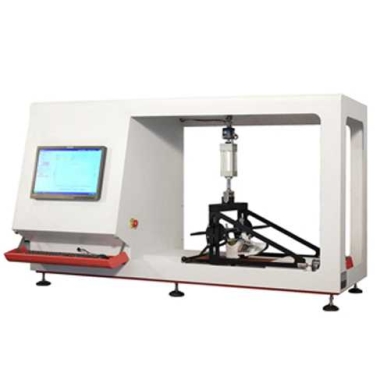

Shoe Slip Resistance Tester

1. Product Introduction & Applications

The Shoe Slip Resistance Tester is designed based on extensive biomechanical research to replicate real-world walking conditions and evaluate the slip resistance of shoes and soles under dynamic situations.

During normal walking, the heel contacts the ground first, followed by the toes. The highest risk of slipping occurs when the heel is lifted and the toes bear nearly half the body weight. This tester simulates this critical phase to assess footwear safety.

Applications:

Testing dynamic slip resistance of shoes, soles, and other footwear materials.

Evaluating footwear safety for occupational, athletic, or daily use.

Quality control during production to ensure consistent anti-slip performance.

Research and development of high-traction shoe designs.

Testing of shoe materials against standardized anti-slip flooring or custom surfaces.

The device can be used with a calibrated standard test floor or other types of ground surfaces (sold separately), as long as the surface can be mounted and interfaced with the tester.

2. Conformity Standards

The tester is compatible with industry-standard slip resistance testing methods and can be used with standard surfaces to generate reliable and comparable results.

Standards references include:

ASTM F2913 — Standard Test Method for Slip Resistance of Footwear and Test Surfaces (Whole Shoe Tester)

BS EN 13287 — Test Method for Slip Resistance of Personal Protective Footwear

GB/T 28287 — Foot Protection: Test Method for Footwear Slip Resistance

3. Technical Parameters

| Parameter | Specification |

|---|---|

| Test Mode | Simulates heel lift phase during normal walking |

| Measurement | Dynamic coefficient of friction (COF) |

| Control System | Integrated data acquisition with real-time friction analysis |

| Movement Control | Variable speed motor for precise simulation of walking forces |

| Ground Surfaces | Standard calibrated floor (included) or compatible alternative surfaces |

| Force Control | Unique circuit design to maintain required speed and load |

| Power Supply | AC 220V, 50Hz (typical) |

| Data Output | Real-time display of friction coefficient per specimen |

Key Features:

Dynamic Simulation: Accurately replicates heel-lift and toe-weighted walking phase.

Standardized & Custom Surfaces: Can test shoes against standard or custom anti-slip surfaces.

Precision Control: Integrated motor and circuit design ensure consistent force and speed.

Data Acquisition: Provides real-time friction coefficient measurements for each specimen.

Versatile Testing: Suitable for various footwear types and materials.

4. FAQ

Q1: What types of shoes can be tested?

A1: All types of finished footwear including athletic, casual, safety, and work shoes.

Q2: How does the tester simulate real walking slips?

A2: By replicating the critical heel-lift phase where the toes bear half the body weight, the tester evaluates dynamic slip resistance.

Q3: Can different floor surfaces be tested?

A3: Yes, the tester comes with a standard calibrated surface, and other compatible surfaces can be used as long as they can be connected to the tester.

Q4: What data is provided by the tester?

A4: The tester provides the dynamic coefficient of friction (COF) for each specimen in real time.

Q5: How is test consistency ensured?

A5: The integrated motor and controller maintain precise speed and force during each test cycle, ensuring repeatable and reliable results.

Leave Message Get Price