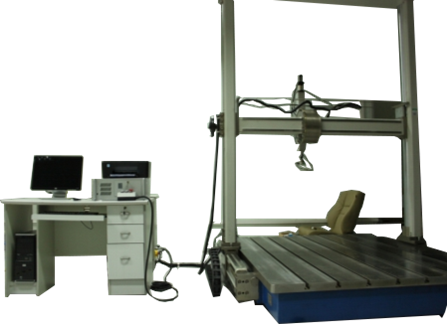

Seat Static Load Test Bench

The Seat Static Load Test Bench (hereinafter referred to as the "Test Bench") is designed to evaluate the comfort and static load performance of automotive seats. It provides accurate measurements under various static loading conditions, ensuring reliable assessment of seat durability and structural integrity. The system primarily complies with QC/T 740-2005 standard.

Application

The Test Bench is suitable for:

Automotive seat static load testing

Seat comfort evaluation

Seat component strength and deformation analysis

Testing of commercial, passenger, and specialty vehicle seats

Standards

QC/T 740-2005: Automotive Seat Static Load Test

ISO 5970: Road vehicles — Seat strength test methods

FMVSS 207: Seating systems in motor vehicles (USA)

GB/T 31487: Motor vehicle seat strength test methods

Parameters

| Item | Specification |

|---|---|

| Maximum Load | 10 kN |

| Load Measurement Accuracy | ±1% |

| Load Display Resolution | 0.05 N |

| Displacement Speed Range | 0.1–300 mm/min |

| Displacement Speed Accuracy | ±1.0% of indicated value |

| Load Movement Displacement Accuracy | ±0.5% FS |

| Load Movement Displacement Resolution | 0.0002 mm |

| X-Axis Adjustable Stroke | 1000 mm |

| Y-Axis Adjustable Stroke | 1500 mm |

| Z-Axis Crossbeam Stroke | 1400 mm |

| Electric Cylinder Stroke | 400 mm |

| Electric Cylinder Rotation Angle | ±90° |

| Power Supply | AC 220V, 50Hz, 3 kW |

Features

Full-range load capability without manual range switching.

Database storage of all test data; enables post-test analysis, curve overlay, automatic scaling, and multi-point data display.

Overlay of multiple test curves on the same coordinate system.

Adjustable loading angles for flexible test configurations.

Windows-based virtual instrument software; test curves displayed in simulated oscilloscope mode.

Test data exportable to Excel for comprehensive analysis and report generation.

Simple and user-friendly load and displacement calibration.

Analysis software can be installed on multiple PCs for collaborative data processing.

Modular measurement and control system design ensures easy maintenance.

Comprehensive safety features: limit protection, overload protection, software safety settings.

Accessories

Main Test Bench Frame

High-Precision Load Sensor

Displacement Sensor

X- and Y-Axis Travel Adjustment Motors

Panasonic Servo Motor with Gearbox

Force Direction Adjustment Device

Standard Operating Software and PC with Display & Printer

Test Procedures

Install the seat specimen securely on the test platform.

Adjust the X, Y, and Z travel settings according to the seat geometry.

Configure the load, displacement, and angle parameters in the control software.

Start the test; the electric cylinder applies load according to the pre-set program.

Monitor load and displacement values in real-time on the software interface.

Upon completion, the system automatically stops, and results can be reviewed or exported.

Maintenance Information

Regularly check and calibrate the load sensor and displacement sensor.

Keep guide rails, lead screws, and moving components clean and lubricated.

Inspect electric cylinders and servo motors for smooth operation.

Periodically check electrical connections and software functionality.

Shut down and disconnect power when not in use to extend equipment lifespan.

FAQ

What is this product?

It is a seat static load test bench for evaluating seat comfort and structural performance under static loads.

What is it used for?

It is used to measure seat load capacity, displacement, and deformation, and to assess seat comfort and durability.

Why is it important?

It ensures seat safety, durability, and comfort, providing critical data for automotive manufacturers.

Which industries is it suitable for?

Automotive, commercial vehicle, and specialty vehicle seat manufacturers and testing centers.

What types are available?

Variants include single-axis or multi-axis adjustable benches, with different load capacities up to 10 kN.

Leave Message Get Price