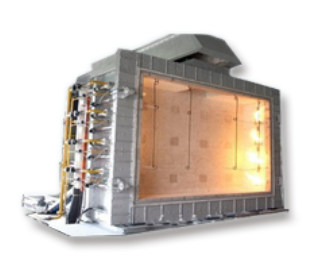

PV Module Testing Equipment – UV Aging Test Chamber

The UV Aging Test Chamber for photovoltaic (PV) modules is designed to simulate long-term exposure to outdoor sunlight, specifically the destructive effects of ultraviolet (UV) radiation. By replicating months or years of outdoor UV aging in just a few days or weeks, this chamber allows for rapid evaluation of material resistance and durability. It complies with international testing standards such as GB, ISO, and ASTM.

Application

This chamber is primarily used to assess the UV aging resistance of various PV module components, including:

Encapsulant

Backsheet

Glass

Junction Box Materials

It is suitable for use in research laboratories, PV module manufacturers, and quality control facilities, where it plays a crucial role in ensuring the longevity and performance of solar modules.

Standards

The UV Aging Test Chamber is designed to comply with international standards for UV aging testing, such as:

ISO 9001 (Quality management)

ASTM G154 (Standard Practice for Operating Fluorescent Light Apparatus for UV Exposure of Nonmetallic Materials)

IEC 61215 (Test for the performance of PV modules)

Note: Specific test parameters and conditions are set according to the standard being followed.

Technical Parameters

| Item | Specification |

|---|---|

| Lamp Brand | Osram |

| Lamp Lifespan | Approximately 2000 hours |

| Single Lamp Power | Approximately 2 kW |

| UV Wavelength Range | UVA 320–400 nm, UVB 280–320 nm |

| UVB Relative Energy | 3–10% of total UV energy per lamp |

| Irradiance | 150–250 W/m² (280–400 nm) |

| Irradiance Uniformity | Better than ±15% |

| Sample Surface Temperature | 60 ± 2 °C |

| Internal Chamber Temperature | 30–90 °C, adjustable |

| Temperature Resolution | 0.1 °C |

| Ozone Generation | Negligible |

| Illumination Method | Top illumination |

| Irradiance & Irradiation Dose Notes | UVB (280–320 nm) accounts for 3–10% of total irradiance in the 280–400 nm range according to IEC 61215-2 |

Product Features

High-Quality Lamps: Utilizes Osram lamps with a lifespan of up to 2000 hours, providing long-lasting, efficient UV radiation.

Wide Irradiation Area: The chamber covers an area of 2800 mm × 2800 mm, allowing for larger samples and reducing the number of lamps required.

Energy Efficiency: Achieves large irradiation areas with fewer lamps, lowering operational costs and extending lamp life.

UV Blocking & Insulated Construction: The cabinet is made of UV-blocking, insulated, and environmentally-friendly materials.

Dual-Door Design: Separates the lamp system and cooling system in the upper compartment from the sample platform in the lower compartment, ensuring safety and efficient operation.

Precise Monitoring: Equipped with fiber sensors for UVA and UVB for precise measurement of UV exposure.

Real-Time Data Monitoring: The chamber features an industrial touch screen and PLC controller that automatically controls temperature, irradiance, irradiation dose, and test duration.

Wind-Cooled Temperature Control: Maintains sample surface temperature at 60 ± 2 °C, with internal chamber temperature adjustable from 30°C to 90°C.

Safety Features: The system automatically turns off lamps and sounds an alarm when temperature limits are exceeded.

Data Export: Test data, including temperature and irradiance curves, can be stored and exported for comprehensive reporting.

Real-Time Monitoring: Provides real-time temperature and irradiance curves, ensuring that results are continuously monitored and can be analyzed instantly.

Accessories

Main Unit: UV Aging Test Chamber with a built-in control system.

Lamps: High-performance Osram UV lamps for optimal testing results.

Fiber Sensors: Dedicated UVA and UVB fiber sensors for precise data collection.

Industrial Touch Screen: For real-time monitoring and graphical display.

PLC Programmable Controller: Automatically controls test parameters.

Backup Files: Includes essential files for system operation and troubleshooting.

User Manual: Comprehensive guide for easy operation and setup.

Test Procedures

Sample Preparation: Place the PV module or component (e.g., encapsulant, backsheet) inside the test chamber on the designated sample platform.

Parameter Setup: Configure the test parameters, including irradiance, temperature, and duration, based on the specific material and test requirements.

Start the Test: Activate the test via the industrial touch screen. The system will automatically control and monitor the parameters, including irradiance and temperature.

Monitoring: Observe the real-time graphical display of temperature, irradiance, and test duration during the test. Data is continuously recorded for further analysis.

Post-Test Analysis: After the test, review the results, including irradiance curves and temperature profiles, and export data for detailed analysis and reporting.

Maintenance Information

Lamp Replacement: Ensure regular inspection of the lamps and replace them when their lifespan reaches 2000 hours to maintain consistent testing performance.

Cleaning: Regularly clean the interior and exterior of the chamber to remove dust and debris. Keep the UV-blocking materials and reflectors free from contamination.

Calibration: Periodically calibrate the UV sensors and temperature control system to ensure accurate and reliable testing.

Software Updates: Update the software to ensure that the system is operating with the latest features and optimizations.

Safety Checks: Perform regular checks on the safety systems, including the alarm functionality and automatic lamp shutdown, to ensure they are working properly.

FAQ

What is this product?

The UV Aging Test Chamber simulates the effects of long-term UV exposure on photovoltaic (PV) modules and components to evaluate their durability and resistance.

What is it used for?

It is used to test the UV aging resistance of materials such as PV module encapsulants, backsheets, glass, and junction boxes, helping to predict long-term performance.

Why is it important?

UV aging tests are crucial for assessing how PV modules and materials will perform in real-world outdoor environments, ensuring the durability and longevity of solar panels.

Which industries is it suitable for?

This chamber is primarily used in the photovoltaic (PV) industry, including module manufacturers, research labs, and quality control facilities.

What types of tests can it perform?

It performs UV aging tests under controlled conditions, including both UVA and UVB radiation exposure, simulating real-world sunlight exposure for PV materials.

Leave Message Get Price