What is the pilling test method ASTM d3512?

ASTM D3512 is a standard published by the American Society for Testing and Materials (ASTM) to evaluate the napping and pilling properties of fabrics. This standard covers two main test methods, the Martindale method and the random fluff method.

1. Martindale method: This is a commonly used fuzzing and pilling test method that simulates the wear and tear of fabrics in daily use. This test method uses a Martindale nap tester where a fabric sample is placed under the rubbing head in contact with a rubbing platform with specified surface characteristics. In the specified time, the fabric and the friction platform generate relative motion, simulating the wear and friction of the fabric surface. The fabric samples were then evaluated using the evaluation criteria and scored for shedding of hairiness and degree of pilling.

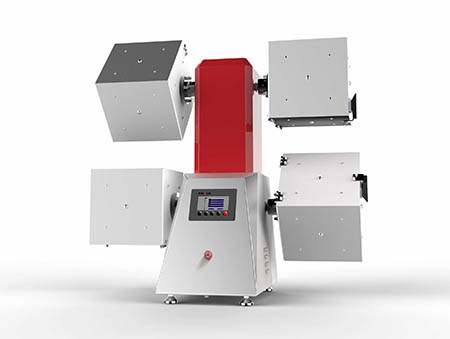

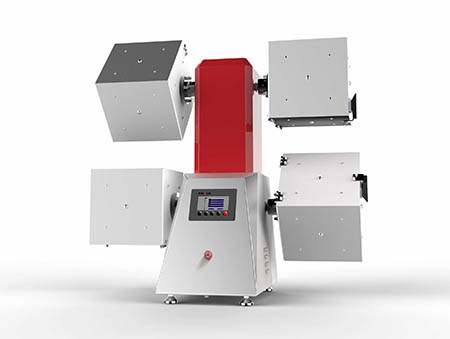

2. Random fluffing method: This method uses a random fluffing instrument, by placing a fabric sample and a friction body (such as a sphere) in a rotating test chamber, so that the samples rub and collide with each other. The random fuzzing method simulates the wear and friction encountered by fabrics in real use, producing hairiness and pilling during testing. Fabric samples are evaluated and scored according to the degree of hairiness and pilling.

The ASTM D3512 standard establishes the general principles of fuzzing and pilling testing, sample preparation, requirements for testing equipment, testing conditions and evaluation methods. The purpose of this standard is to provide a standardized method to compare the differences in fuzzing and pilling properties of different fabrics, to evaluate the durability and quality of fabrics, and to help manufacturers improve the design and treatment of fabrics to reduce fuzzing and pilling. Pilling phenomenon.

In practical application, the ASTM D3512 standard is one of the very important standards in the fabric industry, which is used to determine the fuzzing and pilling properties of fabrics under normal use conditions and to ensure that fabrics meet specific quality and performance requirements.

2023-07-31 12:21