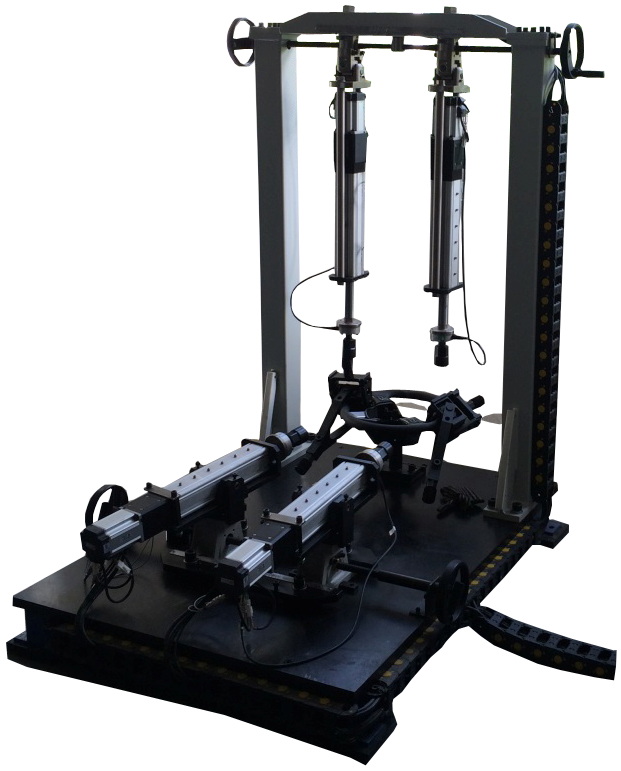

Steering Wheel Integrated Fatigue Durability Test Bench

The Steering Wheel Integrated Fatigue Durability Test Bench is designed for conducting integrated bending and torsional fatigue durability tests, as well as bending fatigue durability tests, on automotive steering wheels. The system applies alternating or sinusoidal loads to simulate real service conditions and evaluate the structural durability and fatigue resistance of steering wheels under long-term cyclic loading.

Application

The test bench is applicable to fatigue durability testing of the following specific products and components:

(1) Complete automotive steering wheels

(2) Steering wheels with integrated airbag modules

(3) Steering wheel frames and metal skeletons

(4) Steering wheel spokes and rim structures

(5) Steering wheels with multifunction control modules

(6) Steering wheel assemblies used in passenger vehicles and commercial vehicles

Standards

The Steering Wheel Integrated Fatigue Durability Test Bench is designed in accordance with the following standards:

(1) QHMA 2128-2015 – Technical Requirements for Steering Wheels with Airbags, Clauses 7.6.1 and 7.6.2

(2) QHMD 2002-2009 – Steering Wheel Specification, Clauses 7.6.1 and 7.6.2

(3) ISO 4130 – Road Vehicles – Steering Wheel Strength Test

(4) ISO 7401 – Road Vehicles – Lateral Impact Test Method (related durability reference)

(5) SAE J944 – Steering Control Effort and Fatigue Evaluation

(6) GB/T 17675 – Steering Wheel Test Methods

(7) OEM-specific steering wheel fatigue and durability specifications

Parameters

| Item | Specification |

|---|---|

| Load capacity | 2000 N |

| Load measurement range | 40 – 2000 N |

| Load measurement accuracy | ±1% |

| Load resolution | 0.1 N |

| Displacement measurement range | 200 mm |

| Displacement accuracy | ±1% FS |

| Test frequency | 1 – 4 Hz |

| Test waveform | Sinusoidal |

| Power supply | AC 220 V, 50 Hz |

| Rated power | 2 kW |

| Number of channels | 4 channels |

| Applicable steering wheel diameter | 370 ± 50 mm |

Features

(1) Full-range load capability without load segmentation.

(2) Simple and convenient load calibration method with easy operation.

(3) Test data stored in a database for post-test analysis and curve review.

(4) Test interface based on virtual instrument technology with oscilloscope-style curve display.

(5) Editable test programs including test load, test cycles, frequency, and displacement protection limits, with program storage and recall capability.

(6) Recording of load peak and displacement peak for each loading cycle, with load–time and displacement–time curves displayed.

(7) Curve segment storage at intervals of five or more cycles.

(8) Closed-loop force control realized through servo motor control, enabling precise force regulation.

(9) Overload alarm and protection, specimen fracture alarm, and three-color warning light indication.

(10) Sinusoidal waveform loading with zero or non-zero initial force.

(11) Convenient specimen clamping design in accordance with ergonomic requirements.

Accessories

(1) Servo electric actuator

(2) Load sensor

(3) Measurement and control cabinet

(4) Industrial computer

(5) Controller and high-speed data acquisition card

(6) Test control and analysis software

Test Procedures

(1) Install the steering wheel specimen on the fixture and secure it according to the test requirement.

(2) Connect the load sensor and displacement measurement system.

(3) Select load control or displacement control mode through the control software.

(4) Set test parameters including load value, waveform, frequency, and number of cycles.

(5) Start the test to apply cyclic bending and/or torsional loads.

(6) Monitor real-time load and displacement curves during the test.

(7) Complete the test and analyze stored data and fatigue results.

Maintenance Information

(1) Periodically calibrate load sensors and displacement sensors.

(2) Inspect servo actuators and fixtures for mechanical wear.

(3) Check electrical connections and grounding regularly.

(4) Maintain cleanliness of the control cabinet and cooling system.

(5) Perform routine software backup and system diagnostics.

FAQ

1. What is this equipment used for?

It is used to evaluate the fatigue durability of automotive steering wheels under bending and torsional cyclic loading.

2. What types of tests can be performed?

Integrated bending and torsional fatigue tests, as well as pure bending fatigue durability tests.

3. How is test accuracy ensured?

Through closed-loop servo control, high-precision load sensors, and real-time data acquisition.

4. Is the test program adjustable?

Yes. Test parameters can be edited, saved, and recalled for repeated testing.

5. Which users typically use this system?

Automotive OEMs, steering wheel manufacturers, component suppliers, and third-party testing laboratories.

Leave Message Get Price