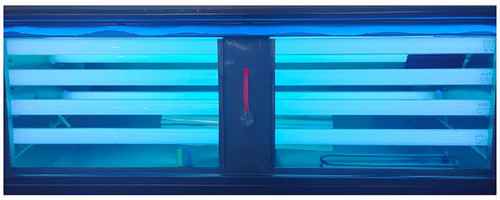

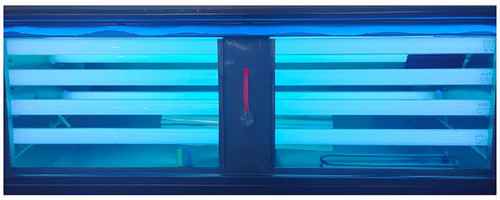

UV Accelerated Weather Tester irradiance uniformity

Many equipment manufacturers claim that the "irradiance uniformity" of their UV Accelerated Weather Tester is 4%, but they tend to downplay the actual meaning of 4%. Strictly speaking, the correct expression is either 96% uniformity or 4% nonuniformity. Moreover, the irradiance uniformity cannot be said to be the uniformity of the entire test space, or even the uniformity of one side of the sample rack. It can only be said at 6.35 × On the area of 9.53 square centimeters, the irradiance nonuniformity is 4%. Many customers often fail to understand this statement and are misled.

In addition, the uniformity of irradiance on the surface of a single sample has little effect on the evaluation of physical properties (such as gloss or color). The reason is that when testing, it is usually evaluated from the center of the sample rather than the edge of the sample.

What is the UV Accelerated Weathering Tester's irradiance uniformity?

There is no doubt that the UV Accelerated Weathering Tester also meets the uniformity of irradiance claimed by other equipment manufacturers, and we can state it more clearly: if you exclude the sample holders at the edges, we can provide an overall uniformity of irradiance of >90%.

Due to the physical and geometrical limitations of the chamber, the irradiance of the sample holders at the edges is lower than that of the samples in the middle of the chamber in all UV Accelerated Weathering Testers. The fluorescent UV lamp emits light over its entire length. The sample receives most of its light from the part of the lamp, but is also exposed to light from the parts of the lamp to the left and right of the sample. The sample on the left side, however, is not exposed to light from the left side because the lamp does not extend to the left. Similarly, the sample on the right side of the UV accelerated ageing tester will not be exposed to the light on its right side.

Which position should be selected for the results assessment?

Although the irradiation levels are slightly lower on both sides, our recommendation is that all samples can be used for the results evaluation, but it is recommended that the sample position is changed during the test. If the customer does not wish to reposition the sample or requires irradiance uniformity of >90% at all positions, then they may choose to leave the end clips blank.

Temperature Uniformity Considerations

With proper installation and test piece mounting, the temperature uniformity of the QUV UV Accelerated Weathering Tester is very good. It is very important that the customer avoid any gaps at the ends of the test piece or between test pieces that would allow air to rush out of the chamber, cooling adjacent specimens.

UV accelerated aging test chamber sample installation

For this reason, the research and development engineer of Shanghai Qianshi Precision Electromechanical Technology Co., Ltd. said that when asking about the uniformity of UV Accelerated Weathering Tester, it is necessary to define the problem. Are you asking about irradiance uniformity or temperature uniformity? What is the range for measuring uniformity? We prefer to use the uniformity of irradiance across the UV Accelerated Weathering Tester (in UV Accelerated Weathering Tester Medium irradiance uniformity >90%) as a reference.

The laws of physics and geometry limit the irradiance at the end of the lamp. We propose to overcome this limitation by using specimen repositioning, which also improves water spray and temperature uniformity. Of course, it is important to mount the sample correctly.

2023-02-21 15:43