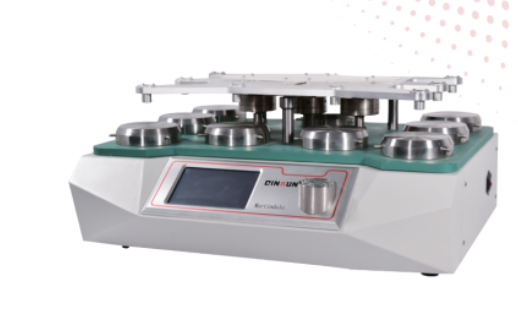

Martindale Abrasion And Pilling Tester

The Martindale Abrasion & Pilling Tester evaluates the abrasion resistance and pilling tendency of all types of textile structures. Fabric samples are rubbed against standard abrasives at low pressures in continuously changing directions, simulating real wear conditions. Test results are compared against standard parameters to assess durability.

The machine features removable individual sample holders, allowing inspection during testing without stopping the top motion plate. Multiple workstations, programmable counters, and interval timers enhance lab efficiency.

Applications

Textile quality control: Apparel, upholstery, technical fabrics, and footwear

Material research and development

Compliance with ISO, ASTM, GB, BS, FZ/T, Woolmark, and other textile standards

Predicting fabric appearance changes, pilling formation, and abrasion performance

Standards Compliant

| Standard | Scope |

|---|---|

| ISO 12947 | Textile abrasion resistance (Martindale method) |

| ISO 5470-2 | Abrasion resistance of coated fabrics |

| GB/T 13775 | Seawater color fastness of textiles |

| GB/T 21196 | Pilling resistance using circular locus method |

| ASTM D4966 | Abrasion resistance of textiles |

| ASTM D4970 | Color fastness to rubbing |

| BS 3424-24 | Water spot color fastness |

| ISO 12945 | Pilling resistance of textiles |

| Woolmark TM196 | Wool shrink-proof certification |

| BS EN 388 | Protective gloves abrasion, cut, tear, puncture |

| ISO 20344 | Footwear testing (abrasion, puncture, slip) |

(Additional standards: GB/T 4802.2, BS-EN-13770, FZ/T 20020, M&S P17, IWTO DRAFT TM40)

Product Features

Multi-Stroke Quick Change: Aerospace-grade aluminum motion plate allows easy sample installation and inspection.

Touch-Screen Operation: Full-color display with bilingual interface (CN/EN), single/multiple test modes, and built-in standard/custom programs.

Adjustable Test Loads: Supports 3, 9, and 12 kPa, with optional puckering test.

Precision Construction: Stainless steel weights and imported aluminum guide plates minimize deviations.

Individual Counters & Parking: Automatic stop when cycles are reached; interval time is programmable.

Highly Automated: Automatic buzzer alerts at preset values; timer countdown available for batch tests.

Removable Sample Holders: Inspect samples without interrupting other tests.

Technical Parameters

| Parameter | Specification |

|---|---|

| Working Stations | 4 |

| Wear Fixture Pressure | 3 kPa, 9 kPa, 12 kPa |

| Pilling Fixture Load | 260 g |

| Wear Fixture Weight | 198 g |

| Pilling Fixture Weight | 155 g |

| Sample Filling Hammer | 2385 ±10 g |

| Stroke – Wear | 5 ±0.5 mm |

| Stroke – Pilling | 24 ±0.5 mm |

| Large Lissajous Figure | 60.5 ±0.5 mm |

| Small Lissajous Figure | 24 ±0.5 mm |

| Test Speed | 47.5 rpm (adjustable ×0.5, ×1.25, ×1.5) |

| Counting Range | 0–999,999 cycles |

| Control Panel | Full-color touch screen |

| Dimensions | 700 × 700 × 450 mm |

| Machine Weight | 70 kg |

| Power Supply | 220V, 50Hz |

Accessories & Consumables

9 specimen holder sets

9 kPa and 12 kPa additional weights

Abradent fabric/backing felt cutters (Ø38 mm & Ø140 mm)

Pilling test suite, SM-50 and EMPA photographic standards

Standard backing foam and felt pieces

Spare blades and other manufacturer-recommended accessories

Leave Message Get Price