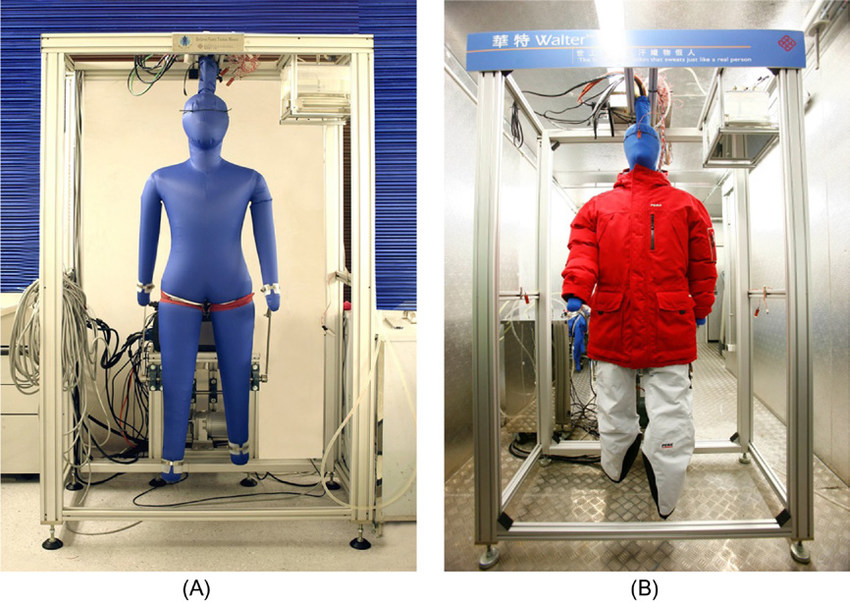

Sweating Thermal Manikin

Introduction

The sweating thermal manikin test system simulates the physical mechanism and heat exchange from the outside world. Obtain the thermal resistance, wet resistance and clo value of the material by the manikin monitoring results, and the influence of different clothing on the thermal comfort manikin is obtained by analyzing the software data.

Thermal manikin test system can characterize the impact of different clothing on human comfort performance by measuring the heat balance and the results of human comfort between heat generation of dressed manikin and the external environment. Then, guide the fabric and clothing development for the special using conditions of the comfort.

Thermal manikin test system with data analysis software present human sensory conclusions through the data. It avoids the real human test to achieve the uniform data results. Reduce the difference in results caused by differences in personal perception.

It is applicable to thermal insulation properties test of functional fabrics, clothing R & D and production, sleeping bags and other materials, It also can be used to analyze the environmental impact on human comfort and the environmental conditions that meet the comfort of the human body.

The United States, Canada, the United Kingdom, France, Germany, Russia, Switzerland, Sweden, Denmark, Finland, Norway, Hungary, Poland, Portugal, Japan, South Korea, Singapore and other countries have make this advanced technology apply to clothing, aerospace, fire, traffic safety and other fields. Especially in the hot and humid comfort evaluation and the development of occupational protective clothing. Thermal manikin can simulate the heat exchange process between human body, clothing and environment in the setting environment, scientifically evaluate the thermal performance of the whole clothing, avoid the influence of individual differences in human experiment with high experimental precision and good reproducibility. It has recognized as an indispensable means for the study of garment ergonomics.

Human body dissipates heat to the surrounding environment not only by the conduction, convection, radiation, but also by the body's skin sweat evaporation. If the water vapor can spread through the clothing system in time to the surrounding environment, we will feel comfortable. If the clothing hinders the passage of water vapor, increasing micro-climate humidity between the human skin and clothing, water vapor will accumulate to a certain extent and condensate into the water to make people feel uncomfortable. When the human body carry out intense activities or in a hot environment, the sweat evaporation is an important way to lose calories. Therefore, the clothes are asked to have high water vapor transmission capacity. Thus, it is necessary to accurately test the evaporation resistance of clothing in order to make a comprehensive evaluation of the heat and moisture transfer performance.

