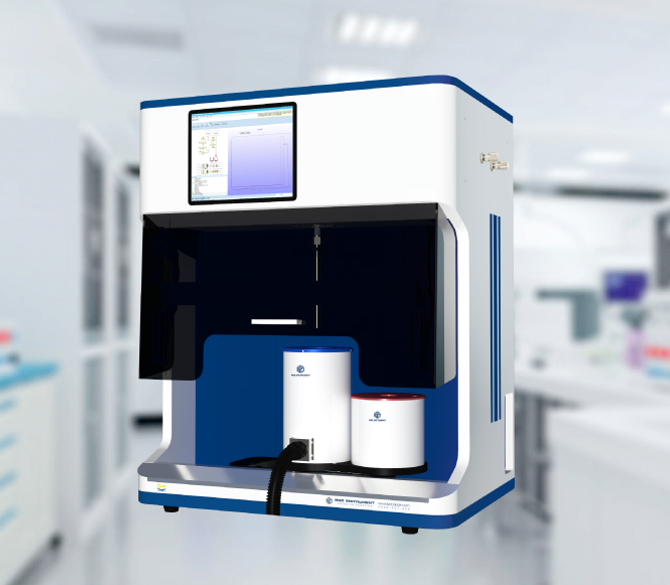

STD-PH Series High Pressure Gas Sorption Analyzer

STD-PH Series High Pressure Gas Sorption Analyzer

The PH Series high-temperature and high-pressure gas adsorption instruments provide fully automated high-pressure gas adsorption and desorption isotherm testing, covering applications such as shale gas, coalbed methane, and hydrogen storage. The series includes various models, including standard configurations (0-20 MPa), ultra-high-pressure configurations (0-50 MPa, 0-69 MPa), full-oil-bath ultra-high-pressure configurations, constant-pressure adsorption rate testing, overpressure high-pressure testing, and multi-component selective adsorption. These models meet the needs of adsorption performance research at various pressures and temperatures, ensuring high accuracy and safety.

Test Principle

◆ After the sample is placed in the sample tube, an inert calibration gas (such as helium) is first introduced to calibrate the sample volume and the remaining free space (dead volume) in the sample tube. A predetermined amount of adsorbate gas is then introduced into the sample tube (gas injection). When adsorption equilibrium is reached, the software automatically records the adsorption amount at that pressure. This process is then repeated until the desired maximum pressure is reached. Plotting the adsorption amount against the pressure value yields the adsorption isotherm.

◆ For some samples, the adsorption capacity varies significantly at different temperatures. In this case, we can test the changes in gas adsorption at different temperatures based on the user's actual needs.

◆ For all these complex operations, the BSD-PH series high-temperature and high-pressure gas adsorption analyzer is fully automated, automatically processing complex data models to provide an evaluation of the sample's high-temperature and high-pressure adsorption performance for the adsorbate!

Operation Guide

Preparation: Ensure a safe laboratory environment and check that the power and gas sources of the high-pressure adsorption analyzer are functioning properly. Prepare the required sample, adsorption gas, and standard gas according to experimental requirements.

Sample Processing: Pre-treat the sample to be tested, such as grinding, screening, and drying, to achieve uniform particle size and shape. Ensuring sample purity and loading quality are crucial to the accuracy of the results.

Sample Loading: Load the pre-treated sample into the sample loading chamber of the high-pressure adsorption analyzer, ensuring close contact between the sample and the instrument, with no visible gaps. Adjust the position and angle of the sample well according to the instrument's operating instructions to ensure uniform gas contact with the sample.

Setting Experimental Parameters: Based on the experimental requirements and sample characteristics, set appropriate experimental parameters, such as temperature, pressure range, and adsorbed gas type. These parameters should be selected based on the sample characteristics and test objectives, and should be set according to the instrument operating manual.

Conducting the Adsorption Experiment: Start the high-pressure adsorption instrument, allow the gas to gradually contact the sample, and maintain adsorption for a specified time. Record the pressure change during the adsorption process according to the set adsorption time, and monitor the adsorption amount in real time. During the experiment, carefully observe the instrument's operating status to ensure safe operation.

Data Processing and Analysis: After the experiment, export the experimental data and perform data processing and analysis. Use appropriate software or algorithms to process the adsorption data, such as calculating the adsorption amount and plotting the adsorption isotherm. Based on the experimental results, evaluate the sample's adsorption performance and conduct further research and analysis.

Experimental Techniques

Careful Sample Preparation: Sample pretreatment and loading procedures significantly influence experimental results. Therefore, ensure proper sample preparation before conducting the experiment to obtain accurate results.

Appropriate Parameter Selection: When setting experimental parameters, consider the sample characteristics and test objectives. Also, follow the recommendations in the instrument's operating manual to obtain reliable results.

Pay attention to experimental safety: When using a high-pressure adsorption instrument, follow relevant safety operating procedures to ensure the personal safety of experimenters and the proper operation of the equipment. During the experiment, carefully observe the instrument's operating status to promptly identify and address any abnormalities.

Ensure accurate data analysis: During data processing and analysis, select appropriate adsorption models and calculation methods, and pay attention to the interpretation and evaluation of results. Combined analysis with other experimental data provides more comprehensive and accurate information.

By following the above operating guidelines and experimental techniques, you can better utilize your high-pressure adsorption instrument for experimental research and obtain accurate and reliable results.

2025-08-19 14:39

- Related News

Tile Abrasion Tester Operating Guide

STD-PH Series High Pressure Gas Sorption Analyzer

Maintenance Guide for Washing Color Fastness Tester

Warm-Body Sweat Manikin: A New Tool for Clothing Thermal Comfort Testing

Double-station Taber abrasion tester