What are the different types of rubber testing equipment?

Rubber test equipment is a key tool used for performance testing and quality control of rubber materials. Following are some common types of rubber test equipment:

1. Rubber hardness tester:

Rubber hardness testers are used to measure the hardness of rubber materials and common types include Durometer and Rockwell Hardness Tester. These devices determine the hardness of a rubber material by measuring how much it deforms under force.

2. Tensile Testing Machine:

Tensile testing machines are used to measure the tensile properties of rubber materials, including indicators such as maximum tensile strength, elongation at break, and modulus of elasticity. The machine evaluates the mechanical properties of rubber materials by applying force and measuring the deformation of the sample.

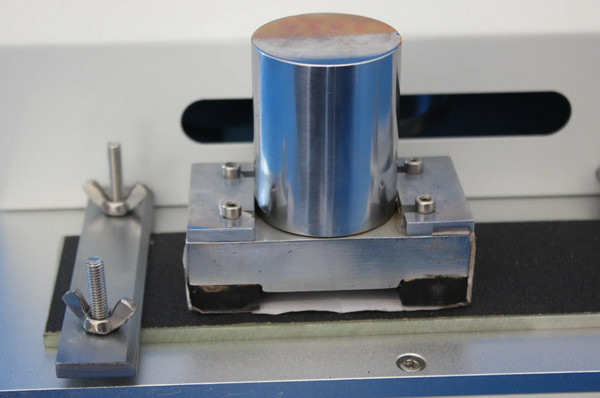

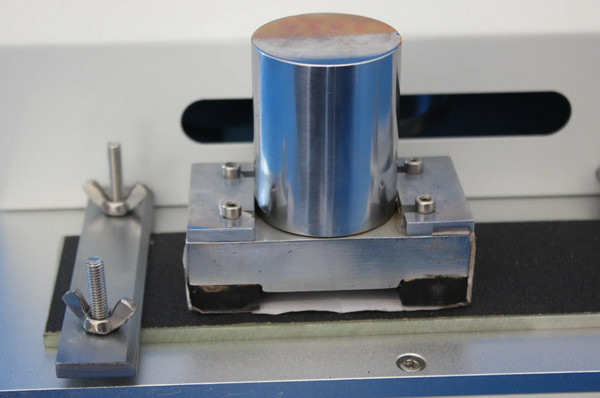

3. Abrasion Tester:

An abrasion tester is used to evaluate the abrasion resistance of a rubber material, usually by applying a force in a sliding or rolling manner and measuring the amount of abrasion of the material. This equipment simulates the wear and tear of a rubber product under actual conditions of use.

4. compression permanent deformation tester:

The compression permanent deformation tester is used to evaluate the ability of a rubber material to recover after being subjected to pressure. This equipment applies a certain pressure and measures the degree of recovery of the rubber material after the pressure is relieved to determine its compression permanent deformation performance.

5. Fatigue Testing Machine:

Fatigue testing machine is used to simulate the fatigue performance of rubber products in long-term use. The equipment evaluates the durability of rubber materials by applying cyclic loads and measuring the deformation, damage or failure of the material.

6. Tensile Relaxation Tester:

Tensile relaxation testers are used to evaluate the tensile relaxation properties of rubber materials. The device applies a constant strain or stress and measures the change in stress or strain of the rubber material over time to assess the stability of its properties under long-term stretching.

7. High and low temperature test chamber:

High and low temperature test chambers are used to simulate the performance of rubber products under extreme temperature conditions. The equipment can provide high or low temperature environment, and measure the physical and mechanical properties of rubber materials at different temperatures change.

8. Densitometer:

Densitometers are used to measure the density of rubber materials to assess their quality and composition. The equipment measures the volume and mass of the rubber material by immersion or buoyancy method to calculate its density value.

9. Vulcanizer:

Vulcanizers are used for controlling and monitoring the vulcanization process of rubber materials. The device controls parameters such as temperature, pressure and time to obtain the desired physical properties of the rubber material during vulcanization.

10. Dynamic Mechanical Analyzer (DMA):

DMA is used to evaluate the dynamic mechanical properties of rubber materials. This equipment measures parameters such as modulus of elasticity, damping characteristics and loss factor of rubber materials under different temperature, frequency and strain conditions.

These are some of the common types of rubber test equipment used to evaluate the mechanical, physical, durability and thermal properties of rubber materials. Different types of equipment can be selected and used as needed to meet specific testing requirements and quality control standards.

2023-07-12 13:29