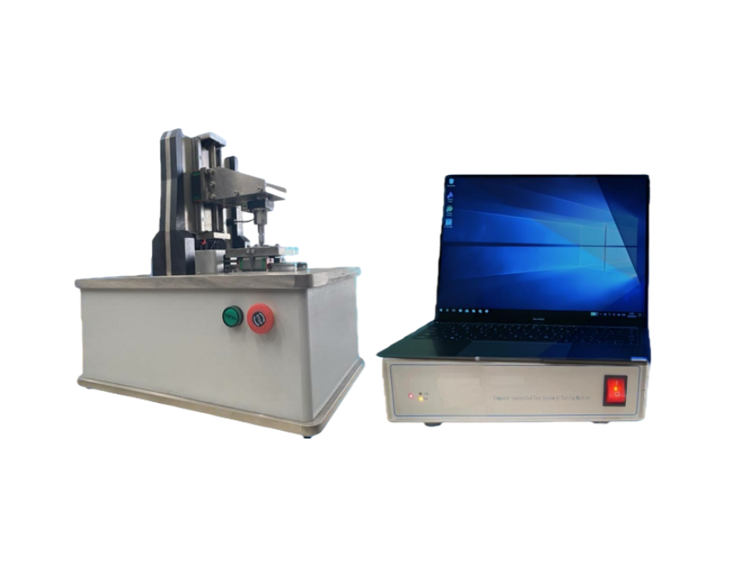

Multi-Functional Friction and Wear Tester

The Multi-Functional Friction and Wear Tester is a versatile instrument designed to evaluate the friction and wear performance of materials, surface coatings, and components. With support for a wide range of loads and rotational speeds, this tester can conduct both ball-on-disk and pin-on-disk tests. It complies with international testing standards such as GB, ISO, and ASTM.

This tester is computer-controlled for monitoring and automatically records essential parameters like friction coefficient, friction force, load, and torque, which are displayed in real-time in both data and graphical formats. An optional environmental control system allows for testing under adjustable temperature and atmosphere conditions.

Application

The Multi-Functional Friction and Wear Tester is ideal for a broad range of applications:

Material surface processing: Research and evaluation of surface treatments or coatings.

Material failure & reliability: Identifying wear and failure points for improved material design.

Quality control: Used in industrial product quality inspection and ensuring durability and performance.

Wide material compatibility: Suitable for testing materials, coatings, and component surfaces under various frictional conditions.

Standards

This instrument is compatible with multiple international testing standards:

(1) GB/T 3960 — Plastic Sliding Friction and Wear Test Methods

(2) GB/T 12444 — Metal Wear Test Methods

(3) GB/T 30732 — Tribological Testing Methods

(4) ISO 7148 — Guidelines for Selecting Friction and Wear Test Conditions

(5) ISO 11093-2 — Method for Friction and Wear Testing of Materials

(6) ASTM G99 — Pin-on-Disk Friction and Wear Test Method

(7) ASTM G133 — Linear Reciprocating Friction and Wear Test Method

(8) ASTM G77 — Block-on-Ring Friction and Wear Test Method

Note: Test parameters are customizable according to the specific standard being followed.

Technical Parameters

| Item | Specification |

|---|---|

| Test Load Range | 10–2000 g (accuracy ±1% F.S) |

| Test Speed | 5–2000 rpm (stepless adjustment) |

| Reciprocating Frequency | 0–20 Hz (optional module) |

| Reciprocating Stroke | 1–25 mm |

| X-axis Travel | 3–25 mm, adjustable |

| Z-axis Height | 0–100 mm, adjustable |

| Friction Diameter | Φ3–Φ50 mm |

| Lower Specimen Size | 10–60 mm, thickness 2–20 mm |

| Upper Specimen Size | Φ3–Φ6 mm, pin length 10–15 mm (customizable) |

| Friction Force Measurement Range | ≤20 N |

| Friction Coefficient Accuracy | 0.2% F.S |

| Heating Module Temperature | Room temperature–220°C |

| Friction Environment (Optional) | Stainless steel or PTFE chamber for liquid friction testing |

| Dimensions | 900×500×700 mm |

| Weight | 60 kg |

Product Features

Multiple Friction Pair Configurations: Supports ball-on-disk and pin-on-disk tests for various material combinations.

