How does a fabric tensile testing machine work?

The fabric tensile testing machine is an instrument used to test the mechanical properties of fabrics such as tensile, compression, peeling and tearing, which is widely used in textiles, garments, composite materials and other fields.

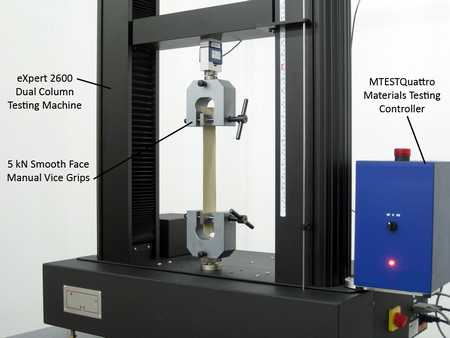

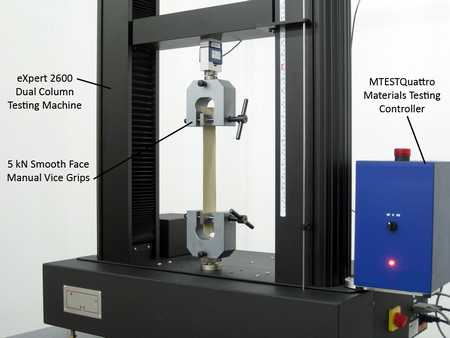

The working principle of fabric tensile testing machine is to control the load and deformation by electronic or hydraulic system, clamp the fabric sample between two jaws, and then apply tension or pressure in a certain speed and way until the sample breaks or reaches the preset deformation amount. During the testing process, the instrument can display and record the load, deformation, time and other data in real time, and draw the stress-strain curve, from which the strength, modulus, elongation and other performance indexes of the fabric can be calculated.

There are various types and specifications of fabric tensile testing machine, and different test methods and fixtures can be selected according to different testing needs and standards. For example, the unwinding test and the grip test are two common fabric tensile testing methods, which are suitable for testing the breaking strength and grip strength of fabric respectively. Unwinding test is to cut the fabric along the warp and weft into a certain width of the strip sample, and then the two ends of the clamp in the jaws, with a certain speed of stretching to break. The grip test is to cut the fabric sample into rectangular samples of certain size along the warp and weft, and then clamp its middle part in the jaws and stretch it at a certain speed until it breaks. The test results of the two methods are different because the split test only considers the strength of a single yarn, while the grab test considers the structure and friction between the yarns.

The fabric tensile testing machine is an important textile testing equipment, which can provide reliable data support for textile design, production and quality control. By conducting tensile test on fabrics, the durability, comfort, safety and other properties of fabrics can be evaluated, thus improving the use and satisfaction of fabrics.

2023-04-27 11:14