Quality assurance for the textile industry - textile testing equipment recommendations

Textile testing equipment typically includes tests for mechanical properties, surface texture, colour fastness, UV resistance, stain resistance, water resistance, abrasion resistance and fire resistance. The assessment of the quality of textile fabrics is a common concern for textile manufacturers and consumers alike. Here are five commonly used textile fabric testing devices.

Linear densitometers

A wire density meter is an instrument used to measure the density of a fabric and is able to measure the amount and density of yarn per unit length and is often used to test textile quality.

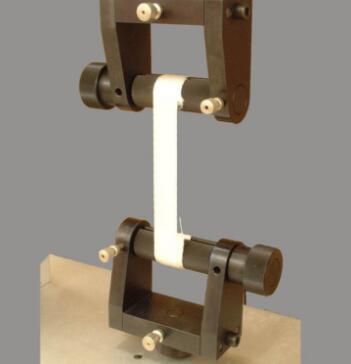

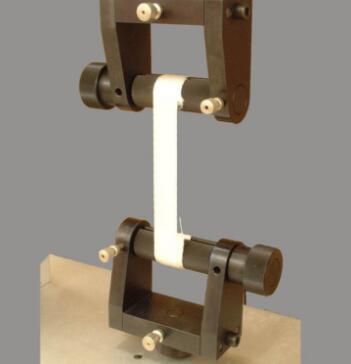

Tear strength testers

A tear strength tester is a piece of equipment used to measure the strength of a fabric against tearing. This equipment can be used to test the strength and durability of fabrics.

Colour fastness testers

A colour fastness tester uses a special device to measure the fastness of fabrics to dyeing. This equipment is typically used to test the colour fastness of fabrics, particularly under a variety of conditions such as exposure to water, sunlight, rubbing and washing.

Tensile testers

A tensile tester is a device used to measure the tensile strength and elasticity of a fabric when subjected to a force. This equipment can be used to test the strength, stretch and shrinkage properties of fabrics.

Abrasion testing machine

Used to test the abrasion resistance and durability of fabrics in use. This equipment can simulate realistic conditions of use, such as sofa cushions, bedding, car seats, etc.

For textile manufacturers and consumers, these commonly used textile fabric testing machines are essential tools to help assess the quality, performance and durability of textiles.

2023-03-10 11:16