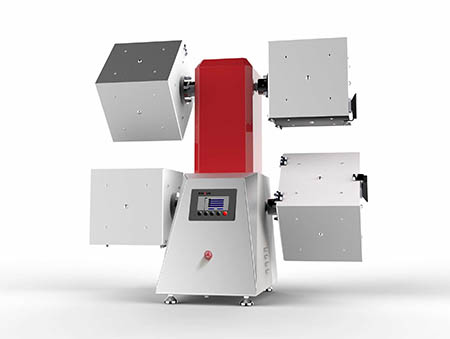

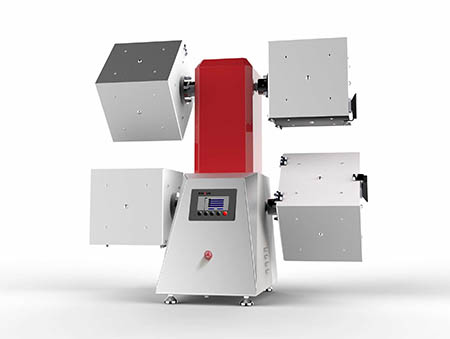

Introduction to the ICI Pilling Box Tester: What is it and how does it work?

The ici pilling box tester is an instrument used to evaluate the pilling performance of fabrics. Pilling refers to the appearance of small spherical fiber clusters on the surface of the fabric, usually caused by the friction of the fibers on the surface of the fabric during use or washing. The ici pilling box tester can simulate the friction of the fabric during use, and evaluate the quality and durability of the fabric by quantitatively evaluating the degree of pilling.

The ici pilling box tester works as follows:

1. Prepare the sample: Cut the fabric sample to be tested into small pieces of a specific size, and ensure that the surface of the sample is clean and free of contamination.

2. Install the sample: fix the sample on the test platform of the ici pilling box tester, and ensure that the surface of the sample is parallel to the test platform.

3. Friction test: Start the ici pilling box tester, make the friction head on the test bench contact the surface of the sample, and rub at a certain speed and time. Friction heads typically consist of a set of rotating cylinders or disks with a specific texture or material on the surface.

4. Observation and evaluation: After the friction test is completed, observe whether there is pilling on the surface of the sample, and evaluate and record according to the number, size and distribution of pilling. Samples are typically graded using a standardized pilling rating system to assess their pilling performance.

The advantage of the ici pilling box tester is that it can provide quantitative pilling evaluation results, making the comparison between different samples more objective and accurate. It is widely used in textiles, clothing, home textiles and other industries for quality control and product improvement purposes. Through the ici pilling box tester, manufacturers can evaluate the durability and service life of fabrics, so as to provide better products to consumers.

2023-06-29 10:37