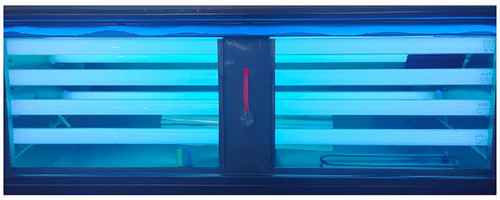

QINSUN UV Aging Test Chamber main parameters and experimental principle

UV Aging Test Chamber is another kind of light aging test equipment that simulates light, which mainly simulates the ultraviolet light in sunlight. At the same time, it can also reproduce the damage caused by rain and dew. The equipment performs the test by exposing the material to be tested to a controlled interactive cycle of sunlight and moisture, while raising the temperature. The equipment uses UV fluorescent lamps to simulate sunlight, while the effects of moisture can also be simulated by condensation or spraying.

In just a few days or weeks, the UV Aging Test Chamber can reproduce the damage that takes months or years outdoors. The damage caused mainly includes fading, discoloration, loss of brightness, chalking, cracking, blurring, embrittlement, loss of strength and oxidation. The test data provided by the equipment can be extremely helpful in selecting new materials, improving existing materials, or evaluating changes in composition that affect the durability of products. The equipment can be an excellent predictor of the changes that a product will experience outdoors.

Although ultraviolet (UV) light accounts for only 5% of sunlight, it is the primary light factor that causes outdoor product durability to deteriorate. This is because the photochemical effects of sunlight increase as the wavelength decreases. Therefore, when simulating the damaging effects of sunlight on the physical properties of materials, it is not necessary to reproduce the entire sunlight spectrum. In most cases, only short wavelengths of UV light need to be simulated. The reason why UV lamps are used in accelerated UV weathering testers is that they are more stable than other lamps and can reproduce the test results better. The use of fluorescent UV lamps is the way to simulate the effects of sunlight on physical properties such as brightness loss, cracking, peeling, and other aspects. There are several different UV lamps to choose from. Most of these UV lamps produce mainly ultraviolet light, rather than visible and infrared light. The main difference between the lamps is reflected in the difference in the total UV energy they produce in their respective wavelength ranges. Different lamps will produce different test results.

UVA-340 is a good choice for simulating the sun's UV rays

UVA-340 can extremely well simulate the sunlight spectrum in the critical short-wave wavelength range, i.e., the wavelength range of 295-360 nm. UVA-340 produces only the spectrum of UV wavelengths that can be found in sunlight.

UVB-313 for large degree of accelerated testing

UVB-313 can provide test results very quickly. The short wavelengths of UV they use are more intense than the UV light waves typically found on Earth today. Although these much shorter than natural wavelengths of UV light can accelerate the test to a large extent, it can also cause inconsistent and actual degradation damage to certain materials.

The standard definition of a fluorescent UV lamp emitting less than 300nm light energy than 2% of the total output light energy, usually called UVA lamps; emitting less than 300nm light energy than 10% of the total output light energy of a fluorescent UV lamp, usually called UVB lamps;

UVA wavelength range is 315-400nm; UVB wavelength range is 280-315nm;

Materials outdoors can be exposed to moisture for up to 12 hours per day, and research has shown that the main cause of this outdoor moisture is dew, not rain. The UV accelerated weathering tester simulates the effects of outdoor moisture through a series of unique condensation principles. In the condensation loop of the equipment, a water reservoir is located at the bottom of the chamber and is heated to produce water vapor. The hot steam maintains the relative humidity inside the chamber at 100% and maintains a relatively high temperature. The design of the product ensures that the test specimen actually forms the side wall of the chamber so that the back of the specimen is exposed to the ambient room air. The cooling effect of the room air causes the surface temperature of the specimen to drop to a level several degrees below the steam temperature. This temperature difference results in the presence of liquid water condensed on the surface of the specimen throughout the condensation cycle. This condensation product is very stable pure distilled water. This pure water improves the reproducibility of the test, while avoiding the problem of water damage.

Since outdoor exposure to moisture can last up to 12 hours per day, the moisture cycle of the UV accelerated weathering tester typically lasts several hours. We recommend that each condensation cycle last at least 4 hours. Note that UV exposure and condensation exposure in the equipment are done separately and are consistent with actual climatic conditions.

For some applications, water spraying can better simulate the end-use environmental conditions. Water spraying is extremely useful in simulating mechanical erosion due to drastic temperature changes and due to rainfall. The UV accelerated weathering tester/spray type is specifically designed to reproduce such conditions.

As a result of frequent rainfall, the coating layers of wood, including paints and stains, can erode accordingly. Studies with the UV Aging Test Chamber have shown that this rain action washes away the anti-degradation coating layer from the surface of the material, thus exposing the material itself directly to the damaging effects of UV and moisture. This process can be repeated many times, resulting in a material degradation phenomenon that cannot be reproduced by condensation alone.

2022-09-01 10:45

- Related News

The importance of battery internal resistance testing in the battery manufacturi

Application and structural principle of high and low temperature test chamber

Application of Small Coating Machine in Polyimide Slurry

Principles and selection methods of laboratory incubators

Evaluation of Moisture Absorption and Rapid Drying Performance of Textiles by Na

Liquid Moisture Management Tester

Paper ring compression strength tester standards