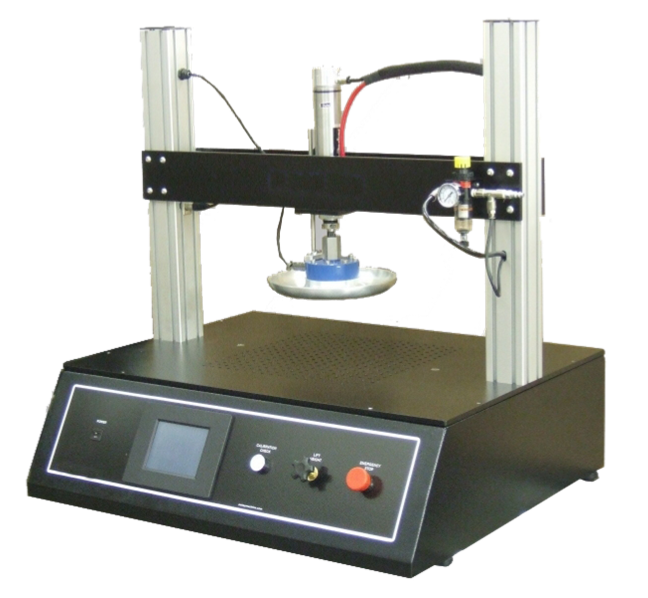

Pneumatic Foam Fatigue Tester

The Pneumatic Foam Fatigue Testing Machine is designed for dynamic fatigue testing of foam materials under constant compressive force. The equipment is available in single-station benchtop and gantry-type configurations, allowing testing at any position on a mattress or foam specimen. The system is pneumatically driven and controlled by a PLC, operating in conjunction with a 500 lbf load cell and signal conditioner to ensure stable force control and repeatable fatigue cycles.

The machine applies a verified peak compressive force of 750 N at a fixed cycle rate of 70 cycles per minute. Other indenter sizes, cycle speeds, and peak force values can be provided upon request. The system is specifically designed for standard square foam specimens in accordance with applicable foam fatigue testing standards.

Application

This testing machine is used for fatigue durability evaluation of foam products subjected to repeated compressive loading, including:

Mattress foam cores and comfort layers

Upholstered furniture foam (sofa cushions, seating pads)

Polyurethane and polymer foam blocks

Elastic foam materials for bedding and seating systems

The equipment supports quality control, product development, and durability assessment in research laboratories, foam manufacturers, and furniture and mattress production facilities.

Standards

The Pneumatic Foam Fatigue Testing Machine complies with or is designed in reference to the following international standards:

(1) ASTM D3574-03 – Flexible Cellular Materials — Slab, Bonded, and Molded Urethane Foams (Constant Force Pounding Dynamic Fatigue Test)

(2) ASTM D3574 – Flexible Cellular Materials — Dynamic Fatigue Testing Methods

(3) ISO 3385 – Polymeric Materials, Cellular Flexible — Determination of Fatigue by Constant-Load Pounding

(4) ISO 2439 – Flexible Cellular Polymeric Materials — Determination of Hardness

(5) GB/T 10807 – Flexible Cellular Polymeric Materials — Determination of Fatigue Performance

(6) EN 1957 – Furniture — Beds and Mattresses — Test Methods for Durability

Parameters

| Parameter | Specification |

|---|---|

| Test station | 1 |

| Drive mode | Pneumatic |

| Control system | PLC control |

| Load measurement | 500 lbf load cell |

| Cycle rate | 70 cycles per minute (CPM) |

| Maximum applied force | 750 N |

| Force accuracy | ±20 N |

| Indenter diameter | 250 mm |

| Cylinder type | Dual-rod NFPA pneumatic cylinder |

| Test specimen type | Standard square foam sample |

| Transportation weight | 105 lbs |

Features

Pneumatic fatigue loading system with stable and repeatable force output.

PLC-controlled operation with preset cycle count and automatic stop function.

Equipped with a 500 lbf load cell and signal conditioner for accurate force monitoring.

Fixed cycle rate of 70 CPM in accordance with standard test requirements.

250 mm diameter foam indentation foot for uniform load distribution.

Dual-rod NFPA pneumatic cylinder ensures alignment stability during testing.

Suitable for benchtop and gantry-type configurations.

Simple operation with minimal parameter setup.

Accessories

(1) Pneumatic foam fatigue testing main unit

(2) 250 mm foam indentation indenter

(3) PLC control system

(4) 500 lbf load cell and signal conditioner

(5) Pneumatic cylinder assembly

(6) Operation manual

(7) Calibration and inspection documentation

Test Procedures

Place the square foam specimen on the perforated support grid.

Align the foam indenter centrally above the specimen.

Set the required number of compression cycles on the PLC controller.

Start the test; the pneumatic cylinder applies a compressive force of 750 ±20 N.

The cylinder retracts after each compression to complete one cycle.

The system operates at 70 cycles per minute until the preset count is reached.

The machine stops automatically upon test completion.

Remove the specimen and visually assess deformation and thickness change.

Maintenance Information

Regularly inspect pneumatic cylinders and air lines for leakage.

Check load cell calibration at scheduled intervals.

Clean the indenter surface and support grid after each test.

Ensure compressed air supply is clean and dry.

Disconnect air and power supply when the equipment is not in use.

FAQ

1. What is this machine used for?

It is used for dynamic fatigue testing of foam materials under constant compressive force.

2. What type of specimens can be tested?

Standard square foam samples used in mattress, furniture, and seating applications.

3. How is the compressive force applied?

The force is applied pneumatically using a dual-rod cylinder and monitored by a load cell.

4. Does the machine stop automatically after testing?

Yes. The system stops automatically once the preset cycle count is completed.

5. Can test force and speed be customized?

Yes. Other force levels, indenter sizes, and cycle speeds are available upon request.

Leave Message Get Price