Warm-Body Sweat Manikin: A New Tool for Clothing Thermal Comfort Testing

Warm-Body Sweat Manikin: A New Tool for Clothing Thermal Comfort Testing

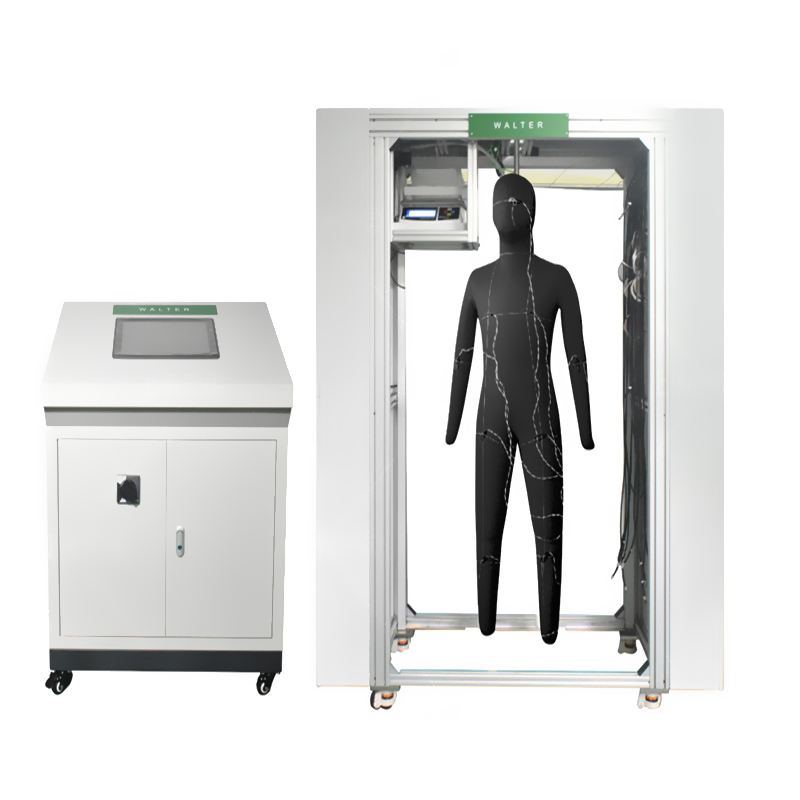

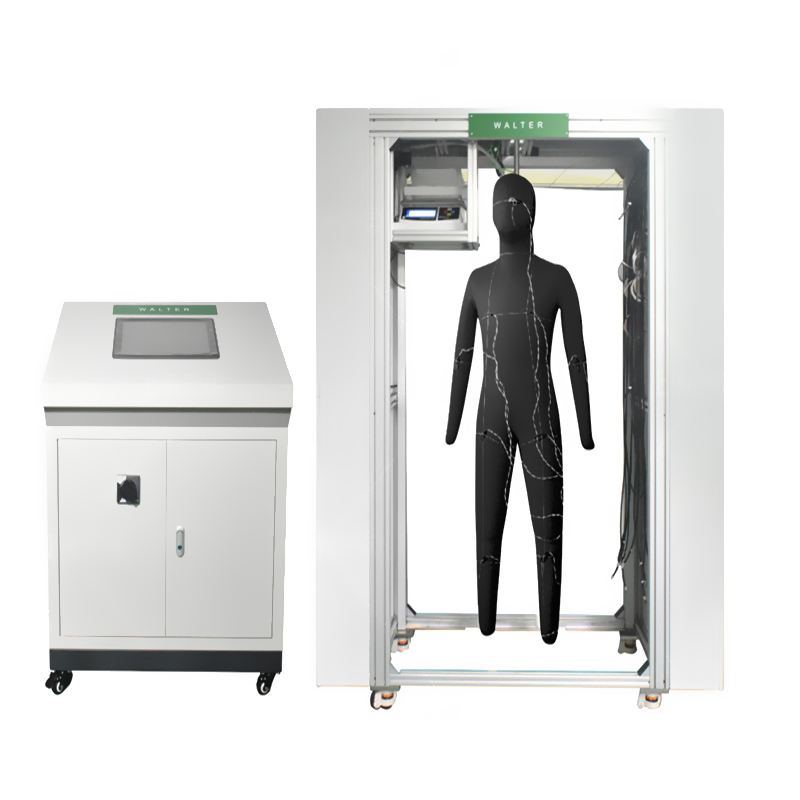

The WALTER Warm Body Sweating Manikin Tester simulates the dry heat exchange processes of conduction,convection,and radiation between the human body,clothing,and the environment,as well as the wet heat exchange processes of evaporative perspiration,under a defined environment.This allows for scientific evaluation of the thermal performance of the garment as a whole or the environment,avoiding the need for real-person testing.This instrument digitizes and homogenizes the perceived results,resulting in high experimental accuracy and excellent repeatability.It can guide the development and production of functional fabrics and clothing,and can also be used to analyze the impact of the environment on human comfort and determine the environmental conditions that meet human comfort requirements.

Compliant Standards:

GB/T 39605-2020"Test Method for Moisture Resistance of Clothing-Sweating Heated Manikin Method"

GB/T 18398-2001"Test Method for Thermal Resistance of Clothing-Sweating Heated Manikin Method"

ISO 15831:2004(E)Clothing.Physiological Effects.Measurement of Thermal Insulation Using a Heated Manikin

ASTM F 1291-04 Standard Test Method for Thermal Insulation of Clothing Using a Heated Manikin

ASTM F 1720 Standard Test Method for Thermal Insulation of Sleeping Bags Using a Heated Manikin

ASTM F 2370 Standard Test Method for Evaporative Resistance of Clothing Using a Sweating Manikin

Technical Parameters:

Operation Mode:Automatic

Mannequin Material:Epoxy Resin

Zones:Over 15 anatomical segments(customizable),including head,neck,chest,abdomen,back,buttocks,and limbs.Rotatable joints are located at the neck,shoulders,elbows,hips,and knees.

Test Temperature Range:10-55°C

Temperature Control Uniformity:±2°C

Temperature Control Accuracy:±0.1°C

Temperature Control Stability:±0.5°C

Heating Power:0-2000W,Accuracy≤1%

Measurement Frequency:50Hz

Control Mode:Over 22 temperature sensors,accuracy±1°C,10 or more humidity sensors,±3%accuracy(customizable)