Real-Time Measurement: Displays friction coefficient, friction force, load, torque, and other parameters in real-time.

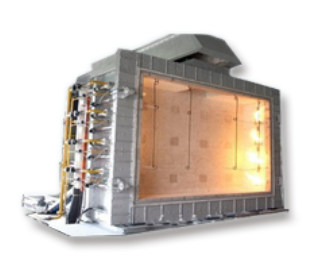

Adjustable Environmental Control: Allows testing under controlled temperature and atmosphere (optional module).

Wide Load and Speed Range: Offers flexibility for testing a variety of materials and surfaces.

Automatic Safety Shutdown: Ensures reliability with automatic protection in case of parameter overrun.

Modular Design: Includes optional reciprocating and rotary modules for extended testing flexibility.

High Precision: Friction coefficient accuracy up to 0.2% F.S for precise measurement.

Compact and User-Friendly: Easy to operate and setup, with a comprehensive accessory kit provided for convenience.

Accessories

Main Components:

Multi-functional friction and wear control system

LCD display and main unit

Tool kit, backup files, and user manual

Optional Modules:

Reciprocating Module

Sample Size: 8–35 × 8–60 × 1.5–12 mm

Stroke: 3–25 mm

Frequency: 0.5–20 Hz

Dry Friction Max Load: ≤100 N

Note: Stroke-frequency limits

2 Hz → ≤10 mm

10 Hz → ≤5 mm

30 Hz → ≤3 mm

Rotary Module

Sample Size: Φ10–Φ53 mm, thickness 2–10 mm

Rotation Radius: 3–20 mm

Test Speed: 10–1000 rpm, ±1 rpm

Note on Load-Speed Limits:

3000 rpm → ≤2 N

2000 rpm → ≤5 N

1000 rpm → ≤10 N

500 rpm → ≤20 N

200 rpm → ≤100 N

Test Procedures

Prepare the Sample: Mount the sample according to the chosen friction mode (ball-on-disk, pin-on-disk, etc.).

Set Parameters: Configure test parameters such as load, speed, stroke, frequency, temperature, and lubrication condition.

Start the Test: Initiate the test and monitor real-time results on the display. The system will record friction forces, torque, and temperature throughout the test.

Post-Test Analysis: Once the test is complete, use the software's post-processing features to analyze the data, export it in multiple formats (e.g., txt, xlsx), and generate reports.

Maintenance Information

Cleaning: Regularly clean friction surfaces to prevent buildup of wear particles or contamination.

Calibration: Calibrate the load and displacement sensors periodically to maintain accurate measurements.

Lubrication: Ensure lubrication channels are clean and replenish lubricants as needed for oil-lubricated tests.

Software Updates: Keep the software and firmware up to date for optimal functionality and feature enhancements.

System Checks: Periodically check the temperature control system and verify the stability of components to ensure reliable performance.

FAQ

What is this product?

The Multi-Functional Friction and Wear Tester is a highly flexible instrument for evaluating the friction and wear properties of materials, surface coatings, and components.

What is it used for?

It is used for research, quality control, and reliability testing of materials, coatings, and components in a wide range of industries.

Why is it important?

This tester helps assess the durability and performance of materials under friction and wear conditions, which is crucial for product development and quality assurance in manufacturing.

Which industries is it suitable for?

It is suitable for industries such as automotive, aerospace, metallurgy, materials science, and manufacturing.

What types of tests can it perform?

It can perform ball-on-disk, pin-on-disk, reciprocating, and rotary friction and wear tests, among others.

Leave Message Get Price