Secret weapon to improve textile production efficiency: Yarn length measuring instrument!

The textile industry has always focused on improving production efficiency and product quality. In this competitive market, Yarn length measuring Instrument is a secret weapon for productivity. This article will describe the working principle, advantages and important impact on the efficiency of the textile production.

The working principle of Yarn length measuring Instrument

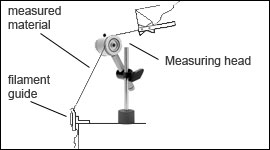

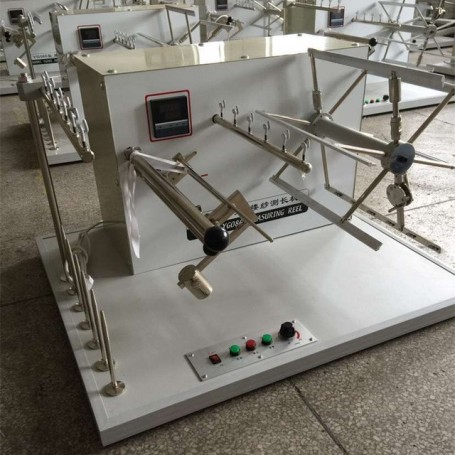

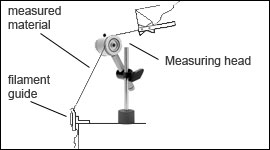

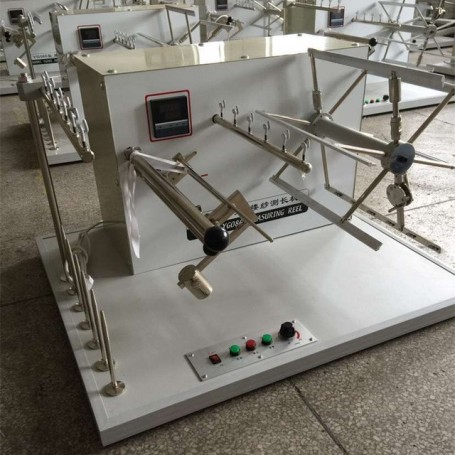

Yarn length measuring Instrument helps textile companies achieve more accurate product control and production process monitoring by precisely measuring yarn length. Its working principle is based on the yarn's length calculated by measuring the speed of the device over a unit time. Common Yarn length measuring Instrument typically uses photoelectric or mechanical measurement principles, through the yarn to measure device contact or reflection of photoelectric sensors, converts yarn length into electrical or mechanical displacement, and processes and displays through the instrument.

The advantages of Yarn length measuring Instrument

Improve productivity: Yarn length measuring Instrument quickly and accurately measures yarn length, avoiding uncertainty and time costs for traditional hand-measured measurements. It can achieve automated measurement, save human resources and improve production efficiency.

2. Important tools for quality control: yarn length is an important indicator of influencing textile quality. By using Yarn length measuring Instrument, textile companies can detect yarn length differences in time, accurately control product quality, and provide more stable and consistent textiles.

Data Recording and Analysis: Yarn length measuring Instrument can record measurements in real time and save them in a database for follow-up analysis and statistics. By analyzing yarn length data, you can understand yarn output, spinning equipment operation condition and process parameters adjustment requirements, so as to optimize the production process.

Traceability and quality assurance: Yarn length measuring Instrument provides traceability and traceability of yarn length. By recording the length data of each yarn, we can quickly find out the abnormalities in the production process, conduct problem investigation and quality traceability, and ensure the quality stability of the product.

Effect of Yarn length measuring Instrument on textile production efficiency

1. Reduce waste rate: the stability of yarn length directly affects the yield and quality of textiles. By using Yarn length measuring Instrument, you can accurately control yarn length, reduce scrap rate and improve product quality.

Optimizing equipment utilization: Yarn length measuring instament can monitor the working condition and output of the equipment in real time, helping enterprises to optimize equipment operation, avoiding downtime and inefficient production due to the lack of yarn length.

3. Improve the accuracy of production plan: Yarn length measuring Instrument can provide timely yarn length data to help enterprises accurately grasp yarn yield and quality, provide accurate reference for production plans and materials purchase, and avoid production due to the yarn length does not meet production requirements

2023-10-17 11:26