Dust Filter Efficiency Test System

Dust filter efficiency test system compares the different pulse clean filter characteristics according to VDI / DIN 3926, ASTM D6830-02, ISO 11057, GB / T 6719, GB12625 and other standards. At the same time through the laboratory results to understand the filter in the practical application. This instrument is suitable for various cleanable filter media under the dry environment with static and dynamic testing methods.

Test principle: Firstly, deliver the air into the vertical dust pipe to produce dusty dirty airflow. with the compressed air, the dust disperses in the dust generator, distributing the vertical pipeline when it forms the consistent concentration. These dusts flow down, and part of them get reach the horizontal pipe through the test filter media with the air flow. Exposing it to constant airflow and dust concentration to simulate the operation of the cleanable filter.

Dusts form a powder, resulting in increased pressure drop. Use differential pressure sensor to detect the real-time of the filter before and after the pressure drop changes. Once the pressure drop reaches the preset value, the system releases the clean compressed air pulse to the side of the dust powder which is produced by dirty gas except for the anti-blowing cleaning (online cleaning) by airflow. Then, the filter material re-filter dust, again and again. The cleaning pulses time must be accurate and reproducible to make the average and consistent pressure surface when it cross the filter media.

The removed powder and the residual dust fall off the dust collector at the bottom of the dirty air tube with the southerly airflow. The instrument is equipped with a dirty gas filter so that the dust will not be redistributed upstream the dirty gas of the filter media to cause the unspecified dust concentration with ineffective measurement (especially important parameters: residual pressure drop) . This design realizes error-free long-term operation to avoid the comprehensive interruption of measurement without cleanable dust deposition.

Test Items

· Output dust concentration.

· The increased weight of test filter media.

· Initial residual pressure drop. Average surplus.

· Pressure drop. The increment of residual pressure drop.

· Average filtration cycle.

Standards

1. ASTM D6830-02 Standard test method for characterizing the pressure drop and filtration performance of cleanable filter media

2. ISO 11057 Air quality - Test method for filtration characterization of cleanable filter media

3. VDI/DIN 3926 Testing of cleanable filter media. Standards test for the evaluation of cleanable filter media

4. GB/T6719 Specifications for bag house

5. GB 12625 Technical requirements of fabric and bag for bag filter.

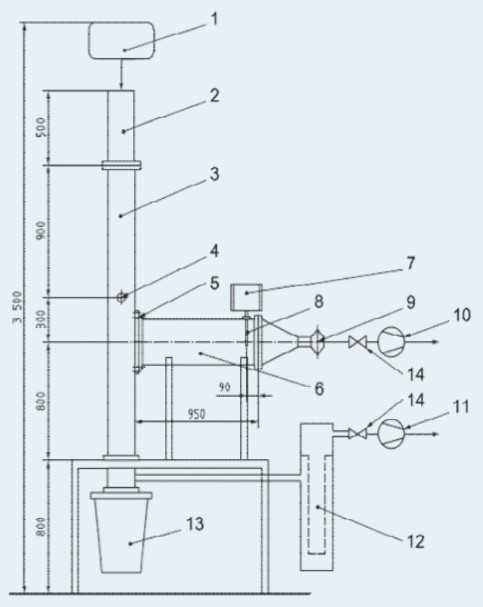

Instrument Structure

1. Aerosol generator. 2. Mixed pipeline.

3. Vertical dirty gas pipeline, transverse plane 120 × 300mm.

4. Optical concentration detector.

5. Filter holder, 140mm filter area.

6. Horizontal clean gas pipe, diameter 150mm.

7. Compressed gas cylinder (2.5L/0.5MPa).

8. Nozzle.

9. The absolute filter media uses to measure clean gas weight.

10. Clean gas suction (pump).

11. Vertical dirty air pipe suction (pump).

12. Dirty gas reserve filter.

13. Vertical pipe dust container.

14. Total flow controller.

Test principle: Firstly, deliver the air into the vertical dust pipe to produce dusty dirty airflow. with the compressed air, the dust disperses in the dust generator, distributing the vertical pipeline when it forms the consistent concentration. These dusts flow down, and part of them get reach the horizontal pipe through the test filter media with the air flow. Exposing it to constant airflow and dust concentration to simulate the operation of the cleanable filter.

