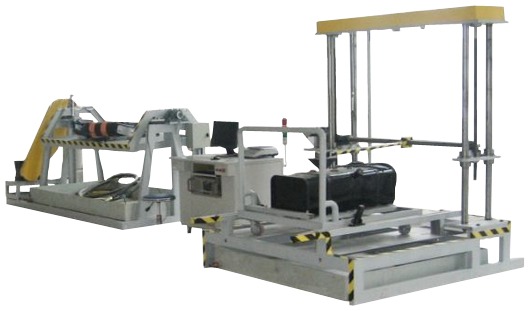

Fuel Tank Performance and Durability Test Bench

The Fuel Tank Performance and Durability Test Bench is designed to evaluate the safety and performance of automotive fuel tanks, including both metal and plastic types. It allows testing under various operational and environmental conditions to ensure compliance with safety standards and durability requirements.

Application

The test bench is applicable for:

(1) Testing metal and plastic fuel tanks for automobiles.

(2) Evaluating fuel tank performance indicators such as sealing, pressure resistance, impact resistance, and fire resistance.

(3) Verification of safety valve and vent valve functionality.

(4) Compliance testing for gasoline and diesel fuel tanks of different shapes and capacities.

Standards

The Fuel Tank Test Bench meets the following standards:

(1) GB/T 18296-2001 – Safety performance requirements and test methods for automotive fuel tanks

(2) QC/T 644-2000 – Technical specifications for automotive metal fuel tanks

(3) ISO 3833 – Road vehicles – Vocabulary of fuel system components (for reference)

(4) OEM-specific requirements for fuel tank safety and durability

Test Items

Plastic Fuel Tanks:

(1) Sealing performance test

(2) Low-temperature impact resistance

(3) Safety valve opening pressure

(4) Vent valve opening pressure

(5) Corner hammer impact resistance

(6) Pressure resistance

(7) Fire resistance

Metal Fuel Tanks:

(1) Safety valve opening pressure

(2) Vent valve opening pressure

(3) Pressure resistance

Test Bench Structure

(1) The test bench consists of:

Water tank

Water supply and drainage system

Drive unit

Corner hammer impact testing device

Control cabinet

(2) The structure is mainly steel, with components connected via aviation joints and cables.

(3) The layout is compact and well-organized, with corrosion-resistant and oil-resistant materials; key components are made of stainless steel.

(4) The test bench is equipped with brakeable wheels for mobility, allowing testing at different locations.

(5) Overall design is robust, visually appealing, and user-friendly.

Features

(1) Supports testing of both metal and plastic automotive fuel tanks.

(2) Compact and integrated steel frame design.

(3) Corrosion, water, and oil-resistant construction for durability.

(4) Movable base with brakeable wheels for flexible operation.

(5) Compatible with various test standards and customized customer requirements.

(6) Easy operation and maintenance with intuitive control cabinet interface.

Technical Parameters

| Item | Specification |

|---|---|

| Test tank type | Metal and plastic automotive fuel tanks |

| Test media | Gasoline, Diesel (for reference, actual testing per standard) |

| Safety valve testing | Up to standard-specified pressure |

| Vent valve testing | Up to standard-specified pressure |

| Low-temperature impact | As per standard GB/T 18296-2001 |

| Corner hammer impact | As per standard GB/T 18296-2001 |

| Pressure resistance | As per standard GB/T 18296-2001 |

| Fire resistance | As per standard GB/T 18296-2001 |

| Power supply | AC 220V / 50Hz or AC 380V / 50Hz (depending on configuration) |

| Mobility | Brakeable rolling wheels installed |

| Material | Steel frame, stainless steel key components |

| Overall dimension | Customized based on configuration |

| Weight | Customized based on configuration |

FAQ

1. Can the bench test both plastic and metal fuel tanks?

Yes, the system supports both types with relevant test modules.

2. How is mobility achieved?

The bench is equipped with brakeable rolling wheels, enabling testing at different locations.

3. Can the bench simulate fire resistance tests?

Yes, the system allows controlled fire-resistance testing in accordance with GB/T 18296-2001.

4. Are safety valve and vent valve pressures adjustable?

Yes, test pressure settings follow standard-specified limits.

5. Is the bench resistant to water, oil, and corrosion?

Yes, all components are corrosion- and oil-resistant, with key parts made of stainless stee

Leave Message Get Price