliant with EN 1363-1, EN 1363-2 hydrocarbon curve, and ISO 834 requirements, this furnace offers a reliable and accurate method for assessing fire resistance of building components under controlled time, temperature, and pressure conditions, supporting regulatory compliance, safety assessment, and product development.

Applications

The furnace is used for vertical fire resistance testing of a wide range of building components and assemblies, including but not limited to:

(1) Loadbearing and non-loadbearing wall assemblies (concrete, masonry, gypsum, composite walls)

(2) Fire doors, fire shutters, fire dampers, and fire-resistant door assemblies

(3) Curtain wall systems and façade components

(4) Service penetrations, penetration seals, and fire-stopping systems

(5) Structural connections and joint systems

(6) Insulated wall panels and sandwich panels

(7) Building service enclosures and shaft walls

(8) Custom assemblies requiring vertical fire exposure under standard or hydrocarbon fire curves

Standards

(1) EN 1363-1 — Fire resistance tests — Part 1: General requirements

(2) EN 1363-2 — Fire resistance tests — Part 2: Alternative and additional procedures (hydrocarbon curve)

(3) ISO 834 — Fire-resistance tests — Elements of building construction

(4) BS 476-20 — Fire tests on building materials and structures — Method for determination of the fire resistance of elements of construction (general principles)

(5) BS 476-21 — Fire resistance of loadbearing elements

(6) BS 476-22 — Fire resistance of non-loadbearing elements

(7) BS 476-23 — Fire resistance of components

(8) BS 476-24 — Fire resistance of ventilation ducts

(9) IMO FTP Code — Fire Test Procedures (hydrocarbon fire curve)

Technical Parameters

| Parameter | Specification |

|---|---|

| Internal Furnace Dimensions (W × H × D) | 3000 mm × 3000 mm × 1300 mm |

| Maximum Test Temperature | Up to 1250 °C |

| Burner Quantity | 12 luminous soft-flame LPG burners |

| Burner Arrangement | 6 burners on each side wall |

| Fuel Type | Liquefied Petroleum Gas (LPG) |

| Observation Ports | 4, quartz heat-resistant glass |

| Thermocouples | 9 × Type K + 1 plate thermocouple |

| Pressure Measurement Points | 4 (nickel alloy tubes with T-end) |

| Chimney Material | Low carbon steel, 9 mm thickness |

| Chimney Lining | High-temperature lining (first 6 m) |

| Data Acquisition Channels | 240 channels, bipolar differential |

| Input Range | 5 mV / 50 mV / 500 mV / 5000 mV DC (software programmable) |

| Resolution | 21-bit |

| Accuracy | 0.005% FS |

| Measurement Speed | 1 ms to 3 s (programmable) |

| Cold Junction Compensation | Absolute, ±0.1 °C |

| Computer Interface | RS-485 multi-drop, 75 Ω twisted pair |

| Power Supply | 200–240 VAC / 100–130 VAC / 24 VAC, 40–70 Hz |

| Power Consumption | 7 VA |

Features

(1) Furnace chamber lined with Grade 1400 insulating firebricks, refractory cast blocks, and slag boards

(2) Furnace roof constructed with shaped refractory bricks and in-situ refractory lining

(3) Use of diatomite insulation and ultra-low-temperature insulation materials in designated zones

(4) Dense 42% alumina refractory bricks applied in high-risk and cement-bonded areas

(5) Low-carbon steel furnace casing reinforced with C-channel and I-beams to minimize thermal deformation

(6) Custom vertical specimen fixing frames mounted on the furnace front with four door clamps

(7) Cold face insulated with inorganic fiber boards; hot face lined with refractory insulating bricks

(8) Four air-cooled quartz glass observation ports with sliding aluminum-fiber insulated shutters

(9) Twelve LPG luminous soft-flame burners with individual flame monitoring and safety systems

(10) Automatic and manual burner ignition according to preset temperature–time curves

(11) Three circular flue dampers with water-cooled shafts for furnace pressure control

(12) Dedicated chimney with refractory lining and configurable installation height

(13) Siemens PLC with remote I/O and fire test data management software

(14) Dual data recording system with real-time display and network sharing capability

(15) Fully independent manual operation mode with safety interlocks and audible alarms

FAQ

(1) What is this product?

It is a vertical fire resistance furnace designed to test the fire performance of building components under standardized fire exposure conditions.

(2) What is it used for?

It is used to evaluate fire resistance properties such as loadbearing capacity, integrity, insulation, and heat transfer of building elements.

(3) Why is it important?

It provides essential safety and compliance data required by building fire regulations and supports fire risk assessment and product certification.

(4) What products can it test?

Walls, fire doors, fire shutters, dampers, penetration seals, curtain walls, insulated panels, joints, and other vertical building assemblies.

(5) What types are there?

The furnace supports standard fire curves, hydrocarbon fire curves, and programmable custom temperature–time profiles.

(6) How does it operate?

Specimens are mounted in vertical frames and exposed to controlled fire conditions generated by LPG burners, with PLC-controlled temperature, pressure, and data acquisition throughout the test.

Leave Message Get Price