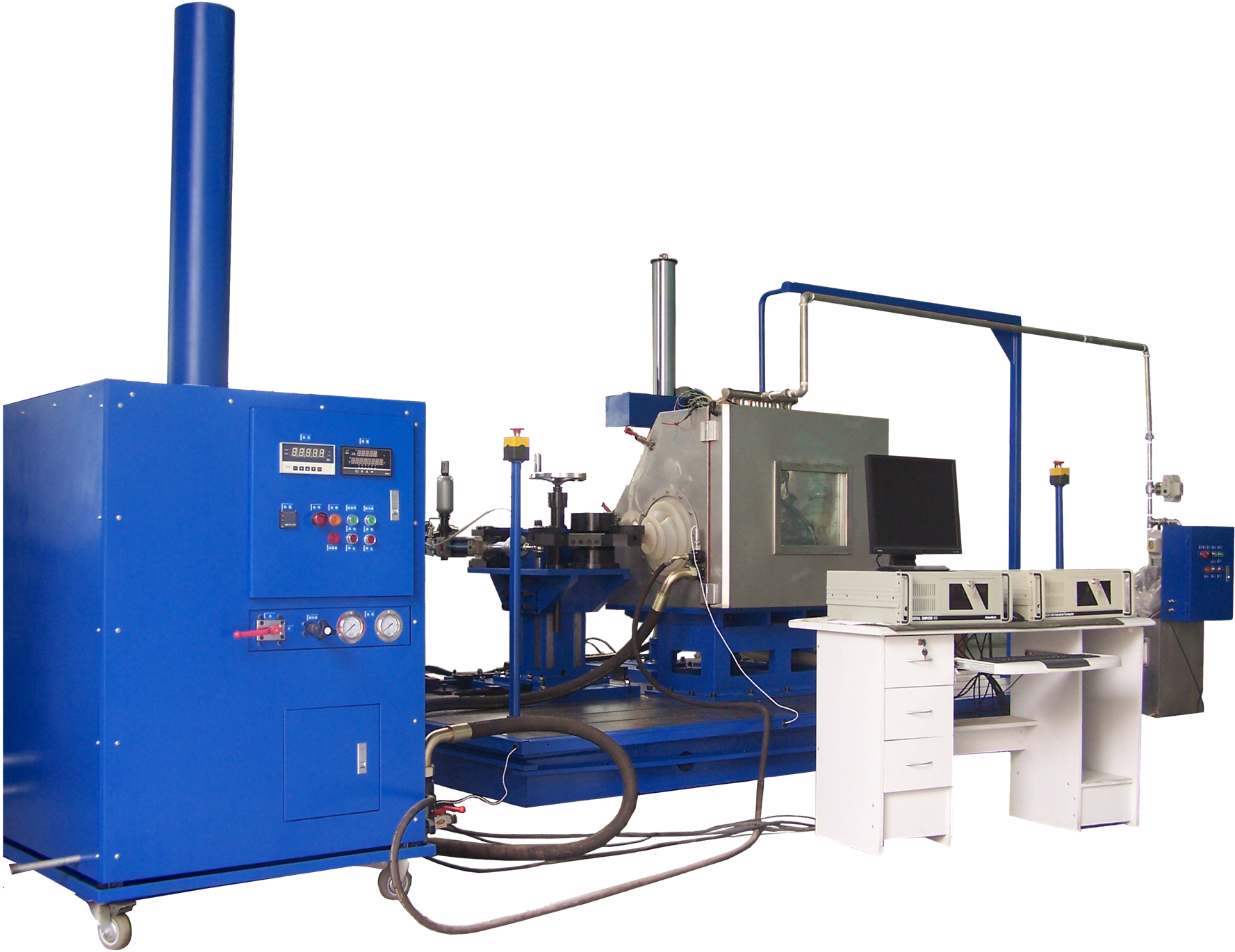

Steering Gear Fatigue Test Bench

The Steering Gear Environmental Fatigue Test Bench is designed to simulate the operational conditions of automotive steering gear assemblies under laboratory environments, including torque input, load, and environmental conditions. The system enables continuous high-load operation under specific conditions, allowing accelerated evaluation of the durability of the steering gear assembly and its components.

