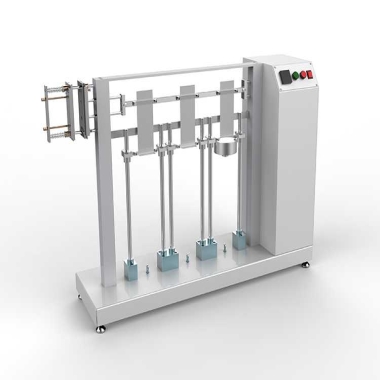

Chrysler Bending Tester

1. Product Introduction & Applications

The Chrysler Bending Tester is designed to evaluate the bending and folding performance of coated fabrics and leather, assessing the mechanical stability and adhesion of coatings. It is based on the Chrysler Laboratory Test Method LP-463LB-9-01.

Applications:

Evaluates adhesion and mechanical stability of vinyl-coated fabrics, leather, and similar materials.

Detects whitening, cracking, lamellar separation, and unsupported rupture in coatings.

Applicable to soft furnishings, leather products, and vinyl-coated materials.

Simultaneous testing of multiple specimens for bending and folding behavior.

2. Product Advantages

Simultaneous Multi-Sample Testing: Four specimens can be tested at once — three for bending and one for folding.

Controlled Tension: Adjustable weights ensure consistent tension on bending specimens.

Adjustable Loads: Bending and folding loads can be set according to test requirements.

Quantitative Evaluation: Measures the coating’s resistance to mechanical stress and folding fatigue.

Electronic Counter: Six-digit counter tracks the number of cycles for precise monitoring.

Desktop Design: Compact structure suitable for lab benchtop use.

3. Product Features

Bending Test:

Three stations for bending specimens.

Sample clamped at both ends; one end fixed, the other moves horizontally.

Tension applied with fixed weight; 36 N (8 lbf.) bending load, adjustable.

Folding Test:

One station for folding specimen.

Sample clamped between opposing plates; 641 N (12 lbf.) folding load applied.

Ensures controlled and uniform pressure during fold.

Sample Sizes:

Bend specimens: 76 × 203 mm (3 × 8 in)

Folding specimen: 129 × 129 mm (5 × 5 in)

Cycle Tracking:

Manually resettable electronic counter.

6-digit display for precise cycle counting.

Compact Desktop Design:

Desktop footprint with durable mechanical construction.

Easy operation and sample replacement.

4. Technical Parameters

| Item | Specification |

|---|---|

| Bending Test Stations | 3 |

| Folding Test Station | 1 |

| Rod Working Stroke | 70 mm (2.75 in) |

| Fixture Spacing | 152 mm (6 in) |

| Working Frequency | 35 cycles/min |

| Bending Load | 36 N (8 lbf), adjustable |

| Folding Load | 641 N (12 lbf) |

| Bend Test Specimen Size | 76 × 203 mm (3 × 8 in) |

| Folding Test Specimen Size | 129 × 129 mm (5 × 5 in) |

| Electronic Counter | 6 digits, manually resettable |

| Dimensions (L × W × H) | 36 × 12 × 20 in |

| Design Type | Desktop |

5. FAQ

Q1: How many samples can be tested simultaneously?

A1: Three bending specimens and one folding specimen can be tested at the same time.

Q2: Are the loads adjustable?

A2: Yes, both bending and folding loads are adjustable to meet different test requirements.

Q3: What types of materials can be tested?

A3: Vinyl-coated fabrics, leather, soft furnishings, and similar coated materials.

Q4: How is the test cycle monitored?

A4: A six-digit electronic counter tracks the number of bending/folding cycles and is manually resettable.

Leave Message Get Price