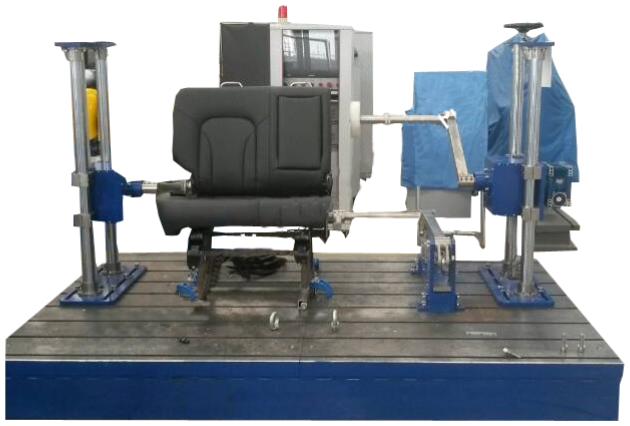

Seat Multifunction Durability Test Bench

The Seat Multifunction Durability Test Bench is a servo-motor-driven integrated testing system designed for comprehensive durability evaluation of automotive seats. The system supports long-term cyclic testing under controlled force and displacement modes, enabling accurate simulation of real vehicle usage conditions. It is suitable for commercial vehicles, light-duty vehicles, micro vehicles, and passenger cars, covering multiple seat structures and functional components. The test bench complies with industry and OEM durability requirements and is widely used in automotive testing laboratories and seat manufacturing facilities.

Application

The Seat Multifunction Durability Test Bench is used for durability and life-cycle testing of the following specific products and components:

(1) Complete automotive seat assemblies

(2) Seat folding mechanisms

(3) Center armrests and side armrests

(4) Seat backrests and recliner mechanisms

(5) Seat slide rails and adjusters

(6) Seat cushions under cyclic loading

(7) Easy-entry seat mechanisms

(8) Electric seat adjustment systems

(9) Headrest fore-and-aft adjustment mechanisms

It is applicable to durability validation during product development, quality control, and type approval testing.

Standards

The Seat Multifunction Durability Test Bench is designed with reference to the following standards and OEM specifications:

(1) QC/T 2005 – Automotive Seat Performance and Durability Requirements

(2) MES – Automotive Seat Durability Test Specifications

(3) Johnson Controls Seat Durability Test Methods

(4) Nissan Motor Seat Durability and Life Test Specifications

(5) GB 15083 – Motor Vehicle Seats, Seat Anchorages, and Head Restraints

(6) ISO 10542 – Seating Systems Durability and Safety Requirements

(7) SAE J879 – Motor Vehicle Seat Systems

Parameters

| Item | Specification |

|---|---|

| Operating temperature | 10 – 45 °C |

| Relative humidity | 10 – 90% RH |

| Power supply | AC 220 V (1 ± 15%) / 50 Hz or AC 380 V |

| Pneumatic supply pressure | 0.6 – 0.7 MPa (dry compressed air) |

| Electromagnetic interference resistance | Suitable for high-interference environments |

| Force sensor range | ±500 N |

| Force measurement accuracy | 0.2% FS |

| Force control accuracy | ±1% |

| Sampling and control frequency | 1000 Hz |

| Maximum load measurement | 2000 N |

| Load cylinder stroke | 300 mm |

| Armrest speed range | 0 – 300°/s |

| Test frequency | 10 – 40 cycles/min |

Features

(1) High-precision servo motor control system enabling both force control and displacement control.

(2) Smooth and stable switching between different control modes during testing.

(3) Integrated software platform with complete data analysis capability.

(4) Test data stored in a database for retrieval, reuse of test methods, and historical playback.

(5) High system stability with proven performance in multiple testing centers and seat manufacturers.

(6) Modular design supporting multiple durability test functions on a single platform.

(7) Suitable for long-duration cyclic testing with reliable repeatability.

Accessories

(1) Servo motor drive system

(2) High-precision force sensors

(3) Pneumatic load cylinders

(4) PC-based control and data acquisition software

(5) Standard seat fixtures and mounting components

(6) Operation and maintenance manual

Test Procedures

(1) Install the seat or seat component onto the test bench using appropriate fixtures.

(2) Select the required durability test module and corresponding test method.

(3) Set force, displacement, speed, and cycle parameters via the control software.

(4) Calibrate force sensors and verify system status.

(5) Start the test and monitor real-time force and displacement data.

(6) Automatically record and store test data throughout the test cycle.

(7) Stop the test upon completion and inspect the test specimen for functional degradation or failure.

Maintenance Information

(1) Regularly inspect servo motors, cylinders, and mechanical joints.

(2) Ensure stable pneumatic supply and clean compressed air.

(3) Periodically calibrate force sensors to maintain measurement accuracy.

(4) Clean fixtures and moving components to prevent debris accumulation.

(5) Back up test data and maintain the software database regularly.

FAQ

1. What is this product?

It is an integrated durability testing system designed for automotive seat assemblies and seat components.

2. What is it used for?

It is used to evaluate the long-term durability and functional reliability of seats under cyclic loading conditions.

3. Why is this test important?

Durability testing ensures seat safety, comfort, and reliability throughout the vehicle’s service life.

4. Which industries is it suitable for?

Automotive testing laboratories, vehicle manufacturers, and seat production facilities.

5. What types of tests can it perform?

Seat folding durability, armrest durability, easy-entry mechanisms, seat cushion loading, backrest durability, slide rail durability, recliner durability, and headrest adjustment durability.

Leave Message Get Price