Cascade Impactor

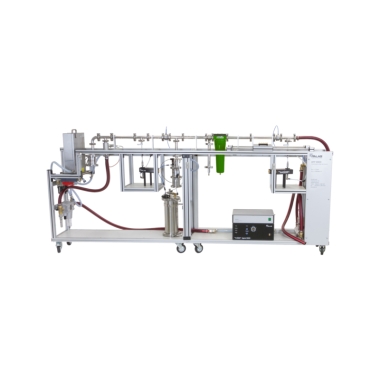

The cascade impactor is used for aerosol collection and size grading, it can collect nanoparticles (<100 nm) with uniform deposition characteristics. Thus, the microporous uniform deposition impactor (MOUDI TM) is developing. These precision cascade impactors are used to sample and collect the size graded samples for weight analysis and / or chemical analysis. Several models in the MOUDI ™ product line have a maximum flow rate of up to 30 L / min and a minimum cut size of 10 nm.

The MOUDI differs from other conventional cascade impacts. It uses a large number of micro-orifice nozzles to reduce injection speed and pressure drop, minimize particle bounce and re-entrain, and increase collection efficiency using up to 6,000 nozzles with diameter small to 50μm. Some models have a uniform deposition feature by rotating the nozzle-related impact plate so that the deposition of particles beneath the nozzle can be evenly distributed throughout the impact area.

Low flow model

2L / min miniature MOUDI impactor

The M135 Miniature MOUDI ™ Impactor is a precision high-precision impactor with a sample flow rate of 2.0L / min and a small size of 6, 8, 10 and 13 stages. The minimum particle size is 10nm. M135 6-stage and 8-stage impactors are used for personal selection, can replace the Marple Personal II impactor in the market.

Medium Velocity Type

8-stage object rotary type and rotary type MOUDI impactor 0.18-10μm

M100 is precision cascade impactors with sharp cut-size and low internal-loss characteristics. The M100 has 8 impaction stages and cut-size diameters from 0.18 µm to 18 µm. M100-NR is the object rotation type, M100-R is the rotary type. Impact stage rotation allows particle deposit on the impaction plate to spread out over a circular area to form a nearly uniform layer.

1. 30 L/min sampling flow rate.

2. 37mm or 47mm collecting substrates.

3. Micro-orifice nozzles to minimize pressure drop, particle bounce, and re-entrainment.

The MOUDI differs from other conventional cascade impacts. It uses a large number of micro-orifice nozzles to reduce injection speed and pressure drop, minimize particle bounce and re-entrain, and increase collection efficiency using up to 6,000 nozzles with diameter small to 50μm. Some models have a uniform deposition feature by rotating the nozzle-related impact plate so that the deposition of particles beneath the nozzle can be evenly distributed throughout the impact area.

Low flow model

2L / min miniature MOUDI impactor

The M135 Miniature MOUDI ™ Impactor is a precision high-precision impactor with a sample flow rate of 2.0L / min and a small size of 6, 8, 10 and 13 stages. The minimum particle size is 10nm. M135 6-stage and 8-stage impactors are used for personal selection, can replace the Marple Personal II impactor in the market.

| Type | Stage | Final-stage section cut size,μm | Head-stage section cut size, μm |

| M135-6 | 6 | 0.56 | 10 |

| M135-8 | 8 | 0.18 | 10 |

| M135-10 | 10 | 0.056 | 10 |

| M135-13 | 13 | 0.010 | 10 |

Medium Velocity Type

8-stage object rotary type and rotary type MOUDI impactor 0.18-10μm

M100 is precision cascade impactors with sharp cut-size and low internal-loss characteristics. The M100 has 8 impaction stages and cut-size diameters from 0.18 µm to 18 µm. M100-NR is the object rotation type, M100-R is the rotary type. Impact stage rotation allows particle deposit on the impaction plate to spread out over a circular area to form a nearly uniform layer.

1. 30 L/min sampling flow rate.

2. 37mm or 47mm collecting substrates.

3. Micro-orifice nozzles to minimize pressure drop, particle bounce, and re-entrainment.

Note:QINSUN is very in place for textile testing and quality control,we have our own textile testing lab. Our textile testing equipment and testing methods are in the leading position in the industry. We have passed the textile testing certification and iso textile testing standards issued by a number of testing,We can provide textile testing equipment pdf manual. Sufficient inventory, big discounts, limited time promotion, Order now!

Leave Message Get Price