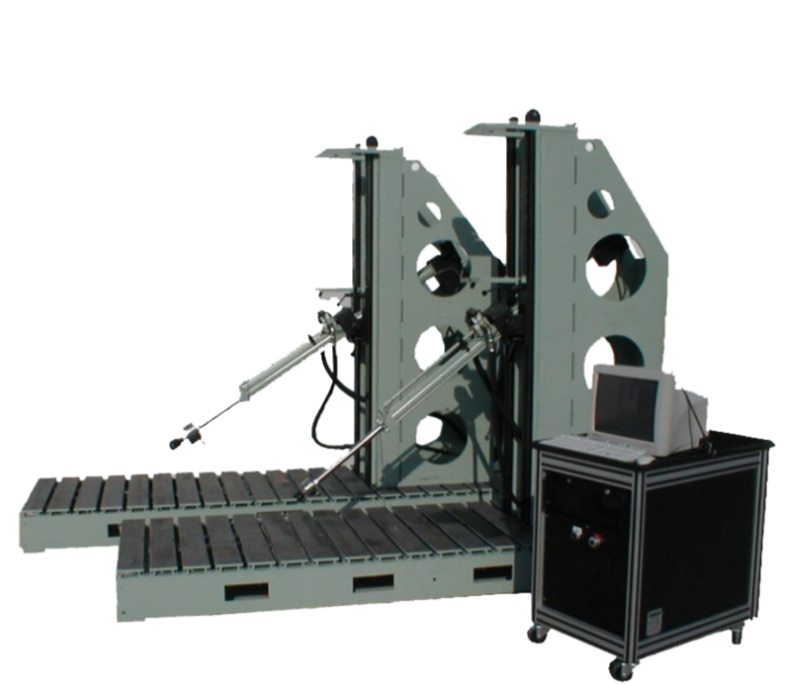

Hydraulic Continuous Fatigue and Tensile Testing Machine

The Hydraulic Continuous Fatigue and Tensile Testing Machine is a dual-function electro-hydraulic servo test system designed to perform either tensile testing or continuous fatigue testing independently. The system is engineered for high-load, long-cycle durability evaluation of components and assemblies, particularly in automotive seating and safety-related applications. Each test station operates independently and is driven by a centralized hydraulic power unit with a dedicated PC-based control and data acquisition system.

Application

This testing machine is widely used for mechanical performance verification of components subjected to repeated loading or static tensile forces, including but not limited to:

Automotive seats and seat structures

Seat rails, seat frames, and adjustment mechanisms

Seat belts, anchors, and fastening components

Interior structural brackets and welded assemblies

Metal and composite structural components

Rubber, polymer, and elastomer fatigue specimens

It is suitable for both laboratory qualification testing and production quality validation in automotive, transportation, and component manufacturing industries.

Standards

The system is designed to meet or support the requirements of the following international and industry-related standards (test methods configurable):

(1) ISO 7500-1 – Metallic materials — Verification of static uniaxial testing machines

(2) ISO 13003 – Fibre-reinforced plastics — Fatigue testing under cyclic loading

(3) ASTM E466 – Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests

(4) ASTM E9 – Compression testing of metallic materials at room temperature

(5) SAE J328 – Fatigue testing of automotive components

(6) SAE J1367 – Seat strength and durability evaluation

(7) GB/T 16825.1 – Verification of static uniaxial testing machines

(8) GB/T 3075 – Axial force-controlled fatigue testing methods

Parameters

| Parameter | Specification |

|---|---|

| Test functions | Tensile test or continuous fatigue test (selectable, not simultaneous) |

| Test stations | Single or multi-station (example shown: 2 stations) |

| Cylinder stroke | 24 inches (610 mm) |

| Cylinder type | Double-rod hydraulic cylinder |

| Maximum capacity per cylinder | Up to 10,000 lbf (≈44.5 kN) |

| Load measurement | Fatigue-rated load cell |

| Displacement measurement | Internal displacement transducer (independent rotation) |

| Mounting structure | Balanced two-axis universal joint mounting |

| Motion freedom | Free movement or lockable in vertical and transverse axes |

| Control system | PC-based independent control and data acquisition |

| Software platform | Windows-based, Visual Basic architecture |

| Hydraulic power unit | Independent, floor-mounted |

| Operating pressure | Workshop hydraulic pressure |

| Power supply | 115 VAC standard (other voltages available) |

Features

Dual-function system capable of performing tensile or continuous fatigue tests independently.

Modular multi-station design allows independent programming and operation of each cylinder.

Electro-hydraulic servo control ensures stable load application and precise waveform control.

Balanced universal joint mounting eliminates misalignment effects during testing.

Large-stroke double-rod cylinders provide uniform load distribution and long fatigue life.

Real-time graphical display of load, displacement, and cycle data.

User-friendly PC software with simple setup and rapid operator learning curve.

Independent hydraulic servo valve and controller for each test station.

Floor-standing control cabinet separates electronics from mechanical vibration sources.

Accessories

(1) Hydraulic test frame with cylinders

(2) Independent hydraulic power unit

(3) PC control and data acquisition system

(4) Fatigue-rated load sensors

(5) Displacement transducers

(6) Universal joint mounting assemblies

(7) Operation and maintenance manual

(8) Calibration certificate

Test Procedures

Install the test specimen securely between the grips or fixtures.

Select tensile or fatigue test mode in the control software.

Configure load range, waveform, frequency, and cycle count (fatigue mode) or loading rate (tensile mode).

Zero load and displacement sensors.

Start the test and monitor real-time data and graphical output.

The system records load, displacement, cycles, and failure points automatically.

Upon test completion, save and export test reports.

Remove specimen and prepare for the next test cycle.

Maintenance Information

Proper maintenance ensures long-term reliability and performance:

Regularly replace hydraulic oil filters to maintain system cleanliness.

Periodically replace hydraulic oil and monitor oil quality.

Inspect and service servo valves at scheduled intervals.

Replace sealing rings and wear components as part of preventive maintenance.

Avoid surface scratches or impact damage to cylinders and fixtures.

Inspect internal components before each operation for abnormal conditions.

Keep the system clean and free from dust accumulation.

Disconnect power supply when the equipment is not in use.

FAQ

1. What is this product?

It is an electro-hydraulic servo testing machine designed for tensile and continuous fatigue testing of components and materials.

2. What is it used for?

It is used to evaluate static tensile strength and fatigue durability under cyclic loading conditions.

3. Why is it important?

It ensures the safety, durability, and reliability of automotive and structural components under real-world loading conditions.

4. Which industries is it suitable for?

Automotive manufacturing, transportation equipment, component suppliers, research laboratories, and quality inspection centers.

5. What types of tests can be performed?

Tensile strength testing, force-controlled fatigue testing, durability evaluation, and fracture-related mechanical testing.

Leave Message Get Price