Human dimensions:Height 170±10 cm,Weight 75 kg

Heating control:Electric heater

Operating modes:Constant temperature test,variable temperature test,constant power test,variable power test

Sweating system:0-2000±50 g/h

Walking speed:0-100 m/min(stepless,customizable),stride length 0-70 cm/step

Test environment:Ambient temperature:-20-80°C,Ambient humidity:0-100%RH

Test posture:Standing,sitting,walking

Power supply:220V 50Hz

Weight:350 kg

Dimensions:900×900×2200 mm

Firefighter Suit R&D and Material Innovation

· Optimization of Moisture-Wicking and Quick-Drying Fabrics: A leading firefighting equipment company utilized 34-zone moisture resistance data to identify the optimal fabric combination for six high-metabolism areas, including the underarms and back. This improved the moisture permeability index (IM) from 0.35 to 0.59 (a 42% increase), extending firefighters' continuous wear time from 2 hours to 3.5 hours, and raising the subjective comfort score (on a 1-10 scale) from 5.2 to 8.7.

Design for extreme environmental adaptability: A university's textile research institute used a mannequin to simulate a low-temperature, high-wind environment on a plateau (-15°C, 2m/s wind speed, 30% relative humidity). The team optimized the three-layer structure of firefighter uniforms: a windproof outer layer, a warm middle layer, and a quick-drying inner layer. This improved the overall thermal resistance (Rct) from 0.18 m²·K/W to 0.23 m²·K/W (a 28% increase). Furthermore, lightweight material selection resulted in a 15% weight reduction (from 3.2 kg to 2.72 kg).

Comfort testing and evaluation of firefighter uniforms: Simulating an enclosed space (35°C, 90% RH, 0.3m/s airflow), the team found that conventional firefighter uniforms exhibited a high moisture resistance of 35 m²·Pa/W at the waist, resulting in a localized skin temperature of 38.5°C. A 34-zone humidity distribution thermogram of the mannequin identified defects in the ventilation structure at the waist. After optimization, the moisture resistance was reduced to 18 m²·Pa/W, and the skin temperature was controlled to 36.8°C.

Leave Message Get Price