Application

The test bench is applicable for:

(1) Durability evaluation of complete steering gear assemblies.

(2) Assessment of individual steering gear components under high-load and controlled environmental conditions.

(3) Accelerated fatigue testing in automotive research and development.

(4) Verification of steering gear performance under extreme environmental conditions.

Standards

The Steering Gear Environmental Fatigue Test Bench meets or references the following standards:

(1) ISO 6621 – Hydraulic steering systems – Endurance testing

(2) ISO 10789 – Steering systems – Mechanical performance testing

(3) GB/T 13948 – Road vehicle steering gear – Fatigue and environmental testing

(4) SAE J670 – Steering gear – Environmental and fatigue testing

(5) OEM-specific standards from automotive manufacturers (e.g., VW, GM, Nissan, Ford)

Technical Parameters

| Item | Specification |

|---|---|

| Load range | ±15 kN |

| Displacement range | ±125 mm |

| Torque range | ±100 Nm |

| Torsion angle | ±1000° |

| Control modes | Displacement, Load, Torque, Torsion Angle |

| Displacement amplifier accuracy | Full-scale ±1% (100%, 50%, 20% ranges; bidirectional) |

| Load amplifier accuracy | ±1% of reading (100%, 50%, 20% ranges; bidirectional) |

| Torsion angle amplifier accuracy | ±1% of reading (100%, 50%, 20% ranges; bidirectional) |

| Torque amplifier accuracy | ±1% of reading (100%, 50%, 20% ranges; bidirectional) |

| Test frequency range | 0.01 – 25 Hz |

| Test count range | 0 – 99,999,999 |

| Test waveforms | Sine, Triangle, Square, Sawtooth, Composite waveforms |

| Safety protection | Overload, Limit, Fracture protection |

| Temperature range | -60°C to +150°C |

| Temperature fluctuation | ±0.5°C |

| Temperature uniformity | ±3°C |

| Temperature ramp rate | 2°C/min |

| Spray flow rate | 10 L/min |

| Power supply | AC 380V, 50 Hz, 15 kW |

Features

(1) Multi-mode control including displacement, load, torque, and torsion angle.

(2) Independent amplifiers for precise measurement of displacement, load, torque, and angle.

(3) Supports various waveform testing for comprehensive fatigue evaluation.

(4) Wide temperature range with accurate control and uniformity.

(5) Integrated environmental simulation including temperature and spray systems.

(6) Safety protections including overload, limit, and fracture detection.

(7) Test data acquisition and storage for post-test analysis.

(8) Suitable for both complete steering gear assemblies and individual components.

Accessories

(1) Main test bench frame with steering gear mounting fixture

(2) Torque and torsion measurement modules

(3) Displacement and load amplifiers

(4) Environmental chamber with temperature and spray system

(5) Control cabinet with industrial PC and software

(6) Safety interlocks and limit switches

Test Procedure

(1) Mount the steering gear assembly or component onto the test bench fixture.

(2) Configure environmental parameters (temperature, spray, load, torque, displacement).

(3) Select the desired waveform (sine, triangle, square, sawtooth, or composite).

(4) Set test frequency and number of cycles.

(5) Start the test; the system applies torque, load, and environmental conditions automatically.

(6) Monitor real-time load, torque, displacement, and torsion angle data.

(7) System automatically stops at the end of cycles or upon detecting overload or failure.

(8) Post-test data analysis and report generation.

FAQ

1. What types of steering gear components can be tested?

Complete assemblies, racks, pinions, steering shafts, and related components.

2. Can the system simulate extreme temperatures?

Yes. Operating range is -60°C to +150°C with ±0.5°C fluctuation.

3. What waveform options are available for fatigue testing?

Sine, triangle, square, sawtooth, and composite waveforms.

4. How is safety ensured during high-load testing?

The system includes overload, limit, and fracture protections, with automatic shutdown.

5. Is test data exportable for analysis?

Yes. Data can be exported for post-test analysis and report generation.

Leave Message Get Price