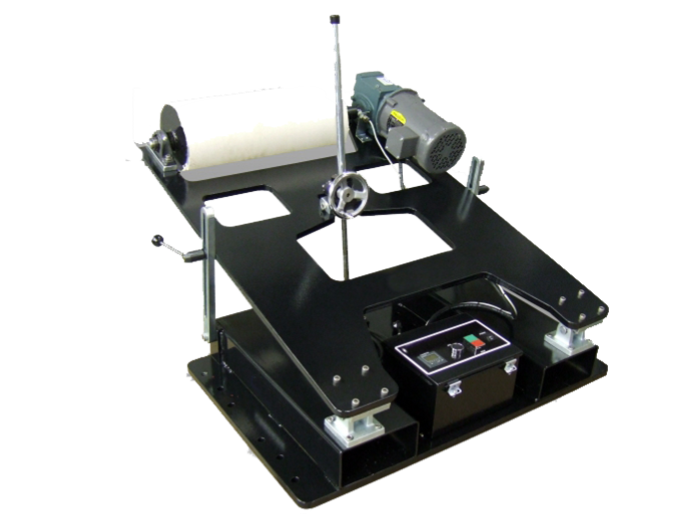

Headrest Abrasion Testing Machine

The Headrest Abrasion Testing Machine is a single-station test device designed for continuous friction testing of seat headrests or complete seats. The equipment operates on either 110 VAC or 230 VAC single-phase power and performs controlled abrasion between the test specimen and a rotating drum. The machine is designed to support abrasion durability evaluation under repeatable mechanical conditions.

Application

This testing machine is used for abrasion resistance evaluation of headrest materials and surface coverings, including:

Automotive seat headrests

Sofa and furniture headrests

Safety and protective cushions

Upholstered padding materials

The system allows simple operation by presetting the required number of test cycles. After completion, the specimen is visually inspected to assess surface wear and abrasion resistance.

Standards

The equipment is designed in accordance with relevant abrasion and durability testing principles and supports the following standards (depending on test configuration):

ASTM D4966 – Martindale abrasion resistance (reference method)

ASTM D3884 – Rotary platform abrasion resistance

ISO 12947 – Textiles — Determination of abrasion resistance

ISO 17076 – Automotive interior material durability testing

SAE J948 – Automotive interior trim material testing

GB/T 21196 – Textile abrasion resistance testing

Parameters

| Parameter | Specification |

|---|---|

| Test station | Single station |

| Test mode | Continuous friction abrasion |

| Cycle control | Preset cycle counter with automatic stop |

| Angle adjustment | Adjustable |

| Speed control | Adjustable |

| Drive motor | 1/4 HP motor |

| Motor voltage | 480 VAC, 3-phase (with internal voltage/phase converter) |

| Control power supply | 115 VAC, 60 Hz (other voltages and frequencies available) |

| Operation | Electric |

| Evaluation method | Visual inspection |

Features

Automatic cycle counter with preset stop function.

Adjustable test angle to accommodate different headrest geometries.

Equipped with a 1/4 HP motor and internal voltage/phase conversion system.

Variable speed control for different abrasion test requirements.

Supports 50 Hz and 60 Hz power supply operation.

Simple operation with reliable and repeatable test execution.

Accessories

(1) Headrest abrasion test main unit

(2) Rotating abrasion drum

(3) Cycle counter controller

(4) Speed control unit

(5) Power conversion module

(6) Operation manual

(7) Calibration and inspection documents

Test Procedures

Install the headrest or test specimen on the test fixture.

Adjust the test angle and contact position as required.

Set the rotation speed of the abrasion drum.

Input the required number of test cycles into the cycle counter.

Start the test; the specimen contacts the rotating drum continuously.

The machine automatically stops after reaching the preset cycle count.

Remove the specimen and perform visual inspection to evaluate abrasion performance.

Maintenance Information

Regularly inspect the rotating drum and contact surfaces for wear.

Ensure motor ventilation openings are free from dust and debris.

Check electrical connections and speed controller operation periodically.

Clean the test fixture and surrounding area after each test.

Disconnect power supply when the machine is not in use.

FAQ

1. What is this product?

It is a headrest abrasion testing machine for evaluating surface wear resistance under repeated friction.

2. What is it used for?

It is used to assess abrasion durability of automotive and furniture headrest materials.

3. How are test results evaluated?

Results are evaluated by visual inspection of surface wear after completion of preset cycles.

4. Can the test angle and speed be adjusted?

Yes, both test angle and abrasion speed are adjustable.

5. Which industries typically use this equipment?

Automotive seating manufacturers, furniture producers, material testing laboratories, and quality inspection institutions.

Leave Message Get Price