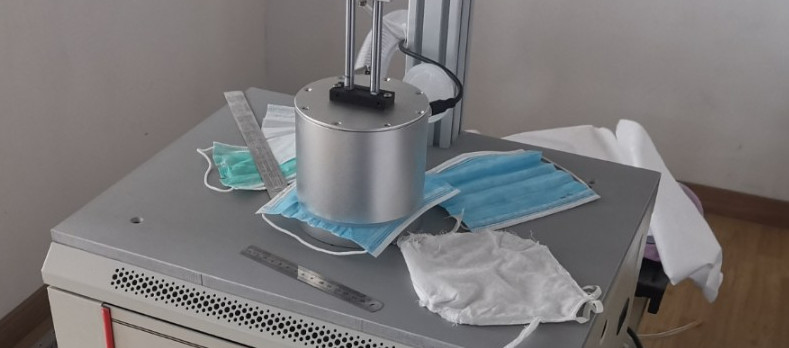

How To Experimental Of Mask Particle Filtration Efficiency Tester?

The Mask Particle Filtration Efficiency Tester simulates the actual environment in which the mask or filter material is used and performs filtration efficiency and filtration resistance tests based on the standard required oil mist and salt spray methods.

The test parameters meet the requirements of NIOSH 42 CFR Part 84 and GB/T 2626. In addition to this, the Mask Particle Filtration Efficiency Tester can also be used to test the permeability of the filter media.

Test aperture: 1/1, 1/2, 1/4, 1/8;

Test material: layered mask or filter material;

Test method: oil mist test and salt spray test;

Test parameters: filtration efficiency, filtration resistance, etc.;

Mask Particle Filtration Efficiency Tester can accurately evaluate the filtration performance of masks or filter materials, and provide data basis for the research and development of new filter materials, product quality control, material performance verification, etc. It is the first choice for product performance verification in scientific research, testing, industrial production and other fields choose.

standard test:

standard reference

(1) YY0469-2011

(2) GB2626-2006

⑶ European standard EN1822-3: 2009

related terms

Filtration efficiency: Under the specified detection conditions, the percentage of particulate matter filtered by the filter element;

Oil mist detection: use DEHS/PAO/DSP and other oily or equivalent substances as aerosols to test the filtration performance of masks or filter materials;

Salt spray method detection: using NaCl or equivalent halides as aerosols to detect the filtration performance of masks or filter materials;

Test Principle:

Oil mist method:

Dry oil-free compressed air enters the aerosol generator at a certain flow rate to produce an aerosol with a certain particle distribution. After being screened by a cascade impactor, the particles with a particle size distribution that meet the standard requirements are discharged from the aerosol outlet and enter the test pipeline.

And reach the filter material, the pressure difference sensor is installed on both sides of the filter material, the number of particles in the upstream and downstream of the filter material is monitored during the test process; the whole test process is carried out with a certain flow rate or air volume.

Salt spray method:

Dry oil-free compressed air enters the aerosol generator at a certain flow rate to produce an aerosol with a certain particle distribution. After being screened by a cascade impactor, the particles with a particle size distribution that meet the standard requirements are discharged from the aerosol outlet and enter the test pipeline.

Since the salt mist aerosol has static electricity, it is necessary to neutralize the salt mist aerosol. And for salt mist aerosols, it needs to be heated to produce salt particles. The method is as follows: the aerosol that meets the particle size requirements is mixed with heating gas, and then the water in the aerosol is evaporated to produce salt particles.

And reach the filter material, the pressure difference sensor is installed on both sides of the filter material, the number of particles in the upstream and downstream of the filter material is monitored during the test process; the whole test process is carried out with a certain flow rate or air volume.

The above is the process of the Mask Particle Filtration Efficiency Tester test experiment. Welcome to leave a message for more information on mask testing equipment.

2023-02-23 14:10