Oxygen Index Test for Polymers: Assessing Flame Retardancy

The Polymers Oxygen Index Test is a method used to evaluate the flame retardancy of polymeric materials. Oxygen index refers to the minimum oxygen concentration that allows materials to spontaneously ignite and maintain combustion in a mixed gas environment of oxygen and nitrogen. A higher oxygen index indicates that the material has better flame retardant properties. The following are the steps of a common polymer oxygen index test method:

1. Sample preparation:

a. Select a polymer sample that meets the test requirements, and cut the sample into an appropriate size and shape according to the standard requirements. Typically, the size of the sample is 150mm x 6mm x 3mm and the shape is rectangular.

b. According to the need, carry out necessary surface treatment on the sample, such as removing dirt, oxide layer, etc.

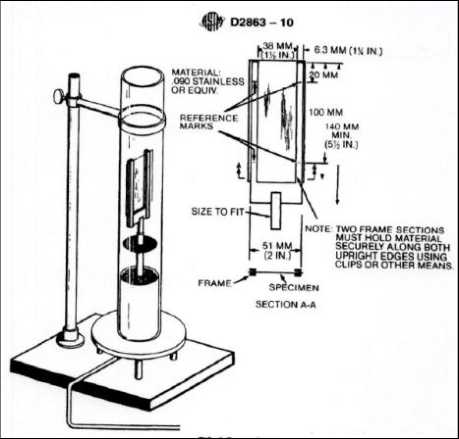

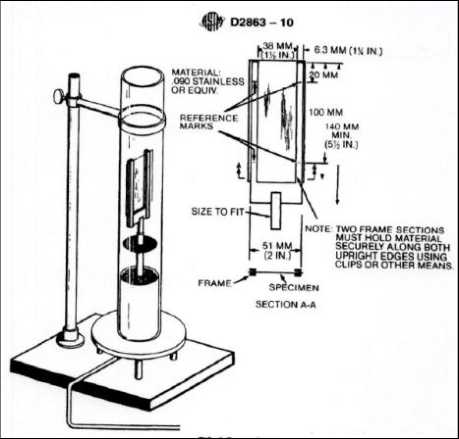

2. Sample installation:

a. Fix the sample on the test device, making sure that the surface of the sample is flat and in good contact with the clamps of the test device.

b. Make sure there is no gap between the edge of the sample and the clamp to prevent gas leakage.

3. Preheating:

a. Turn on the oxygen index tester and set the temperature controller to the test temperature (typically 23°C).

b. Wait for the tester to reach a stable temperature and ensure the accuracy of the temperature controller.

4. Gas supply:

a. Pass the mixed gas (oxygen and nitrogen) into the combustion chamber of the tester to ensure sufficient oxygen supply during combustion.

b. Adjust the oxygen concentration to meet the standard requirements and ensure the stability of the gas flow.

5. Ignition and combustion:

a. Use an ignition device to ignite one end of the sample and observe whether it can spontaneously ignite.

b. If the sample cannot spontaneously ignite, use an ignition device to ignite one end of the sample, make sure that the ignition source touches the sample, and observe whether the sample can continue to burn.

c. Record the time required to ignite the sample, and observe the characteristics of the combustion, such as the color of the flame, the speed of burning, etc.

6. Test result record:

a. According to the standard requirements, record the sample ignition time and burning time.

b. Calculate the oxygen index (LOI) value of the sample according to the burning length of the sample during the combustion process.

7. Clean and prepare for the next test:

a. Turn off the gas supply and ignition and wait for the test device to cool.

b. Clean the test fixture and fixtures in preparation for the next test.

It should be noted that the above steps are only a common Polymers Oxygen Index Test method, and the specific experimental steps may vary according to different test instruments and standard requirements. When performing the oxygen index test, it should be operated in strict accordance with relevant standards and specifications, and ensure the accuracy and stability of the test equipment. In addition, in order to obtain reliable test results, attention should also be paid to the influence of factors such as sample selection, preparation and handling.

2023-07-07 10:34