How is the perspiration fastness test conducted?

The Perspiration Fastness Test, often conducted according to ISO 105-E04 standard, assesses a textile's resistance to color change when exposed to artificial perspiration. Here's a general overview of how the test is conducted:

Perspiration Fastness Test Procedure:

Materials and Equipment:

- Specimens: Cut representative samples of the textile to be tested.

- Artificial Perspiration Solution: Prepare a standardized artificial perspiration solution as per the ISO guidelines.

- Stainless Steel or Glass Containers: Use containers to hold the artificial perspiration solution.

- White and Grey Reference Fabrics: Use these fabrics for color comparison.

Test Steps:

Sample Conditioning:

- Condition the textile specimens in a standard atmosphere to ensure uniform moisture content.

Preparation of Artificial Perspiration:

- Prepare the artificial perspiration solution according to the specified ISO guidelines. This solution should mimic the composition of human sweat.

Application of Perspiration:

- Apply the artificial perspiration solution to the textile specimens. The application can be through dipping, spraying, or other methods depending on the specific requirements.

Drying:

- Allow the specimens to dry completely, either at room temperature or using specified drying conditions.

Aging:

- Age the specimens by placing them in a controlled environment for a specified period. This environment may include elevated temperature and humidity conditions to simulate realistic wear.

Evaluation:

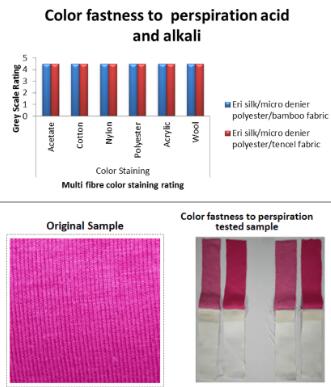

- After the aging period, visually assess the textile specimens for any color change, staining, or other undesirable effects caused by the artificial perspiration.

- Compare the tested specimens with white and grey reference fabrics to determine the degree of color change.

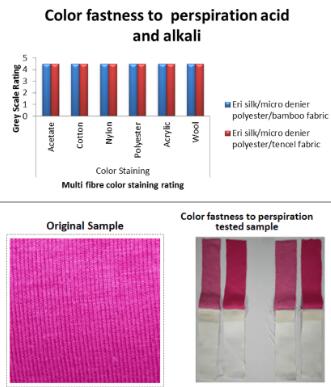

Grading:

- Grade the test results based on the ISO standard criteria, which typically include a scale ranging from 1 (severe staining or color change) to 5 (no staining or color change).

Documentation:

- Record the test conditions, observations, and results for future reference.

Considerations:

- Follow the specific guidelines outlined in ISO 105-E04 for the details of preparation, application, and assessment procedures.

- Conduct the test under controlled laboratory conditions to ensure repeatability and accuracy.

- Perform the test on multiple specimens to account for variations within the textile material.

The Perspiration Fastness Test provides valuable information about a textile's ability to resist color changes caused by perspiration, ensuring the material meets quality standards for various applications, including apparel and active wear.

2023-11-21 15:15