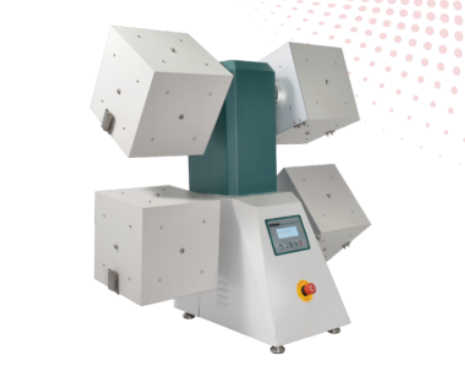

Fabric ici pilling and snagging box

The Fabric ICI Pilling and Snagging Box is designed to evaluate pilling resistance and snagging performance of textiles, simulating real-world wear conditions. Its multi-box design enables high-throughput testing with precise, repeatable results. The system is ideal for laboratories, QC departments, and textile research facilities.

Standards Compliant

| Standard | Scope |

|---|---|

| GB/T 4802.3 | Textile pilling resistance – China National Standard |

| BS EN ISO 12945-1 | Wool-based textile pilling evaluation – European Standard |

| BS 5811 / IWS TM152 / NEXT TM19 | UK retail and industrial specifications |

| M&S P18A / P18B / P21A | Marks & Spencer proprietary quality benchmarks |

| BS 8479 | Fabric snagging resistance – British Standard |

Applications

Pilling evaluation of woven, knitted, wool, and blended fabrics

Snagging assessment for garments, upholstery, and technical textiles

Quality control and batch verification in textile manufacturing

Research and development for new textile materials and finishes

Product Advantages

Versatile Speed Control: Adjustable rotation speeds from 20–70 rpm for standardized or custom testing protocols.

Bidirectional Testing: Forward/reverse rotation at 30 rpm to mimic real-world fabric wear.

High-Throughput Design: 4 pilling boxes + 2 snagging boxes allow 6 samples to be tested simultaneously.

Intelligent Operation: LCD display for real-time monitoring; auto-stop and audible alarms at cycle completion.

Durability: Sealed motor housing prevents dust ingress; automatic pause protects components.

Precision Engineering: Digital preset counter ensures repeatable results; includes 30 sample tubes for batch testing.

Product Features

Modular Test Chambers: 4 dedicated pilling boxes (octagonal) and 2 snagging boxes for comprehensive analysis.

Rapid Mounting Jig: Quick-release clamps simplify sample fixation.

Accessories Kit: Cork liners, snagging points, and pilling photograph guide for visual grading.

Motor Safety System: Overload protection and thermal cutoff prevent damage.

Customizable Cycles: User-defined test duration and reversal intervals via LCD interface.

Compact Footprint: Space-saving design with integrated storage for accessories.

Technical Parameters

| Parameter | Specification |

|---|---|

| Test Mode | Automatic |

| Rotation Direction | Unidirectional / Bidirectional (Reversing) |

| Rotation Speed Options | 20, 30, 40, 45, 50, 60, 65, 70 rpm |

| Standard Speed Modes | 60 rpm Unidirectional; 30 rpm Unidirectional; 30 rpm Bidirectional |

| Working Chamber | 4 Pilling Boxes + 2 Snagging Boxes |

| End Alarm | Buzzer |

| Steel Nails Material | Stainless Steel |

| Power Supply | 220V, 50Hz |

| Weight | 75 kg |

| Dimensions (L×W×H) | 900 × 800 × 1100 mm |

Leave Message Get Price