Dusts form a powder, resulting in increased pressure drop. Use differential pressure sensor to detect the real-time of the filter before and after the pressure drop changes. Once the pressure drop reaches the preset value, the system releases the clean compressed air pulse to the side of the dust powder which is produced by dirty gas except for the anti-blowing cleaning (online cleaning) by airflow. Then, the filter material re-filter dust, again and again. The cleaning pulses time must be accurate and reproducible to make the average and consistent pressure surface when it cross the filter media.

The removed powder and the residual dust fall off the dust collector at the bottom of the dirty air tube with the southerly airflow. The instrument is equipped with a dirty gas filter so that the dust will not be redistributed upstream the dirty gas of the filter media to cause the unspecified dust concentration with ineffective measurement (especially important parameters: residual pressure drop) . This design realizes error-free long-term operation to avoid the comprehensive interruption of measurement without cleanable dust deposition.

Test Items

· Output dust concentration.

· The increased weight of test filter media.

· Initial residual pressure drop. Average surplus.

· Pressure drop. The increment of residual pressure drop.

· Average filtration cycle.

Standards

1. ASTM D6830-02 Standard test method for characterizing the pressure drop and filtration performance of cleanable filter media

2. ISO 11057 Air quality - Test method for filtration characterization of cleanable filter media

3. VDI/DIN 3926 Testing of cleanable filter media. Standards test for the evaluation of cleanable filter media

4. GB/T6719 Specifications for bag house

5. GB 12625 Technical requirements of fabric and bag for bag filter.

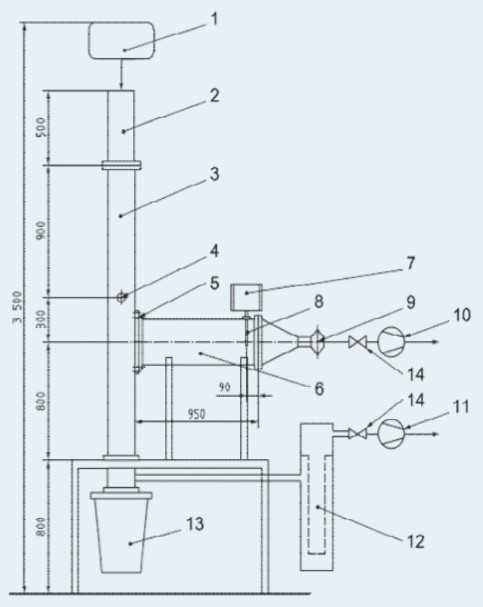

Instrument Structure

1. Aerosol generator. 2. Mixed pipeline.

3. Vertical dirty gas pipeline, transverse plane 120 × 300mm.

4. Optical concentration detector.

5. Filter holder, 140mm filter area.

6. Horizontal clean gas pipe, diameter 150mm.

7. Compressed gas cylinder (2.5L/0.5MPa).

8. Nozzle.

9. The absolute filter media uses to measure clean gas weight.

10. Clean gas suction (pump).

11. Vertical dirty air pipe suction (pump).

12. Dirty gas reserve filter.

13. Vertical pipe dust container.

14. Total flow controller.

Note:QINSUN is very in place for textile testing and quality control,we have our own textile testing lab. Our textile testing equipment and testing methods are in the leading position in the industry. We have passed the textile testing certification and iso textile testing standards issued by a number of testing,We can provide textile testing equipment pdf manual. Sufficient inventory, big discounts, limited time promotion, Order now!

Leave Message Get Price