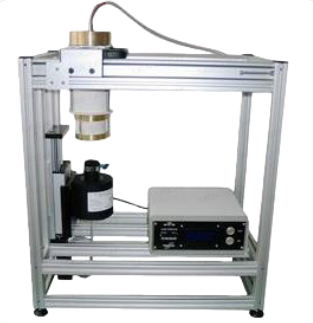

Contact Heat Transmission Tester ISO12127

The Contact Heat Transmission Tester for Protective Materials is designed to evaluate the thermal conduction performance of materials under contact heat conditions. The instrument measures heat transfer through protective fabrics or their components when subjected to a heated cylinder under a specified load. With precise data acquisition, simple operation, and high safety standards, this tester is widely used in protective clothing testing, particularly for fire-resistant and heat-protective garments.

Applications

The tester is suitable for assessing the heat transfer performance of materials, specifically:

(1) Protective clothing for firefighters and emergency personnel

(2) Heat-resistant and fireproof garment components

(3) Industrial protective clothing fabrics

(4) Laboratory and quality control testing of protective textiles

(5) R&D evaluation of new protective material composites

(6) Compliance testing for ISO and EN standards in protective equipment manufacturing

Standards

This instrument conforms to the following international standards:

(1) ISO 12127-2007 – Protective clothing – Protection against heat and fire – Determination of contact heat transmission through protective clothing or its materials

(2) EN 702 – Protective clothing – Protective against heat and fire – Test methods for the determination of heat transmission through protective clothing or materials

Technical Parameters

| Parameter | Specification |

|---|---|

| Thermocouple Type | K-type armored, Ø2 mm, accuracy ±0.1°C |

| Heated Cylinder Temperature | >500°C |

| Load Applied on Cylinder | 49 N, adjustable |

| Sample Contact Surface | Ø25.2 ±0.05 mm |

| Timing Range | 0–9999 s, accuracy 0.1 s |

| Calorimeter Plate | Ø25 mm, thickness 5 mm |

| Sample Holder | Nylon 66, Ø40 mm × 50 mm height |

| Sample Size | Ø80 mm |

| Test Bench Dimensions | 650 × 350 × 650 mm |

| Power Supply | 220V, 60 Hz, 800 W |

Features

(1) Instrument consists of a control box and stainless steel test frame for durability.

(2) Sample holder automatically moves up and down at 5 mm ±0.2 mm/s.

(3) Equipped with K-type armored thermocouples for precise temperature measurement.

(4) Heated cylinder with adjustable load for simulating real contact heat conditions.

(5) Built-in timer for accurate measurement of test duration.

(6) Calorimeter with platinum resistance temperature sensors for automated heat flux monitoring.

(7) PLC and touchscreen intelligent control system.

(8) PID intelligent temperature control with automatic data acquisition.

(9) Test results are automatically calculated, stored, and printable for records.

FAQ

(1) What is this product?

It is a tester designed to measure heat transfer through protective clothing materials.

(2) What is it used for?

It evaluates the thermal conduction of protective fabrics to determine their performance under contact heat conditions.

(3) Why is it important?

Accurate heat transmission data ensures protective clothing provides sufficient safety for firefighters and other personnel exposed to high temperatures.

(4) What products can it test?

Protective garments, fire-resistant fabrics, industrial safety clothing, and material composites used in thermal protective applications.

(5) What types are there?

Automatic or semi-automatic testers with adjustable cylinder temperature and load.

(6) How does it operate?

A heated cylinder applies contact heat to a sample under a specific load while thermocouples and calorimeters measure heat transfer. The system records, analyzes, and stores the data automatically.

Leave Message Get Price