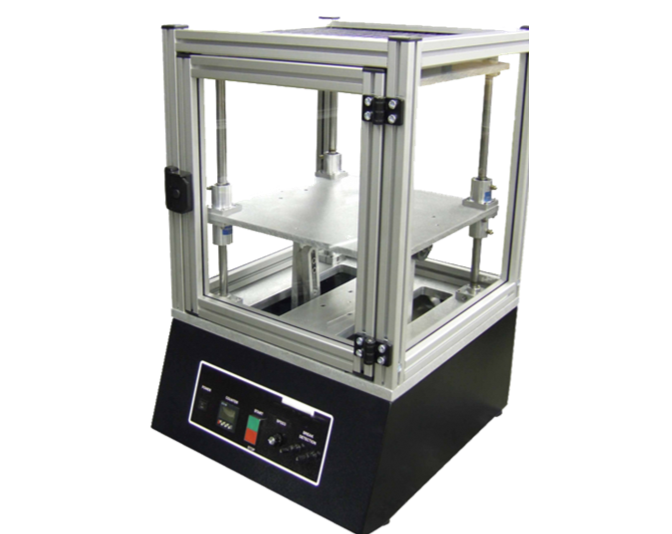

Universal Compression Fatigue Testing Machine

The Universal Compression Fatigue Testing Machine is designed for fixed-displacement compression fatigue testing of springs and elastic components. Originally developed for mattress spring durability evaluation, the system has been expanded to support a wide range of compression fatigue applications. It provides stable cyclic loading, reliable failure detection, and long-term endurance testing under controlled displacement conditions.

Application

This machine is used for compression fatigue and durability testing of elastic and load-bearing components, including:

Mattress springs and spring units

Furniture springs and cushioning systems

Automotive seat springs and suspension springs

Rubber blocks and elastomer components

Metal coil springs and compression elements

Industrial elastic components subjected to repeated compression

It is suitable for quality control, product development, and endurance testing in furniture, automotive, bedding, and component manufacturing industries.

Standards

The testing system is designed to comply with or support the following relevant international and industry standards (depending on configuration and test method):

(1) ISO 3385 – Mattress assessment — Durability testing

(2) ISO 7500-1 – Verification of static uniaxial testing machines

(3) ASTM F1566 – Standard Test Methods for Evaluation of Mattress Durability

(4) ASTM E9 – Compression testing of metallic materials

(5) ASTM D575 – Rubber properties in compression

(6) SAE J157 – Testing of automotive seat cushioning and spring components

(7) GB/T 26706 – Mattress durability and fatigue testing

(8) GB/T 7757 – Rubber compression set test methods

Parameters

| Parameter | Specification |

|---|---|

| Test mode | Fixed-displacement compression fatigue |

| Stroke | Adjustable |

| Opening height | Adjustable |

| Control mode | Programmable up-counter control |

| Speed control | Adjustable low speed and test speed |

| Drive motor | High-quality brushless motor |

| Stop function | Automatic shutdown upon failure detection |

| Failure detection | Continuous monitoring of spring condition |

| Optional detection | Compatible with crack gauge or similar devices |

| Structural materials | Aluminum and stainless steel |

| Surface treatment | Powder coating and anodized finish |

| Power supply | Configurable (must be specified at order) |

Features

Adjustable stroke and opening height to accommodate various specimen sizes.

Programmable up-count controller enables automatic stop after preset cycles.

Continuous inspection of test specimens with automatic shutdown upon failure.

Compatible with crack gauges or similar failure detection devices.

Mechanical components manufactured from aluminum and stainless steel for durability.

Powder-coated and anodized surfaces provide corrosion resistance and long service life.

Independently adjustable low-speed positioning and test-speed operation.

High-quality brushless motor ensures stable performance and low maintenance.

Accessories

(1) Compression test frame

(2) Programmable control unit

(3) Brushless drive motor

(4) Adjustable compression platens

(5) Failure detection system

(6) Electrical control cabinet

(7) Operation and maintenance manual

(8) Calibration documentation

Test Procedures

Install the test specimen between the compression platens.

Adjust opening height and stroke according to test requirements.

Set preload displacement or initial compression condition.

Configure test speed and target cycle count on the controller.

Start the test and monitor system operation.

The machine continuously checks specimen condition during testing.

Testing stops automatically upon reaching preset cycles or specimen failure.

Record test results and remove the specimen after completion.

Maintenance Information

Regularly inspect mechanical moving parts for wear or looseness.

Keep guide rails and transmission components clean and lubricated.

Check electrical connections and controller settings periodically.

Inspect failure detection devices for proper function.

Clean dust and debris from the machine surface and internal areas.

Disconnect power supply when the machine is not in use.

FAQ

1. What is this product?

It is a compression fatigue testing machine designed for fixed-displacement cyclic compression testing.

2. What is it used for?

It is used to evaluate fatigue life, durability, and failure behavior of springs and elastic components under repeated compression.

3. Why is it important?

It ensures product durability, safety, and consistent performance under long-term compression loading.

4. Which industries is it suitable for?

Furniture manufacturing, bedding and mattress production, automotive seating, rubber products, and component testing laboratories.

5. What types of tests can be performed?

Compression fatigue testing, durability evaluation, endurance testing, and failure life assessment under cyclic compression.

Leave Message Get Price