People have developed the sweating thermal manikin due to the dry thermal manikin only in the non-evaporative cooling range to simulate the physiological response of the human body. Early sweating thermal manikin simulate the human skin by covering its surface with a layer of cotton fabric or other moisture permeability underwear. Firstly, spray water to the simulated skin, then put on clothes to rise the temperature to a certain level. Every 5 minutes, the control system record the surface temperature, environmental parameters and heating power, and calculate the evaporation resistance of clothing. Finish this test before the simulation skin starting to dry. Since this process is a quasi-steady-state process, usually in a very short time, mainly by the operators’ subjective judgment the relatively stable evaporation resistance value as a test result, so can not use this method to accurately and repeatedly measure the evaporation of clothing resistance.

The new sweating Thermal manikin can solve above problems. Water circulation system distribute the water with a certain percentage to the whole body which heated by the central part of the trunk, to simulate the body's entire temperature distribution. The manikin’s skin is made of a material containing a microporous structure that evaporates the water vapor to simulate human sweating. By calculating the difference of manikin skin environment temperature and the skin and clothing outside humidity, and two indicators that the above two changes in the formation of thermal resistance and wet resistance. The latest sweating thermal manikin uses motor-driven its body to mimic human walking and achieve the goal of dynamic testing.

Features

1. Surface black treatment, perfectly simulate human skin with the same radiation.

2. Insulation capacity between the independent heating section achieves isothermal heating. It also achieve the human body temperature difference for the special test requirements. Temperature difference in the adjacent two sections up to 2 ℃. Maximum degree simulate the different parts of the body temperature difference.

3. Neck cable make clothing easy to wear off, without prejudice to wearing head protection devices, such as hats, masks, etc.

4. The manikin can stand, sit, walk and run. A variety of action modes meet different test and practical needs.

5. Controlled sweating system control sweating speed precisely, "sweat" preheat system minimizes the effect of temperature difference on test results.

6. Segmental sweating control system achieves different parts of sweat rates for the real simulation.

7. Constant temperature test, variable temperature test, constant power test, variable power test. 4 kinds of work modes.

8. ThermoTech control analysis software, real-time monitoring test situation, real-time display test results, provide data analysis, data storage and print output and other functions.

Technical Parameters

| Items | Parameters |

| Material | Antirust copper alloy material |

| Heating section | 32 section (other quantities need to be customized) |

| Temperature detection section | 32 section (other quantities need to be customized) |

| Temperature range | Indoor temperature-55℃ |

| Temperature control accuracy | ±0.1℃ |

| Temperature stability | ±0.1℃ |

| Heating output power | 800-1000W |

| Power accuracy | ≤1% |

| Height of manikin | 175cm(other height need to be customized) |

| Weight of manikin | ≤65kg |

| Heating component | Hot plate heat |

| Environment temperature monitor | 4 section |

| Environment humidity monitor | 2 section |

| Work modes | Constant temperature test, variable temperature test, constant power test, variable power test |

| Sweating system | Controlled, sweat preheating system |

| Walking speed | 0-100m/min |

| Running speed | ≤250m/min |

| Step | 0-100cm/step |

| Safety protection function | Anti-leakage safety protection device, overrun alarm, overheating automatic power off function |

| Test index | Thermal resistance results, Clo value and so on |

| Test software | ThermaoTech Control analysis software |

| Comfort evaluation module | Thermal comfort evaluation model and EQT evaluation model |

| Power | 220V, 50Hz |

| Dimension | 1200 mm(W)×1200mm(L)×2200mm (H) |

| Weight | 475kg |

Configuration

| Item No | Details |

| 5300201 | Thomas sweating thermal |

| 5300202 | Walking module |

| 5300203 | Thermal comfort analysis module |

| 5300204 | Walk-in constant temperature and humidity box |

| 5300205 | Pure water machine |

| 5300206 | Lenovo brand desktop computer, 1 set |

Leave Message Get Price