Evaluation of Factors Affecting the Abrasion Resistance of Textile Garments

The abrasion resistance of textile garments is their ability to withstand the effects of external forces such as friction, stretching and abrasion during use. Evaluating the factors affecting the abrasion resistance of textile garments is an important step in ensuring product quality and performance. Some of the common influencing factors are described below:

1. Fibre type:

Different types of fibres have different abrasion resistance properties. In general, natural fibres such as cotton and silk are relatively weak, while synthetic fibres such as polyester and nylon are usually more resistant. It is important to assess the effect of the type of fibre used in a textile on its abrasion resistance.

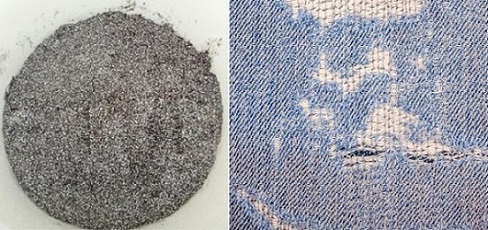

2. Fibre structure:

The structure of the fibres and the way the textile is woven affects its abrasion resistance. For example, a tighter weave is usually more resistant to abrasion than a looser weave. It is necessary to evaluate the effect of factors such as weave structure, yarn density and yarn gaps on the abrasion resistance of a textile.

3. Surface treatment:

Textiles may undergo some special surface treatments to improve their abrasion resistance. For example, a coating treatment creates a protective coating that provides additional abrasion protection. It is important to assess whether the textile has undergone a special surface treatment and the effect of that treatment on the abrasion resistance.

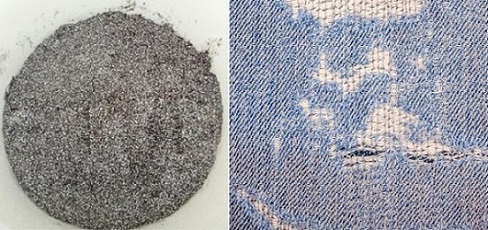

4. Fabric structure:

In addition to the fibres themselves, the structure of the fabric also affects the abrasion resistance. For example, different fabric structures such as plain, twill and satin produce different abrasion resistance. Evaluating the effect of fabric structure on abrasion resistance and selecting the right fabric structure for the application is key.

5. Environmental conditions:

The abrasion resistance of textiles may vary under different environmental conditions. For example, wet environments and high temperatures may have a negative impact on the abrasion resistance of textiles. It is necessary to evaluate the abrasion resistance of textiles under specific environmental conditions.

6. Mode of use:

The way in which textiles are used can also have an effect on their abrasion resistance. For example, frequent rubbing and stretching may cause textiles to wear out more quickly. It is important to assess the abrasion resistance of textiles in a particular way of use.

7. Quality standards:

Depending on the textile use, there may be a number of relevant quality standards and test methods for assessing the abrasion resistance. It is important to assess whether the textile complies with the relevant quality standards and to carry out the corresponding tests.

In summary, a number of factors need to be taken into account when assessing the abrasion resistance of textile garments, including fibre type, fibre structure, surface treatment, fabric structure, environmental conditions, mode of use and quality standards. Taking these factors into account can help to select textile garments with good abrasion resistance.

2023-10-10 10:32