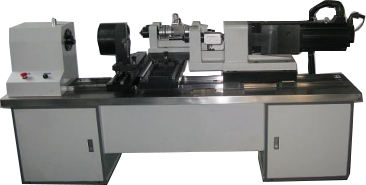

Thread Friction Coefficient Test Instrument

The Computer-Controlled Thread Friction Coefficient Test Bench is designed for mechanical performance testing of threaded fasteners such as carbon steel and alloy steel bolts, screws, and studs. The system is used to evaluate effective tightening torque, clamping force, and friction coefficients during tightening processes. It is suitable for product development, process changes, material changes, supplier qualification, incoming inspection, and routine quality sampling tests.

The test software operates in a Windows-based virtual instrument environment, providing a user-friendly interface and convenient operation.

Application

The test bench is applicable to friction and tightening performance testing of the following specific products:

(1) Hexagon bolts made of carbon steel and alloy steel

(2) Screws and threaded studs

(3) Locking nuts and structural nuts

(4) Automotive threaded fasteners

(5) High-strength fasteners for mechanical assemblies

(6) Threaded fasteners used in quality verification and supplier assessment

Standards

The Thread Friction Coefficient Test Bench complies with the following standards:

(1) GB/T 16823.3-1997 – Threaded Fasteners – Tightening Test Methods

(2) QC/T 715-2004 – Test Method for Friction Coefficient of Threaded Joints for Automobiles

(3) GB/T 3098.9-2002 – Mechanical Properties of Fasteners – Prevailing Torque Type Steel Hexagon Nuts

(4) ISO 16047 – Fasteners – Torque/Clamping Force Testing

(5) ISO 898-2 – Mechanical Properties of Fasteners – Nuts

(6) SAE J995 – Mechanical and Material Requirements for Steel Nuts

(7) OEM-specific fastener tightening and friction test specifications

Parameters

| Item | Specification |

|---|---|

| Dynamic torque range | 10 – 500 Nm |

| Static torque range | 5 – 100 Nm |

| Torque measurement accuracy | ±1% |

| Angular resolution | 0.025° |

| Angular measurement accuracy | ±0.5% FS |

| Drive chuck speed | 1 – 50 r/min |

| Maximum clamping load | 300 kN |

| Clamping load test range | 10 – 300 kN |

| Clamping load accuracy | ±1% |

| Torsion direction | Clockwise / Counterclockwise |

| Thread size range | M6 – M12 (Grade 6 – 12) |

| Main machine dimensions | 2000 × 450 × 1100 mm |

| Electrical control cabinet | 400 × 400 × 600 mm |

| Computer control cabinet | 600 × 800 × 1800 mm |

| Power supply | AC 220 V, 50 Hz, 1 kW / AC 380 V, 50 Hz, 5 kW |

Features

(1) Full-range torque and load measurement without range segmentation.

(2) Database-based storage of all test data for traceability and analysis.

(3) Post-test data analysis including automatic scaling and point-by-point data display.

(4) Virtual instrument interface with oscilloscope-style real-time display of torque, angle, and test curves.

(5) Arbitrary setting and automatic holding of target tightening angle.

(6) Arbitrary setting and automatic holding of target clamping force.

(7) Maximum and minimum torque peak hold functions.

(8) Automatic generation of clamping force–torque curves and angle–torque curves.

(9) Input of bolt diameter for automatic calculation of mechanical performance parameters and generation of complete test reports.

(10) Calculation of thread friction coefficient, bearing surface friction coefficient, and effective tightening torque.

(11) Simple and convenient calibration of torque, angle, and load sensors.

(12) Modular measurement and control system design for easy maintenance.

(13) Overload protection and software-defined safety limits.

Accessories

(1) Test base and linear guide assembly

(2) Static torque loading unit

(3) Dynamic torque loading unit (100 Nm)

(4) Dynamic torque loading unit (500 Nm)

(5) Load application device

(6) Electric motor and reducer

(7) Electrical control cabinet

(8) Industrial computer, display, and printer

Test Procedures

(1) Install the threaded fastener specimen and select the appropriate fixture.

(2) Input fastener specifications such as diameter and grade into the control software.

(3) Set test parameters including torque mode, target clamping force, rotation speed, and test direction.

(4) Start the test and perform the tightening process automatically.

(5) Monitor real-time torque, angle, and clamping force curves.

(6) Complete the test and automatically calculate friction coefficients and effective torque.

(7) Store data and generate the test report.

Maintenance Information

(1) Periodically calibrate torque, angle, and load sensors.

(2) Inspect fixtures and drive components for wear or looseness.

(3) Maintain cleanliness of the guide rails and moving parts.

(4) Check electrical wiring and grounding regularly.

(5) Back up test data and verify software operation periodically.

FAQ

1. What parameters can this test bench measure?

Torque, tightening angle, clamping force, thread friction coefficient, bearing surface friction coefficient, and effective tightening torque.

2. What fastener sizes are supported?

Standard configuration supports M6 to M12 threaded fasteners.

3. Can both static and dynamic torque tests be performed?

Yes. The system supports both static torque and dynamic tightening torque testing.

4. Is test report generation automatic?

Yes. Complete test reports can be generated and printed automatically after testing.

5. Who typically uses this equipment?

Fastener manufacturers, automotive OEMs, component suppliers, and third-party testing laboratories.

Leave Message Get Price